Magnetic winding roller

A winding roller and magnetic technology, applied in the field of textile machinery, can solve the problems of wasting resources, affecting the quality of fabrics, and unusable fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

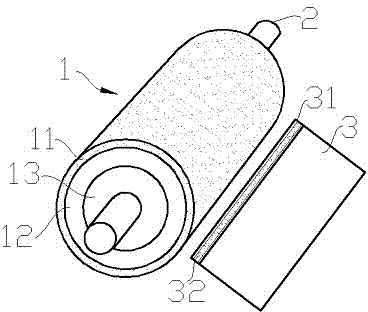

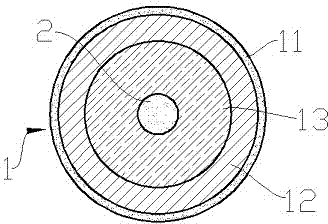

[0013] exist figure 1 , figure 2 In the shown embodiment of the invention, the magnetic rewinding roller includes a rewinding roller body 1, the center of the rewinding roller body 1 is provided with a rotating shaft 2, and the surface of the rewinding roller body 1 is attached with a magnetic Material coating11.

[0014] Above-mentioned magnetic rewinding roller, the edge place of the cloth 3 that will be rewound is covered with piping strip 31, and a slender thin iron sheet 32 is placed in described piping strip 31, when cloth 3 is close to winding roller body 1 At this time, the iron sheet 32 in the binding strip 31 and the magnetic material coating 11 on the surface of the roller body 1 attract each other, so that the cloth 3 is automatically adsorbed on the surface of the winding roller body 1, eliminating the need for manual winding. cloth process.

[0015] The above-mentioned magnetic rewinding roller, the rewinding roller roll body 1 is divided into inner and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com