Automatic ink-jet printing system

An automatic, printing head technology, applied in printing, typewriters, etc., can solve the problems of difficulty in meeting standardization requirements, labor and time consumption, and uneven work quality, and achieve good consistency, labeling work standards, and high labeling accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below through embodiments in conjunction with the accompanying drawings.

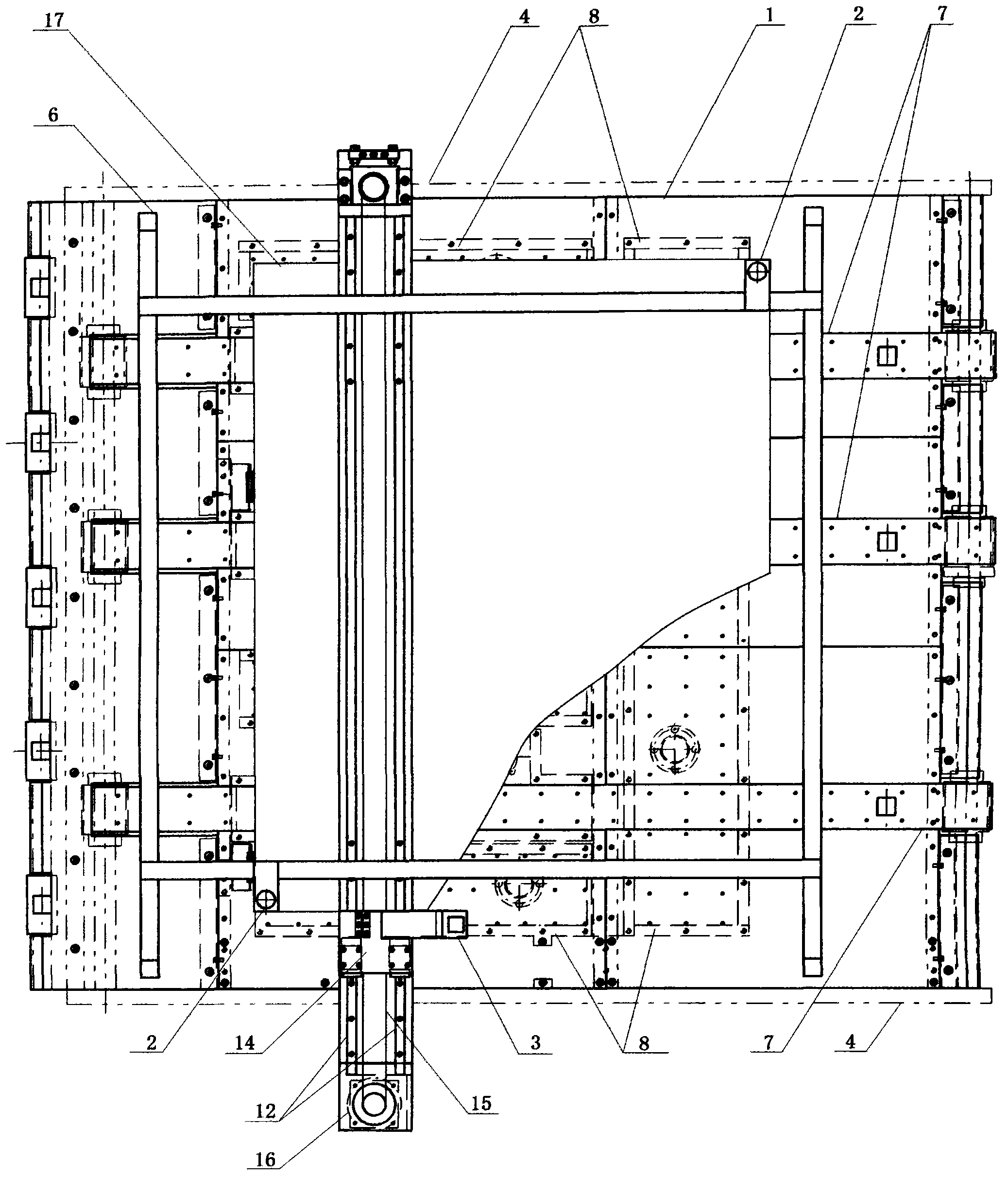

