Continuous cutting equipment for CRT (cathode ray tube) display glass

A CRT display and cutting equipment technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of low efficiency, unfavorable CRT glass flow, automated operation, low work efficiency of workers and equipment, etc., to achieve high efficiency effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

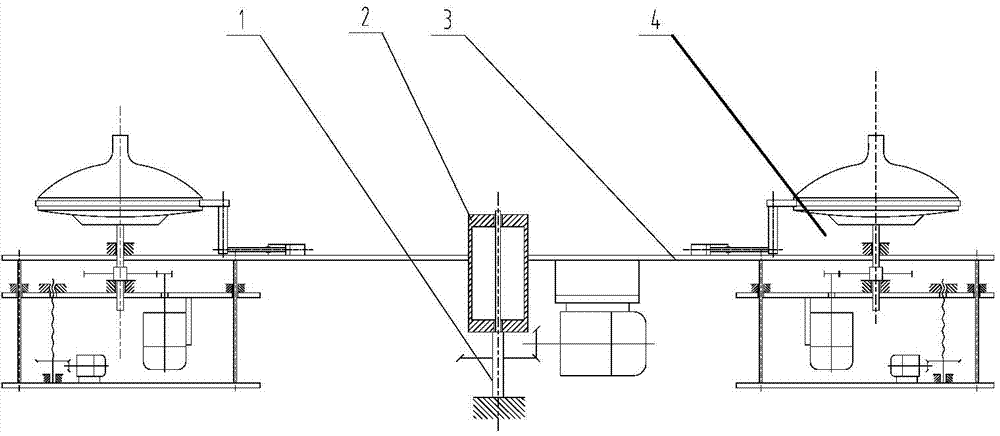

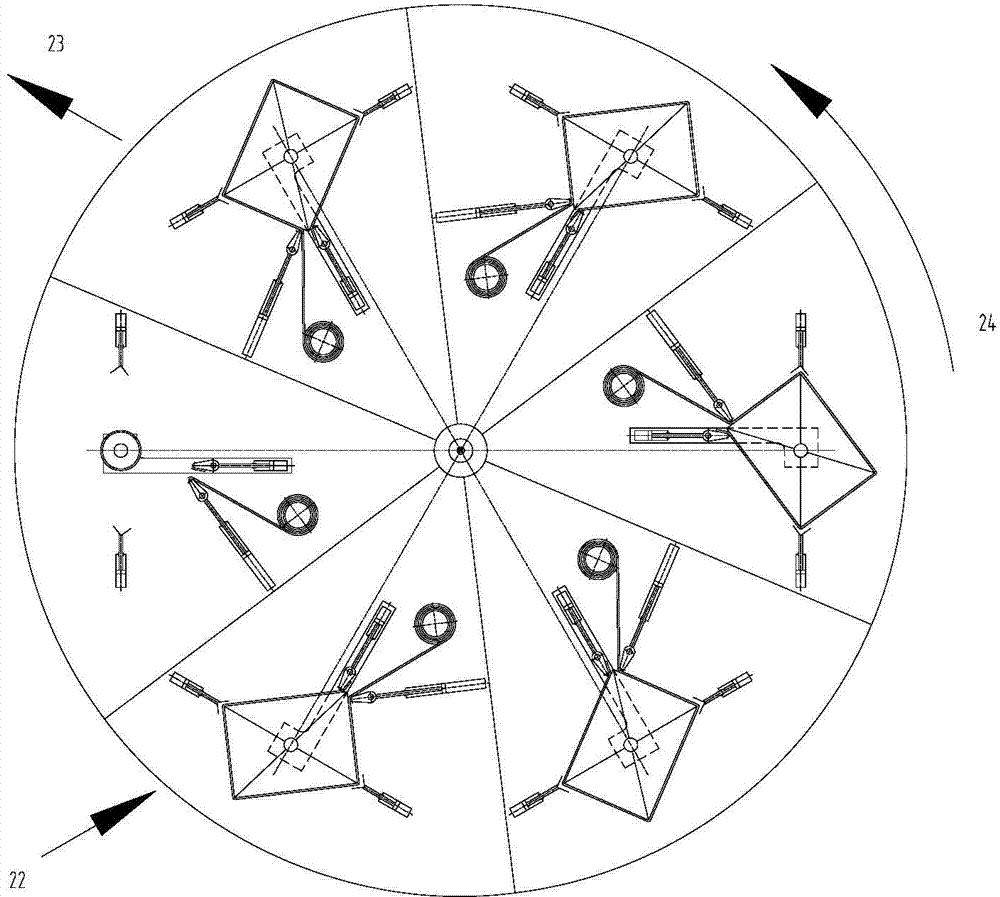

[0016] The CRT display glass continuous cutting equipment of the present invention comprises a vertical shaft 1 fixed on the ground, and a rotary table 3 movably connected to the vertical shaft 1 through a shaft sleeve 2 . The CRT display cutting device 4 is evenly distributed and fixed on the rotary table 3 according