Manual automatic integrated locking and unlocking mechanism

An unlocking mechanism, manual and automatic technology, which is applied in the direction of mechanical equipment, fixing devices, fluid pressure actuating devices, etc., can solve the problems of inability to realize manual and automatic free switching, large manual operation force, and bulky mechanism, so as to save energy, Effect of increasing output force and overcoming resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

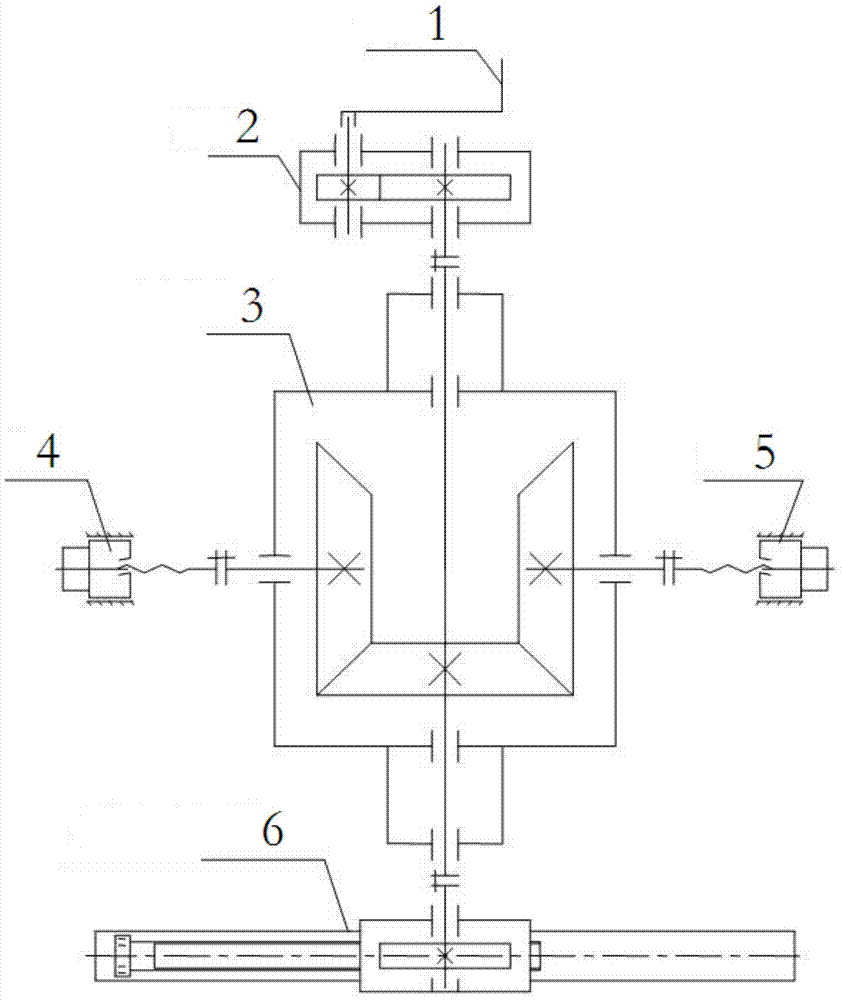

[0018] as attached figure 1 As shown, the present invention provides a manual and automatic integrated locking and unlocking mechanism, including a handle 1, a reduction box 2, a gear diverter 3, a left locking pin 4, a right locking pin 5 and a rack and pinion cylinder 6, wherein , a rack and a gear are arranged in the rack and pinion cylinder 6, the rack is driven by external air pressure or oil pressure in the cylinder, and moves linearly along the axis of the cylinder body, the gear is arranged above the rack, and the rack and pinion cylinder 6 is in the initial state , the gear and the rack are in a non-meshing state;

[0019] There are three bevel gears inside the gear diverter 3, one of which is a transmission gear, and the other two are output gears, and the output gears mesh with the transmission gear at the same time;

[0020] The left locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com