Automatic winding device used for external anti-corrosion glass fiber cloth of pipeline

A glass fiber cloth, winding device technology, applied in general control systems, program control in sequence/logic controllers, instruments, etc., can solve the problem of difficult to ensure uniform application of asphalt, coal tar enamel or epoxy powder, and difficult to achieve anti-corrosion The problems of uniform fiber cloth, close winding, and high working intensity can achieve the effect of high automation, reasonable structure and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

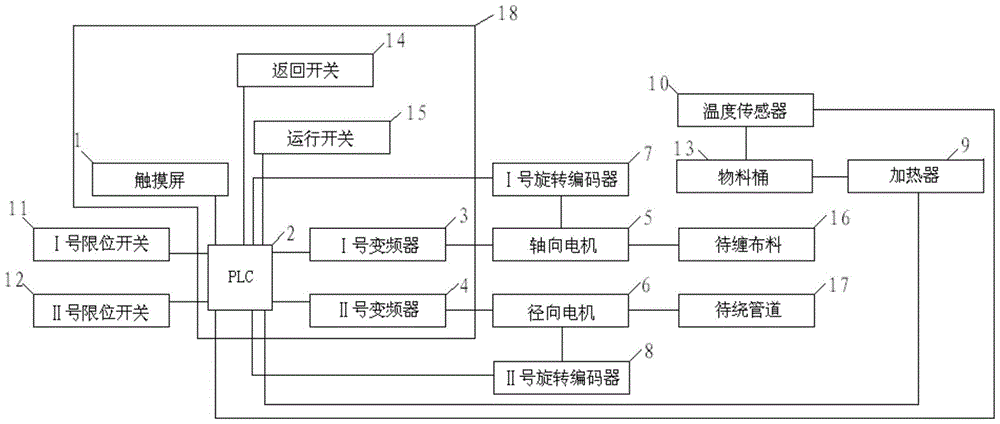

[0011] The main structure of the automatic winding device for anti-corrosion glass fiber cloth outside the pipeline involved in this embodiment includes a touch screen 1, a programmable logic controller (hereinafter referred to as PLC) 2, a No. I frequency converter 3, a No. II frequency converter 4, an axial Motor 5, radial motor 6, rotary encoder Ⅰ 7, rotary encoder Ⅱ 8, heater 9, temperature sensor 10, limit switch Ⅰ 11, limit switch Ⅱ 12, material barrel 13, return switch 14. The operation switch 15, the fabric to be wrapped 16, the pipe to be wrapped 17 and the control cabinet 18, the No. Frequency converter 3 and No. Ⅱ frequency converter 4 are used to electrically connect and control axial motor 5 and radial motor 6 respectively. The output shaft of axial motor 5 is sleeved with material bucket 13 and cloth to be wrapped 16 through bearings. The output shaft of 6 is connected with the pipe 17 to be wound through the bearing sleeve, and the electrical information between...

Embodiment 2

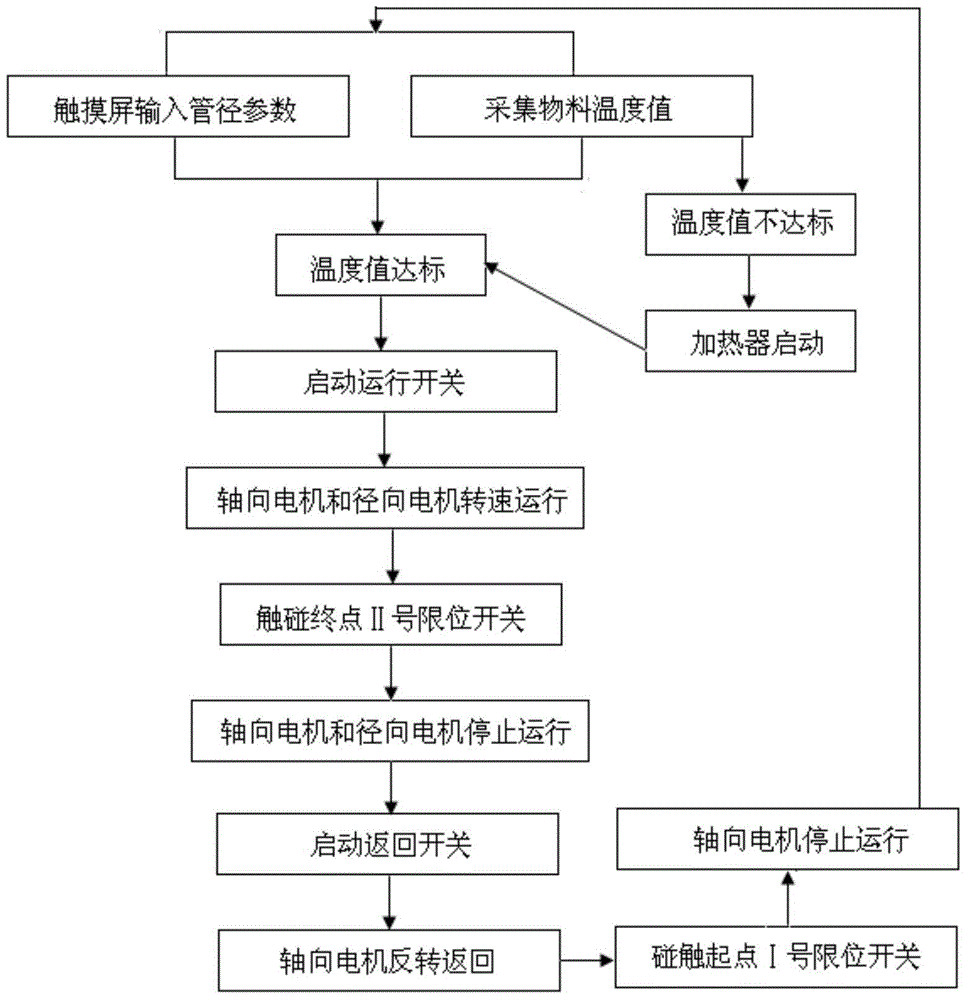

[0014] This embodiment is implemented in the automatic winding device of Embodiment 1, and the automatic winding method involved specifically includes the following steps:

[0015] (1) Manually measure the pipe diameter parameter (i.e. diameter parameter) of the pipeline 17 to be wrapped and input it into PLC2 through the touch screen 1, and PLC2 calculates the rotating speed of the radial motor 6 after receiving the pipe diameter parameter, and simultaneously collects it through the temperature sensor 10 The temperature value of the material in the material barrel 13, if the temperature value does not reach the predetermined parameter, the PLC2 controls the heater 9 to heat the material barrel 13, and if the temperature value reaches the predetermined parameter, then the PLC2 is in the state to be started;

[0016] (2) Manually start the running switch 15 so that PLC2 receives the running command, and PLC2 sends commands to No. I frequency converter 3 and No. II frequency conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com