Method for unloading load pulley from tower crane

A technology of load block and tower crane, which is applied in the direction of load block, load hanging components, transportation and packaging, etc., to achieve the effect of reducing operation risk and saving procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

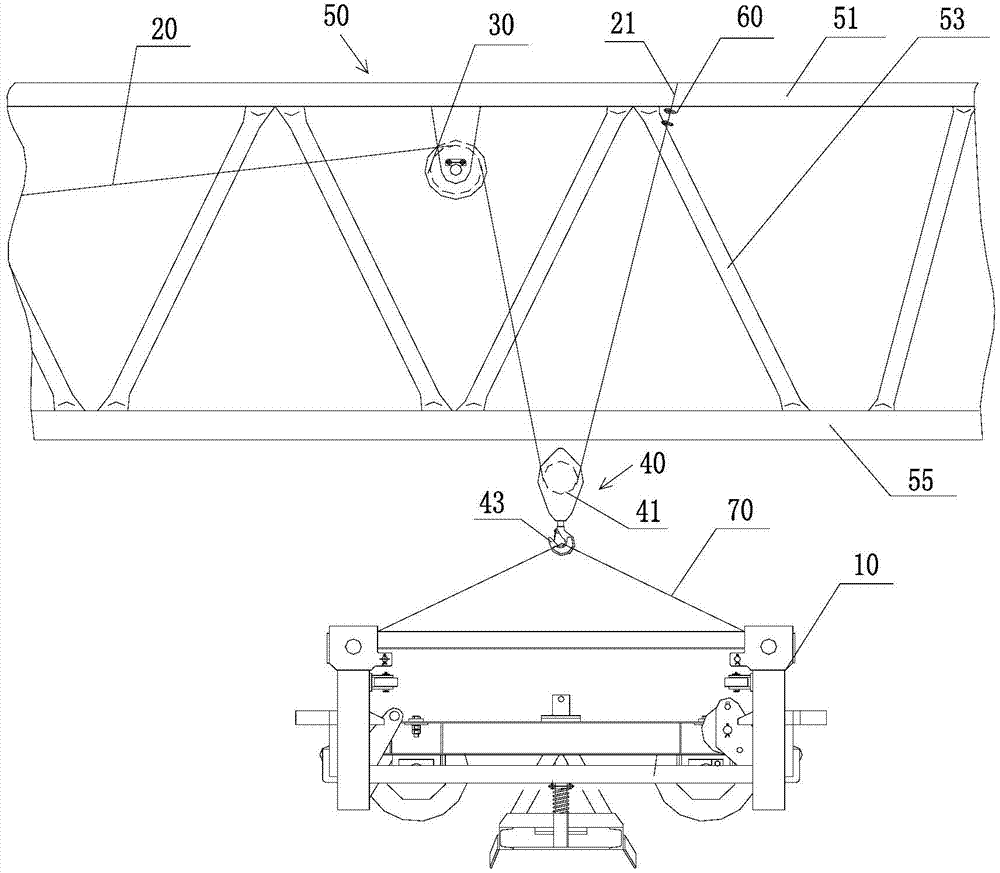

[0022] Such as figure 1 As shown, the present invention provides a method for unloading a load block from a tower crane. In order to avoid the use of auxiliary, independent large-scale lifting equipment that does not belong to the tower crane, such as truck cranes or For other tower cranes, etc., the core idea of the method for unloading the load block from the tower crane provided by the present invention is to use the hoisting wire rope 20 on the tower crane as a mechanism for lifting the load block 10. The height of the truck crane or other tower cranes cannot dismantle the problem of the load block 10. On the other hand, it can avoid dismantling the arm tip of the boom and reduce the risk of unloading the load block.

[0023] In view of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com