A flange defect automatic detection device and detection method

An automatic detection device and automatic detection technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problem of high personnel detection level and experience requirements, and the impact of manual intervention Larger, unable to be verified and other problems, to achieve the effect of simplifying the detection workflow, reducing technology dependence, and easy to master the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

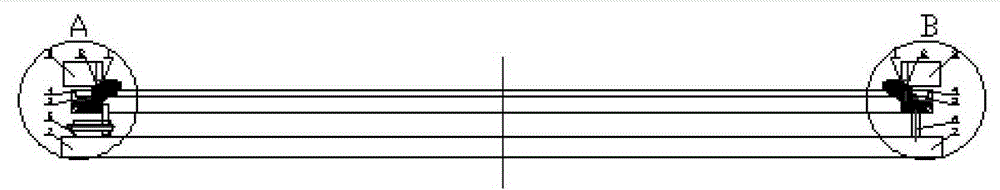

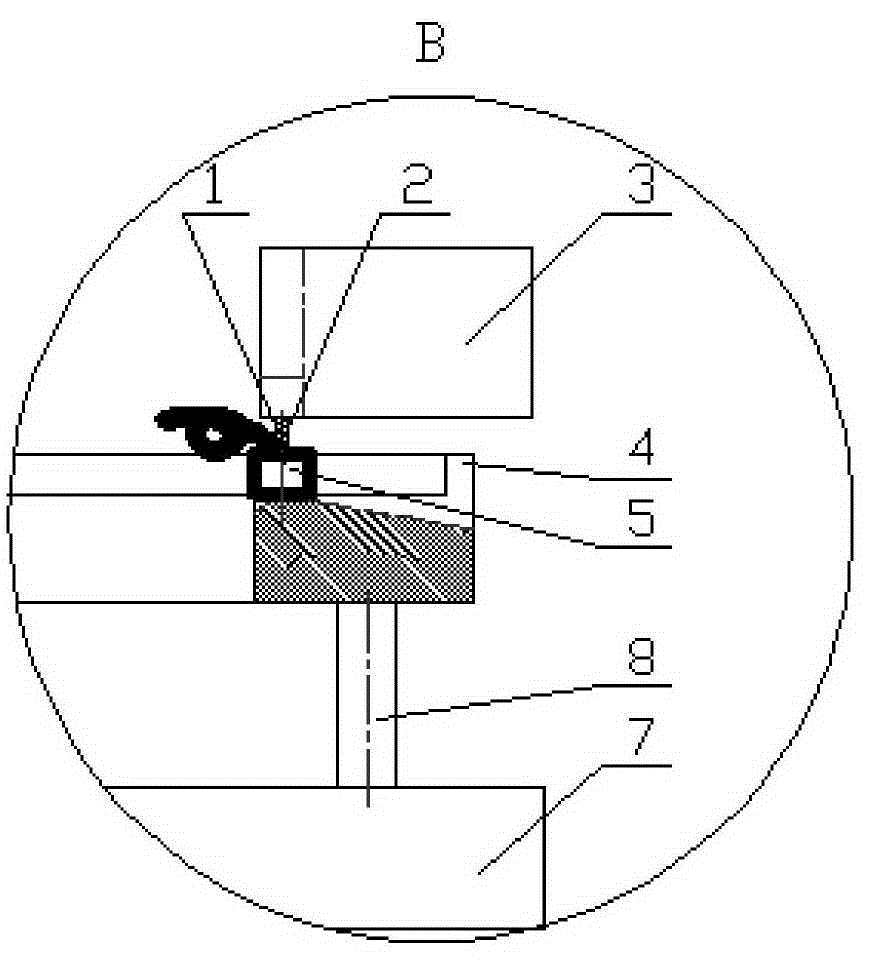

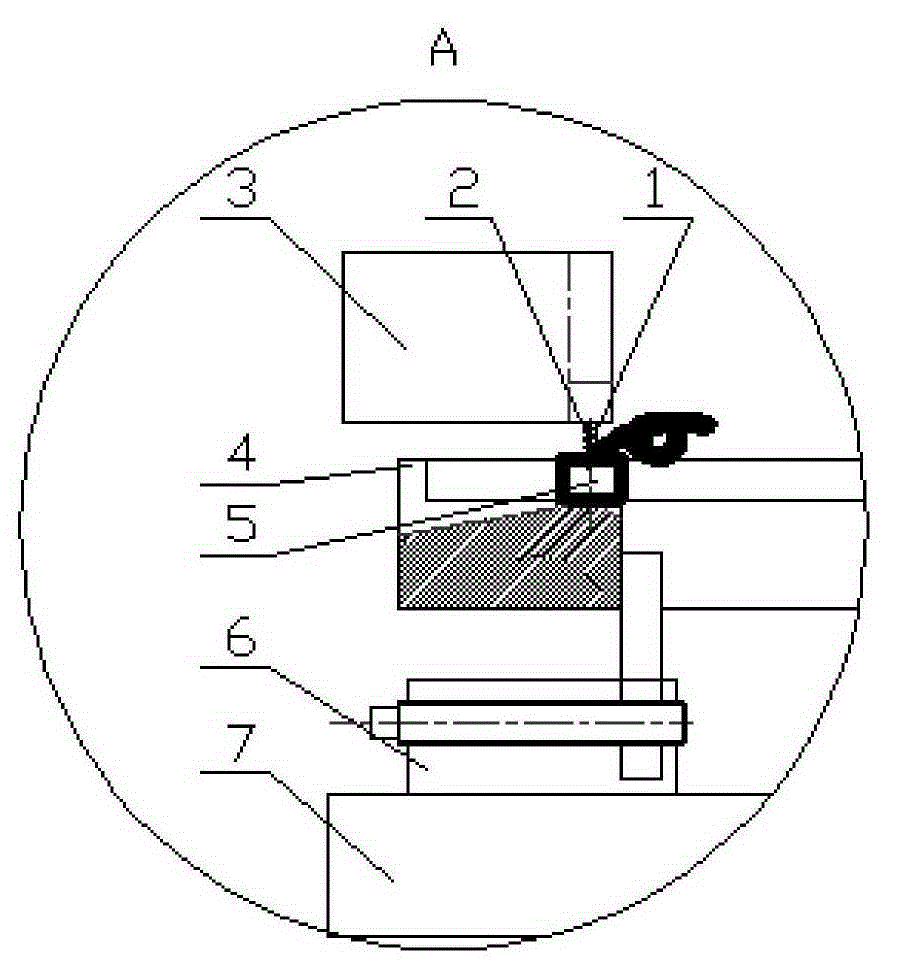

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] The present invention mainly combines the phased array technology into the defect detection of the flange, and through a large number of experiments, designs an automatic flange defect detection device that can reasonably combine the phased array technology into the flange defect detection, and through the experiment Demonstration, but also to determine its feasibility.

[0041] Phased array is a modern detection method that uses advanced electronic technology to focus the energy emitted by the chip to achieve strong energy penetration. Phased array probes consist of a series of individual elements, like many small conventional ultrasound probes integrated into one probe. Each chip has its own connectors, delay circuits, and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com