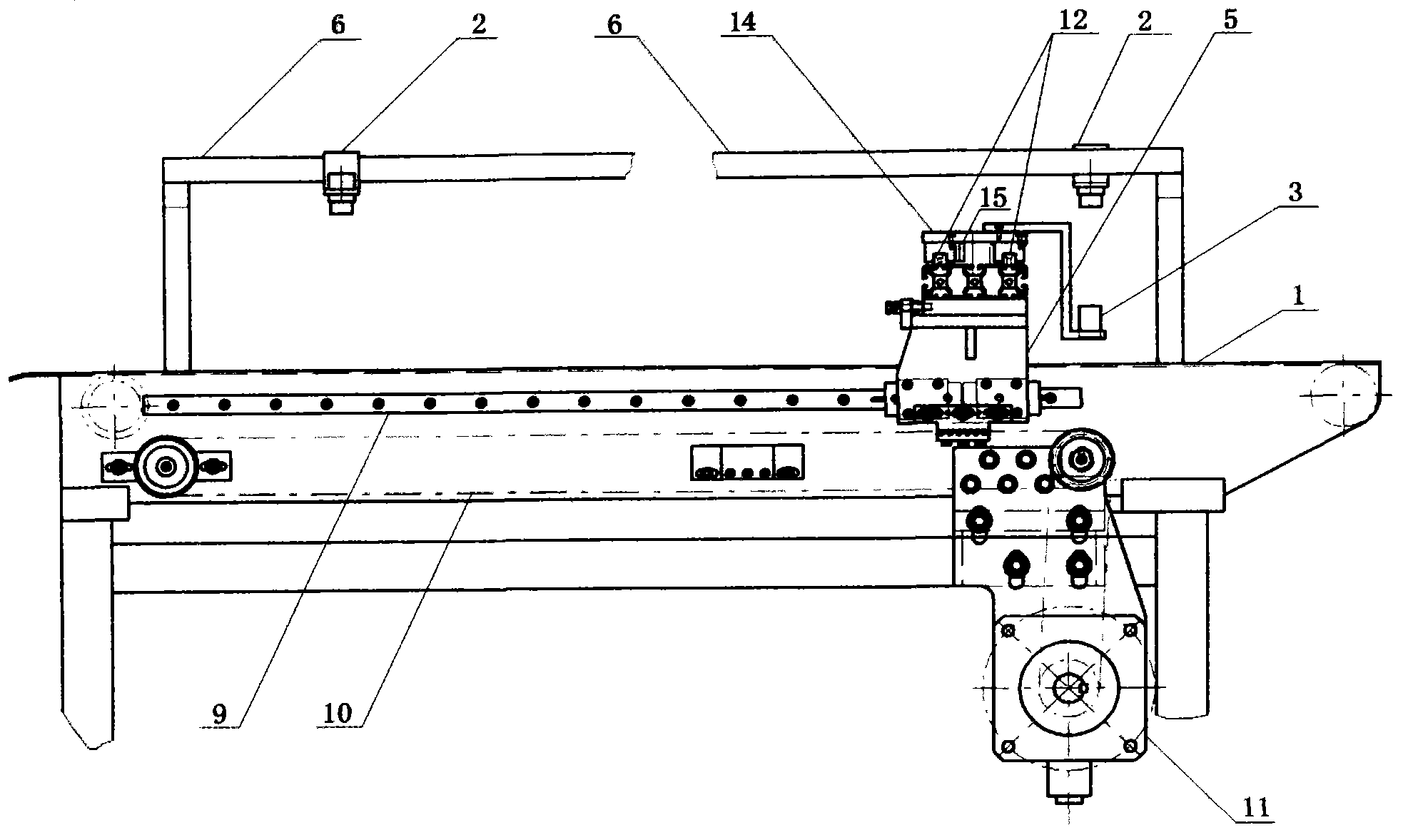

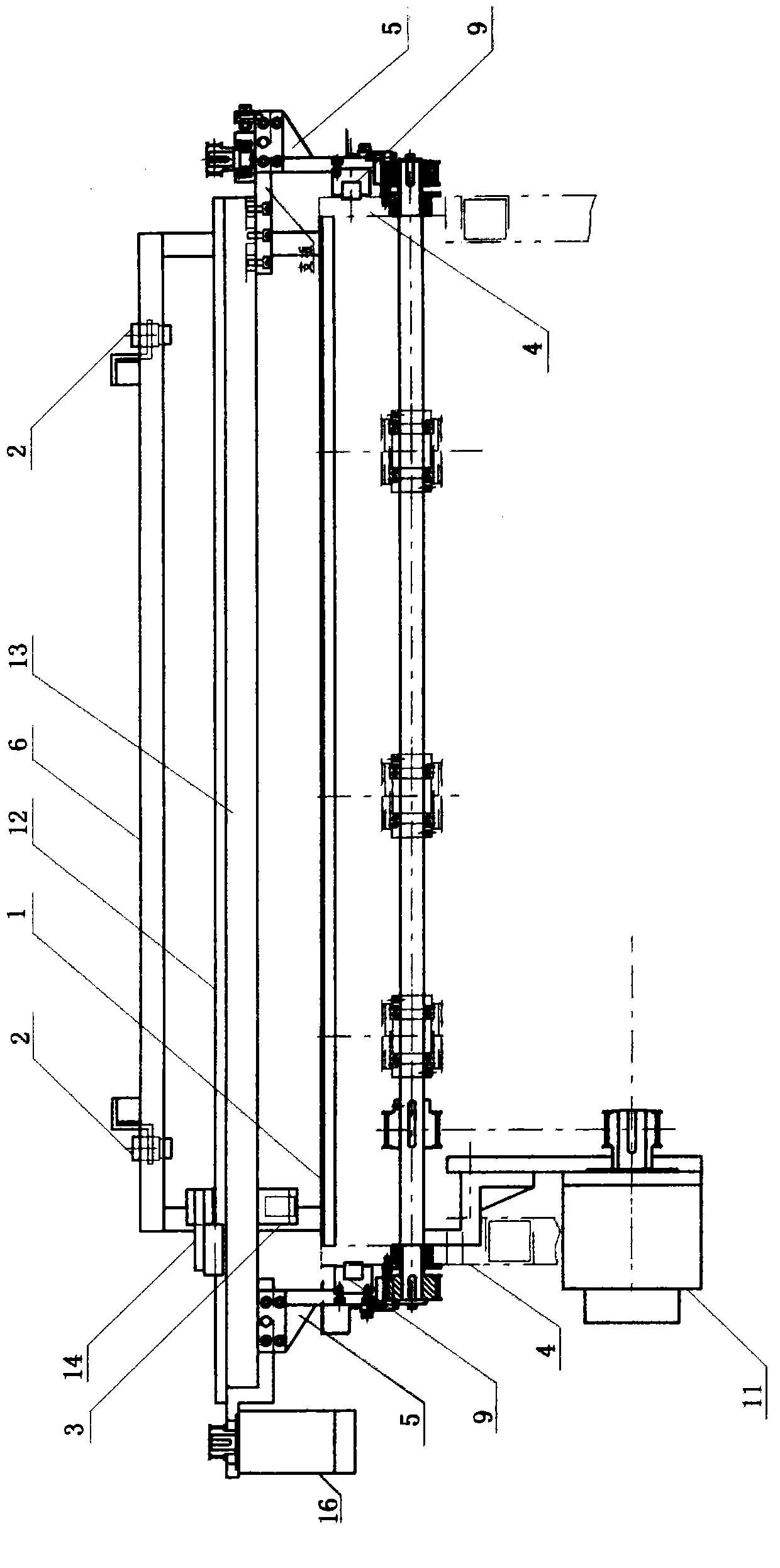

[0020] Such as Figure 1-3 As shown, the automatic printing system of the present invention includes a positioning printing platform 1, a longitudinal movement device, a lateral movement device, a camera 2, and a printing head 3. The positioning printing platform 1 is fixed between two wallboards 4 of the whole machine, and the longitudinal movement The device is slidably arranged on both sides of the positioning printing platform 1, and the lateral movement device is slidably arranged on the connecting frame 5 of the longitudinal movement device. The head 3 is fixed on the transverse movement device.

[0021] The positioning printing platform 1 is composed of a plurality of air suction belts 7 and a plurality of parallel front and rear air suction plates 8, and each air suction belt 7 and each air suction plate 8 has a number of air suction hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com