Three-dimensional inspection sample plate for taper milling cutter

A technology of taper and template, which is applied in the field of three-dimensional inspection templates of taper milling cutters, can solve the problems of difficult alignment of the tool tip point, difficulty of detecting the size of the bottom diameter of the tool, and inaccurate alignment of the tool, so as to achieve convenient on-site operation and improve detection The effect of precision and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

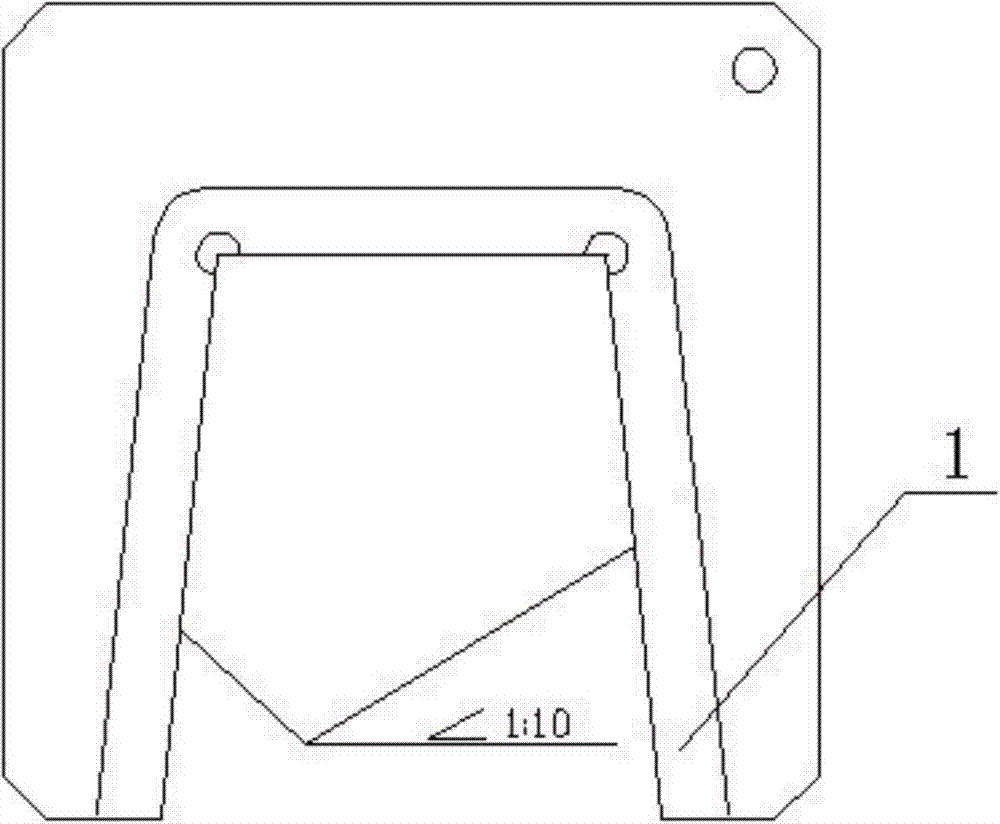

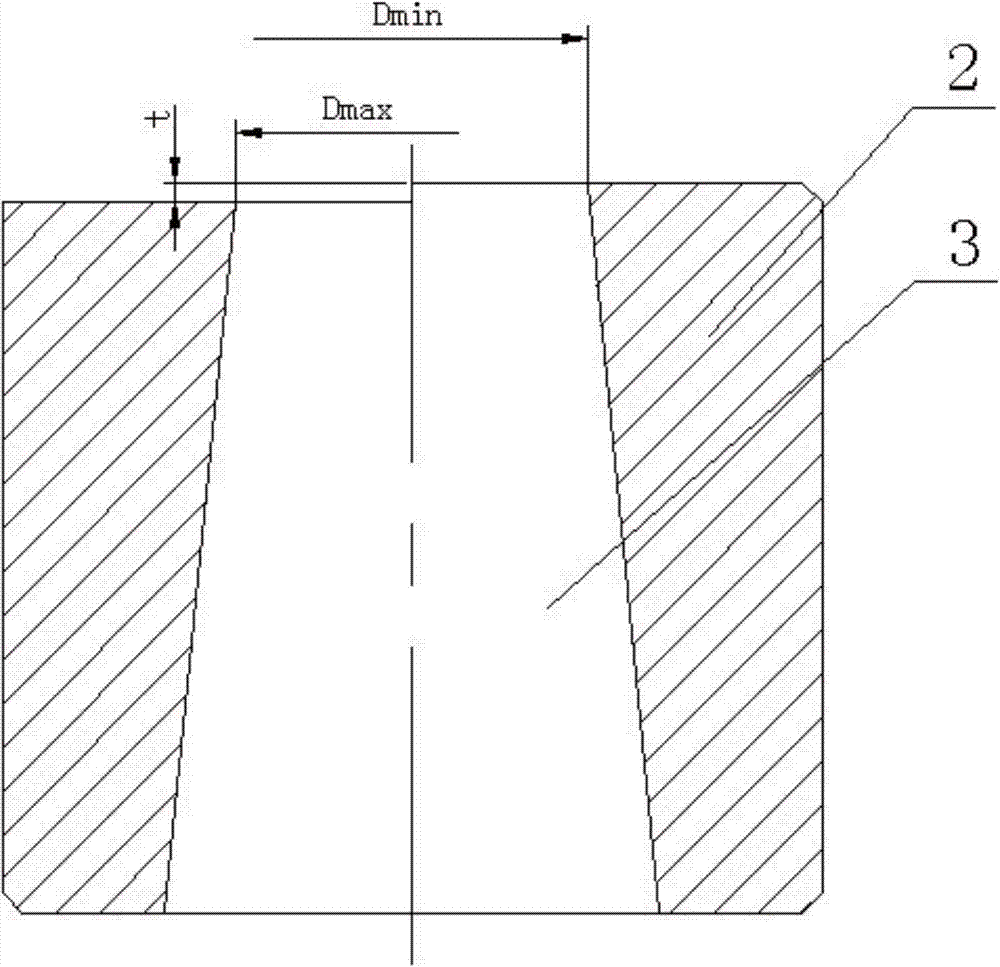

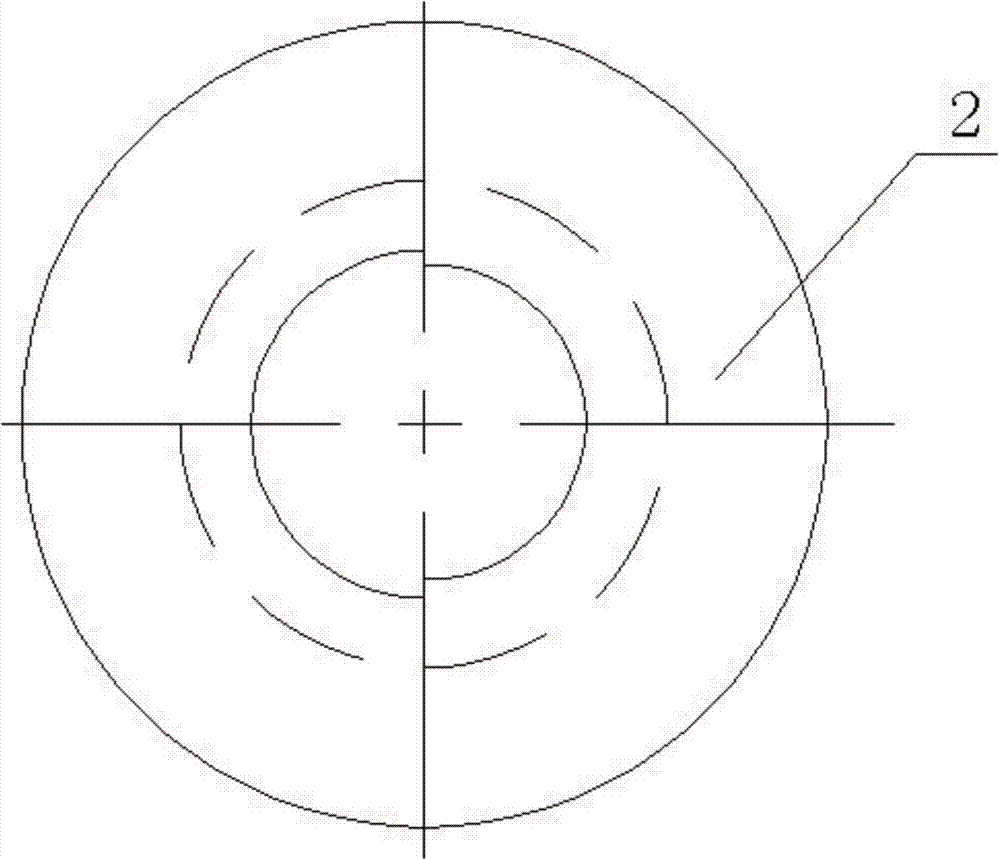

[0017] like Figure 2-Figure 4 The three-dimensional inspection template of a tapered milling cutter mainly includes a template main body 2 , and a taper hole 3 penetrating through the template main body 2 is opened on the template main body 2 .

[0018] In the following, a specific tapered milling cutter with a taper of 1:5 is taken as an example to describe in detail. The blade portion of the tapered milling cutter has a taper of 1:5, and the lower difference of the diameter tolerance of the circle where the tip point of the tapered milling cutter is located is Dmin , the upper difference of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com