PVC roll film with outer package and packaging method thereof

A packaging method and PVC film technology, applied in the field of plastic film products, can solve the problems of unfavorable mechanized operation, weak packaging, inconvenient handling, etc., and achieve the effects of easy mechanized operation, not easy to open, and not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

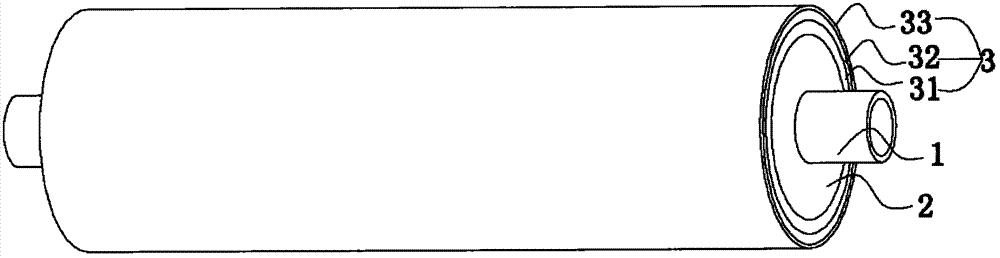

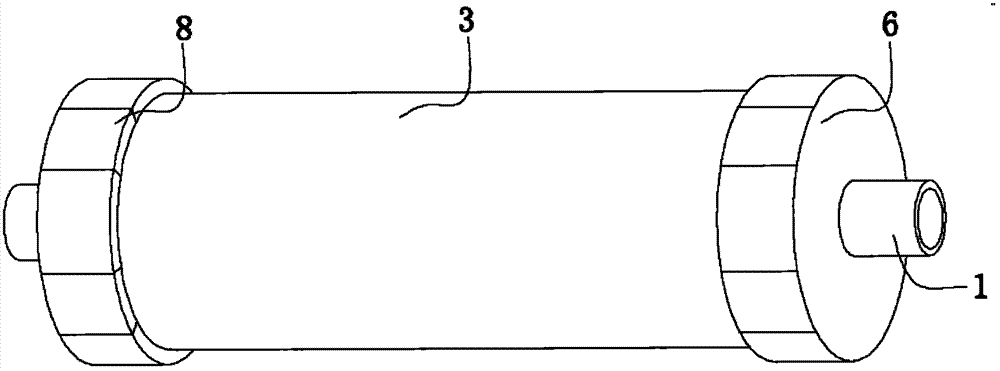

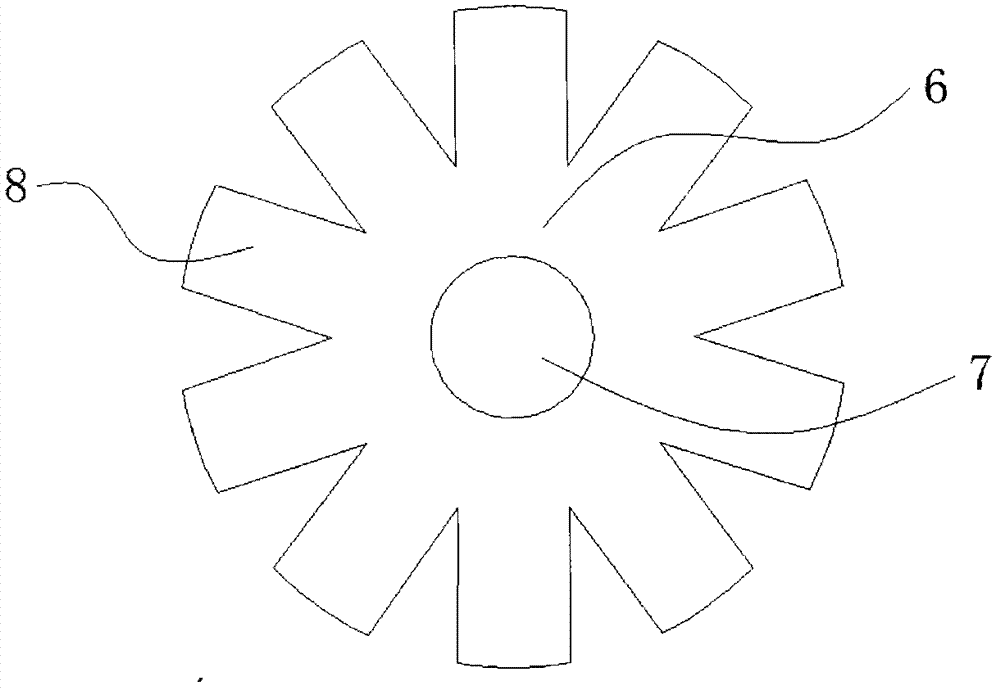

[0028] The invention provides a PVC roll film with outer packaging, such as figure 1 and figure 2 As shown, it includes a winding core 1, a PVC film 2 wound on the winding core 1, an outer packaging layer 3 and packaging components 6 located at both ends, the outer packaging layer 3 is wrapped on the outer surface of the PVC film 2, and the packaging component 6 passes through the roll The core 1 is installed at both ends of the PVC film 2 .

[0029] Corresponding to the PVC roll film with outer packaging, its packaging methods include:

[0030] Step 1: Wrap the outer packaging layer 3 on the outer surface of the PVC film 2, and fix the interface;

[0031] In this step, the outer packaging layer 3 can be tiled on the desktop, and then the PVC film is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com