Stator pressing tool for motor

A technology for pressing stators and tooling, applied in the direction of manufacturing stator/rotor bodies, etc., can solve the problems of small size and assembly difficulty, deformation and dispersion of small servo motors, and achieve the effects of simple structure, improved production efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

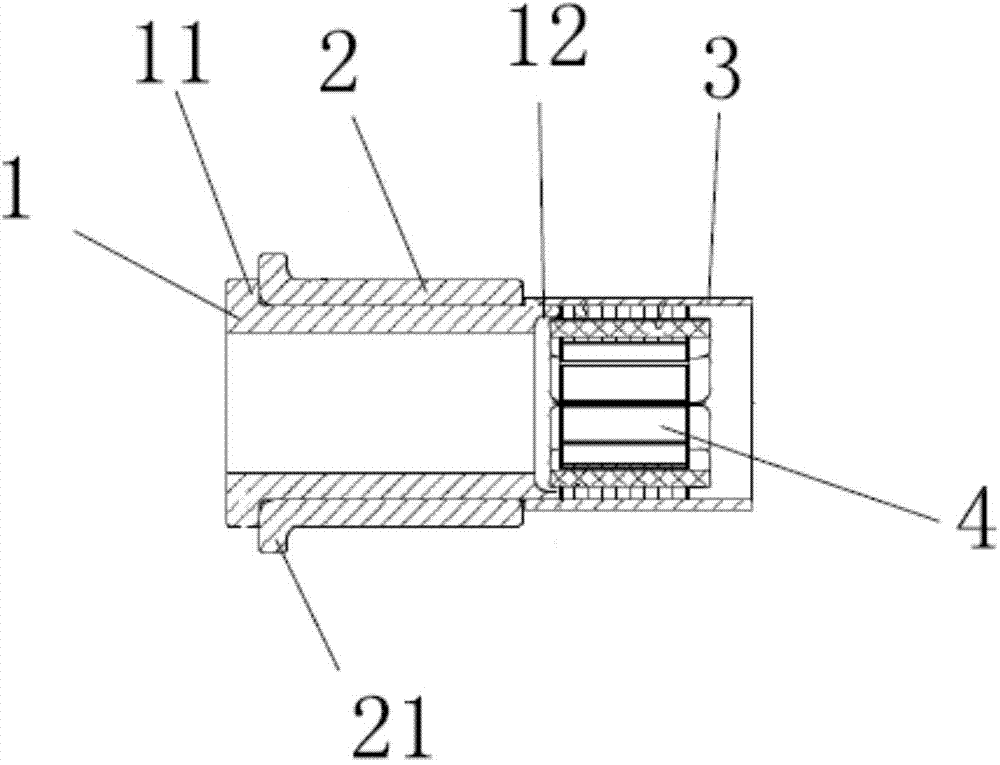

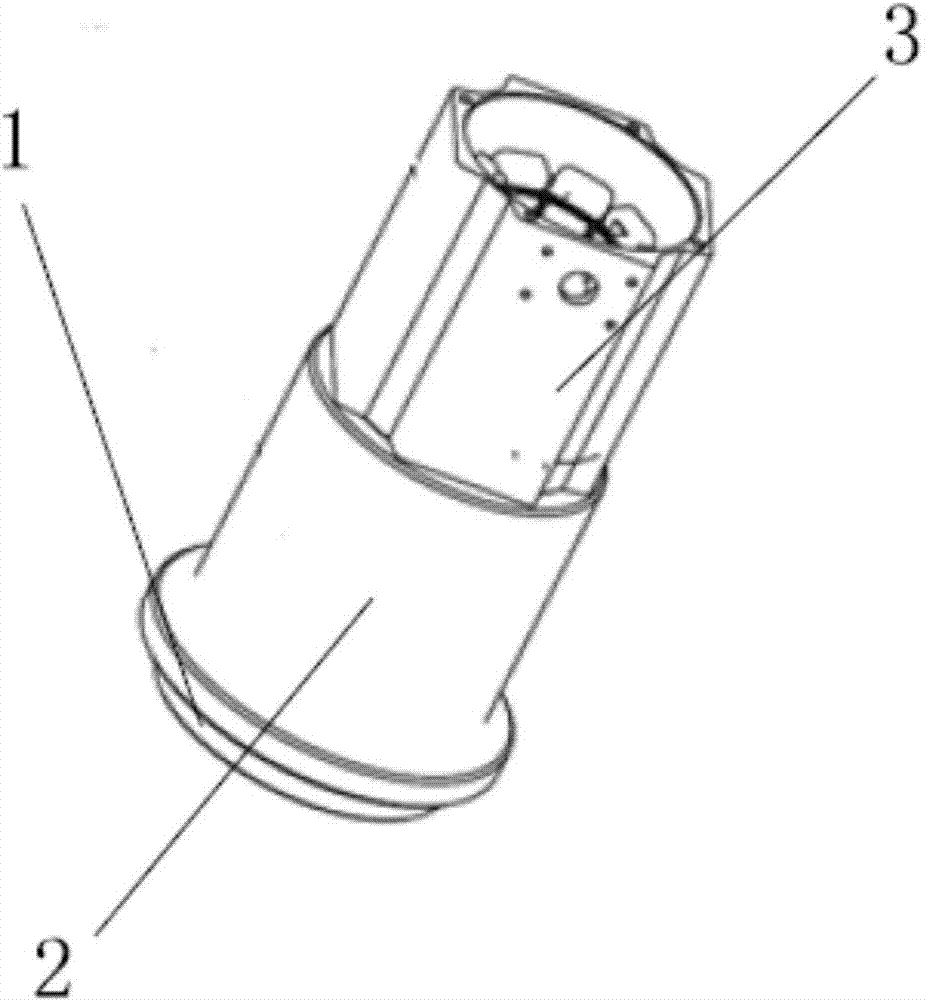

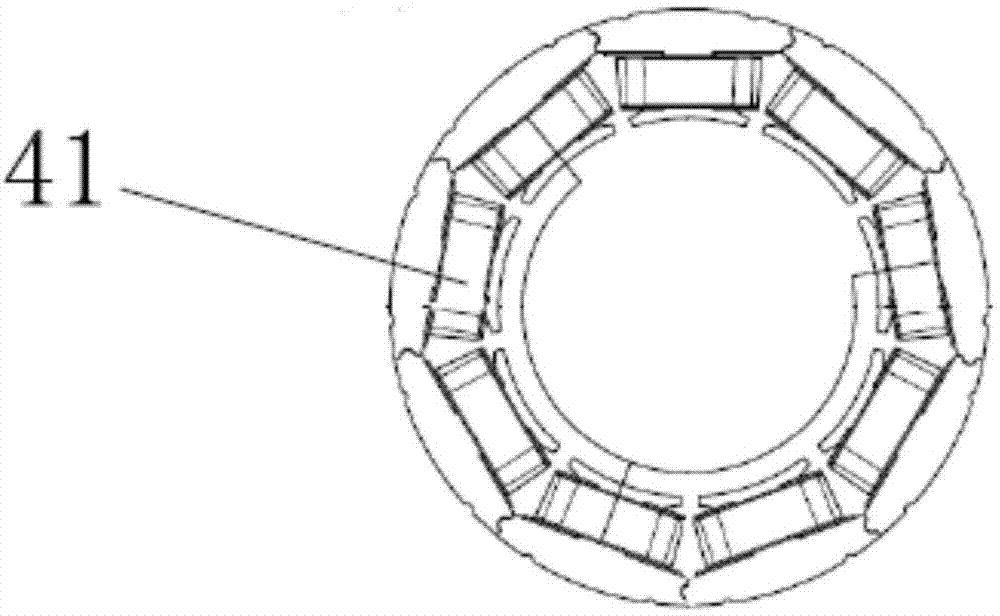

[0019] First, nine stator cores 41 are spliced and inlaid around the center of the circle to form a circular wound stator 4, and then copper wires 5 are wound on the wound stator 4, and at the same time, insulating punches are sleeved on the wound stator 4 6. After completing the above preparatory work, first connect the hoop stator sleeve 2 to the outer surface of the stator sleeve 1, then insert the winding stator 4 into one end of the stator sleeve 1, and then install the assembly on the press On the machine, the stator housing 3 is then heated to ensure that the temperature of the stator housing 3 reaches 180°C, and finally the stator housing 3 is pressed on the outer ring of the assembly by a press.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com