A height-adjustable arc gate membrane steel support

A technology of arc gate and steel support, applied in ceramic molding machines, manufacturing tools, mold auxiliary parts, etc., can solve the problem of difficult reuse of materials, and achieve the effect of improving service life, improving accuracy and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

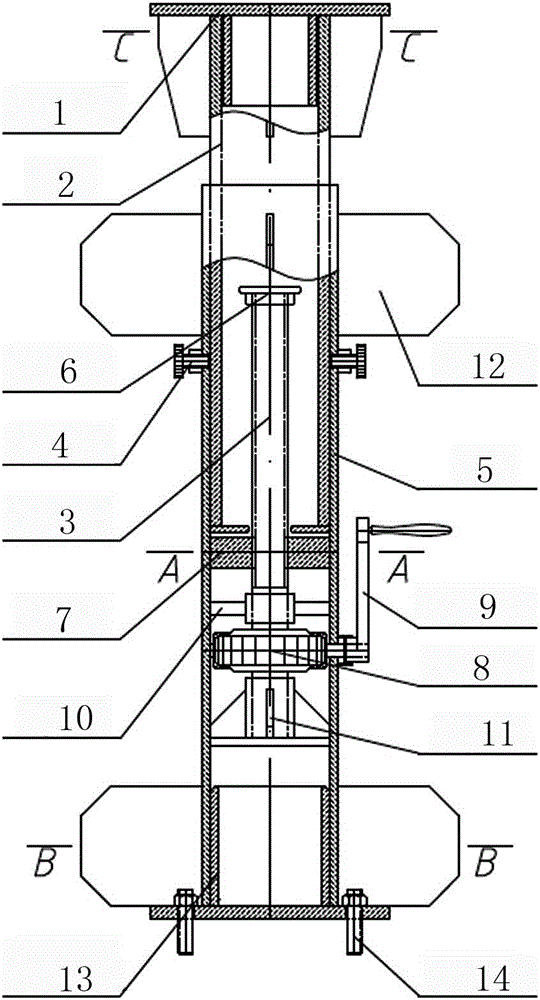

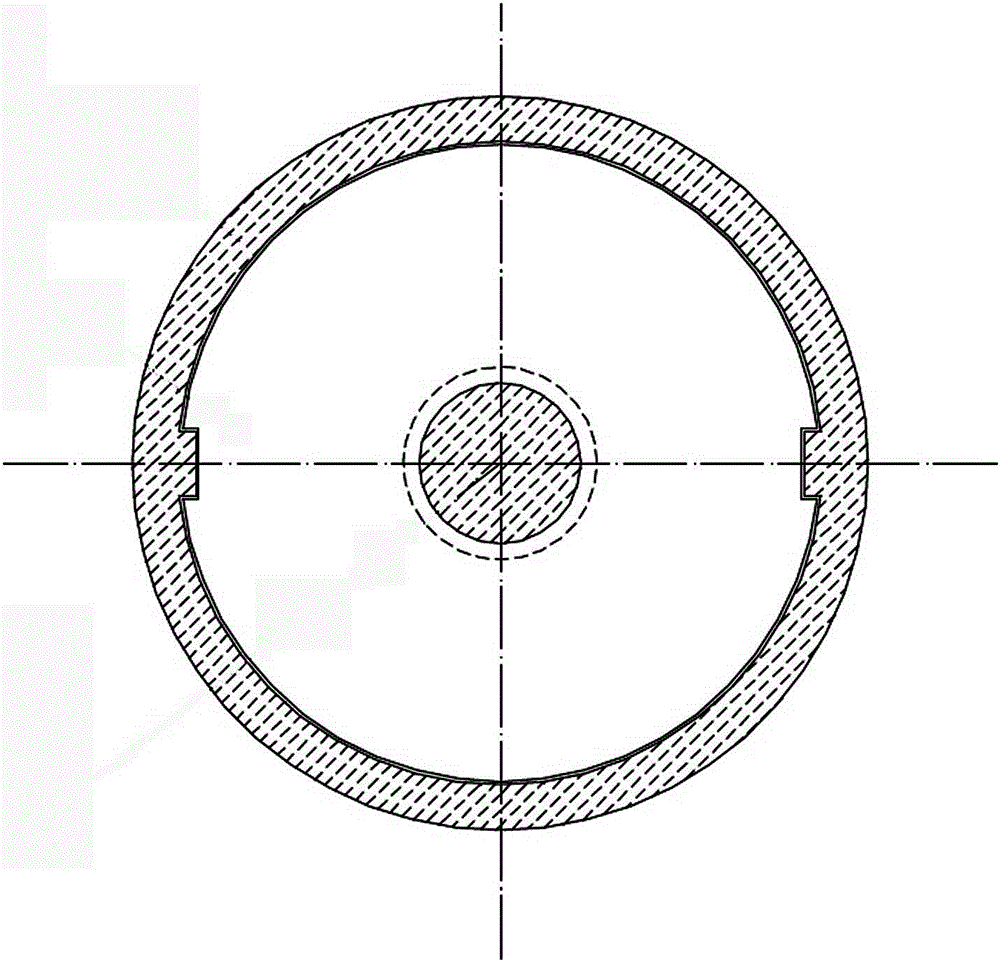

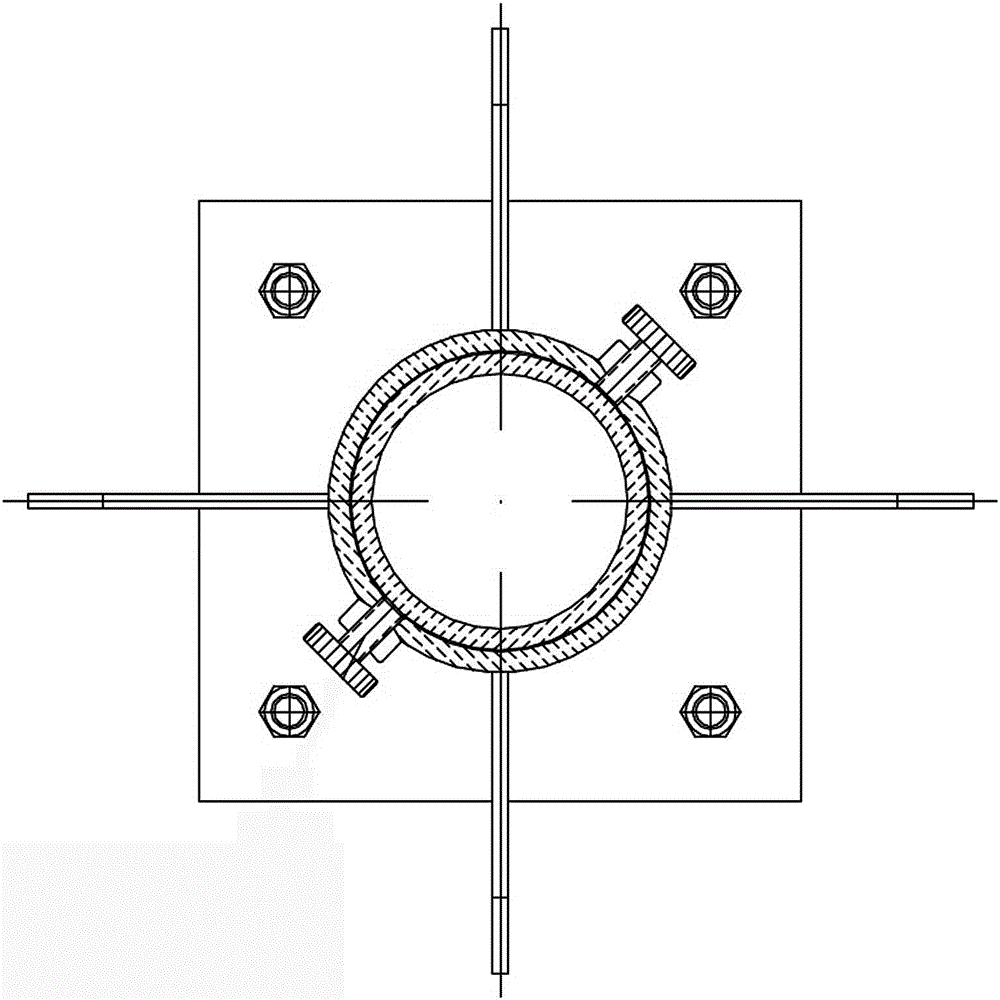

[0021] like Figure 1-5 Shown is a height-adjustable arc-shaped gate membrane steel support, the height-adjustable arc-shaped gate membrane steel support includes a steel support, the top of the steel support is a top seat 1, and the bottom of the top seat 1 is a push rod 2, The inside of the ejector rod 2 is provided with a transmission device 3, and the outside of the ejector rod 2 is provided with a sleeve 5, and the sleeve 5 is provided with a locking device 4, and a pressing plate 12 is installed above the locking device 4 on the sleeve 5. 2 The upper end of the internal transmission device 3 is provided with a limit device 6, the lower part of the transmission device 3 is provided with a jacking block 7, and a positioning sleeve 10 is provided below the jacking block 7, and the transmission device 3 passes through the positioning sleeve 10 and is located in the positioning sleeve 10. The worm gear 8 below is connected, and the worm gear 8 is controlled by the rocking rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com