to the circumference, and the CRT display cutting device 4 includes a lifting and rotating device, a centering device, and a winding device.

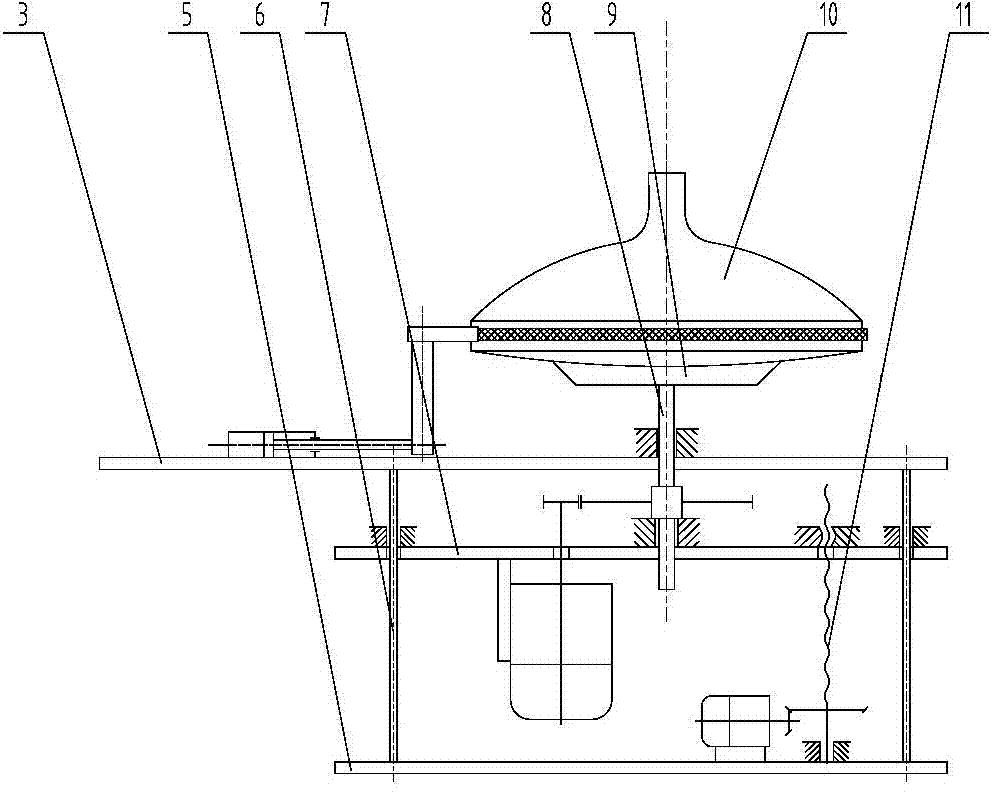

[0017] Among them, the structure of the lifting and rotating device is as follows: the base plate 5 is fixed below the rotary table 3 through the guide column 6; the movable platen 7 is located between the rotary table 3 and the base plate 5, and is movably connected with the guide column 6; the lifting table can be controlled The lifting device 11 for the up and down movement of the plate 7 is fixed on the bottom plate 5; the suction cup support shaft 8 is hinged on the lifting table 7, and passes through the rotary table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com