Method for manufacturing carrier tape

A manufacturing method and carrier tape technology, applied in packaging, etc., can solve the problem of reduced operability and achieve the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

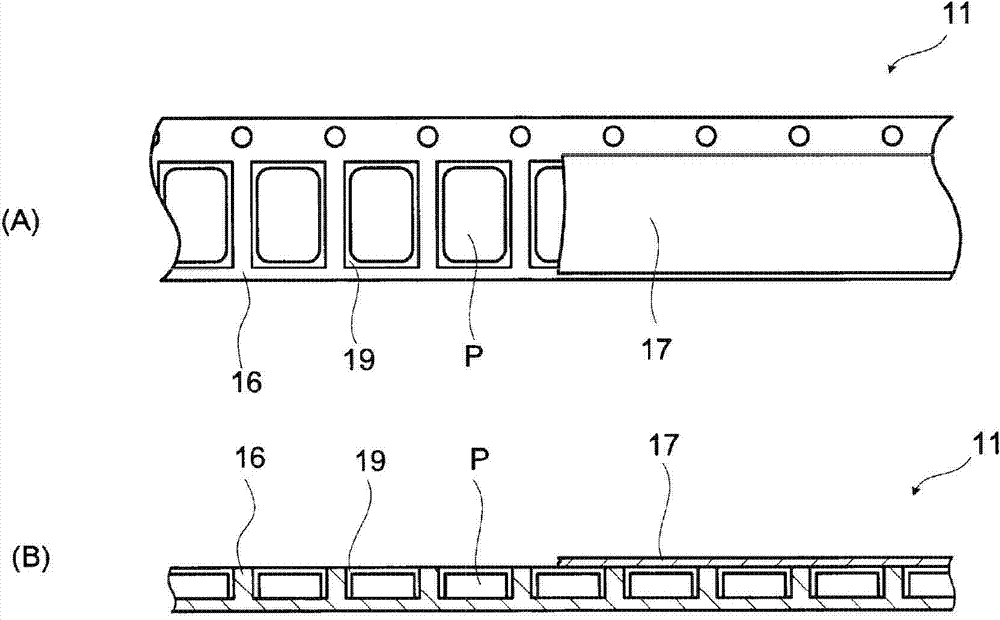

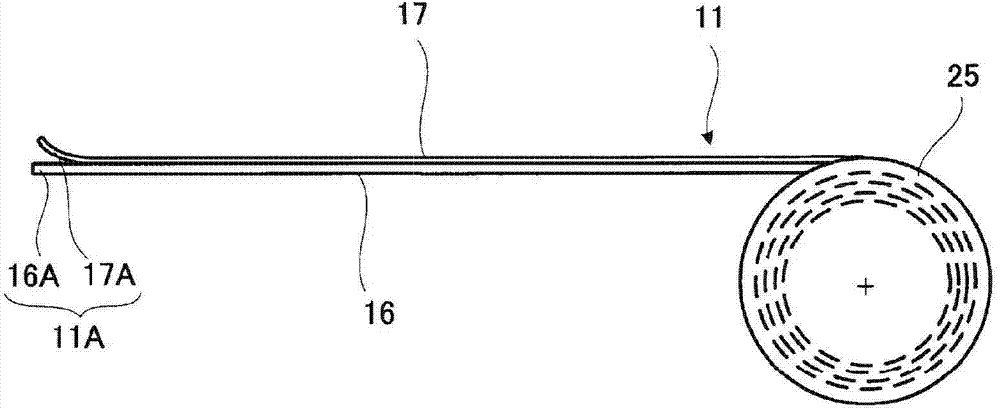

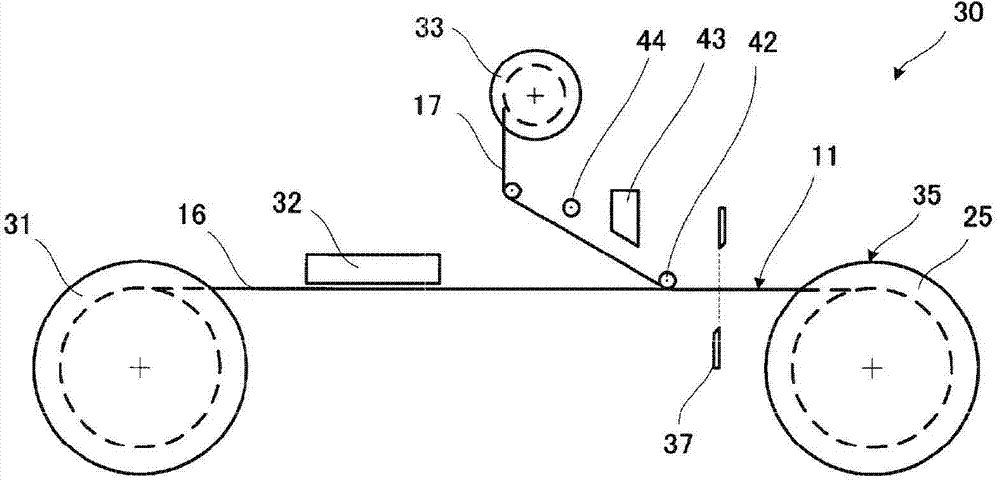

[0049] Such as figure 1 (A) and figure 1 As shown in (B), the carrier tape 11 is comprised from the tape main body 16, the cover film 17, and several electronic components P. The belt main body 16 is an elongated body, and a plurality of recesses 19 are formed at predetermined intervals in the longitudinal direction. Electronic components P are housed in each of the plurality of recesses 19 . A cover film 17 is attached to the tape main body 16 to prevent the electronic components P stored therein from flying out.

[0050] Here, the electronic component P is, for example, a multilayer ceramic capacitor with a length of 2.0 mm, a width of 1.25 mm, and a height of 0.6 mm. The dimensions of the tape body 16 of the carrier tape 11 are, for example, a thickness of 1 mm, a width of 8 mm, and a length of 17 mm, and the pitch of the recesses 19 formed at predetermined intervals is, for example, 4 mm. The material of the belt main body 16 is paper or resin. The dimensions of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com