Cross beam and stand column connecting structure

A technology for connecting structures and beams, used in building structures, buildings, etc., can solve problems such as structural instability, difficult disassembly of beams, and difficulty in springing into pin holes, and achieves stable installation structure, seismic strength and system safety. The effect of improved shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

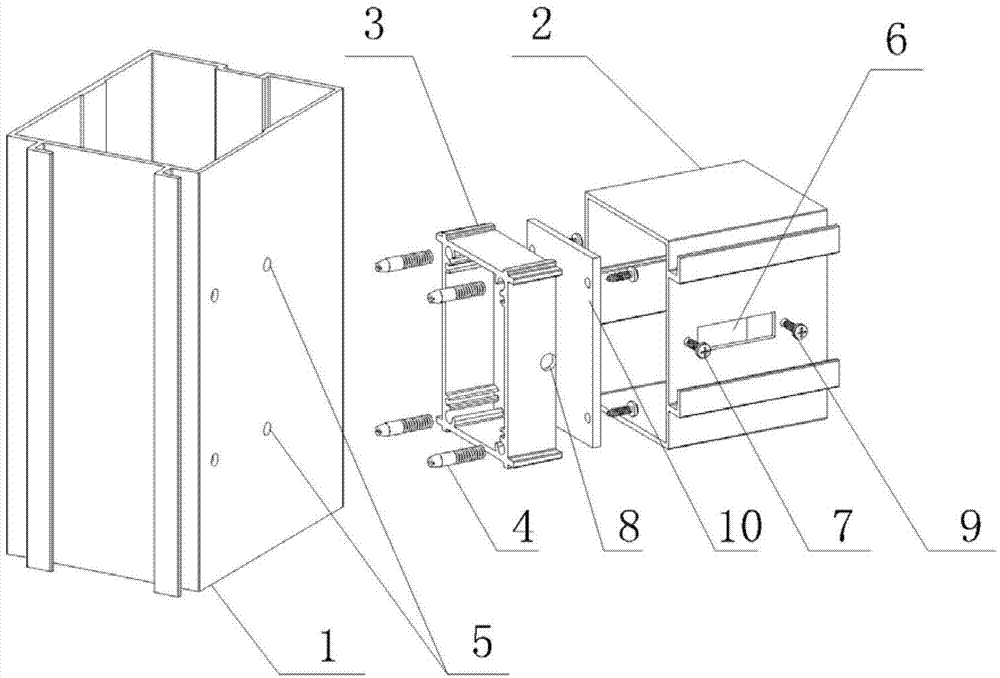

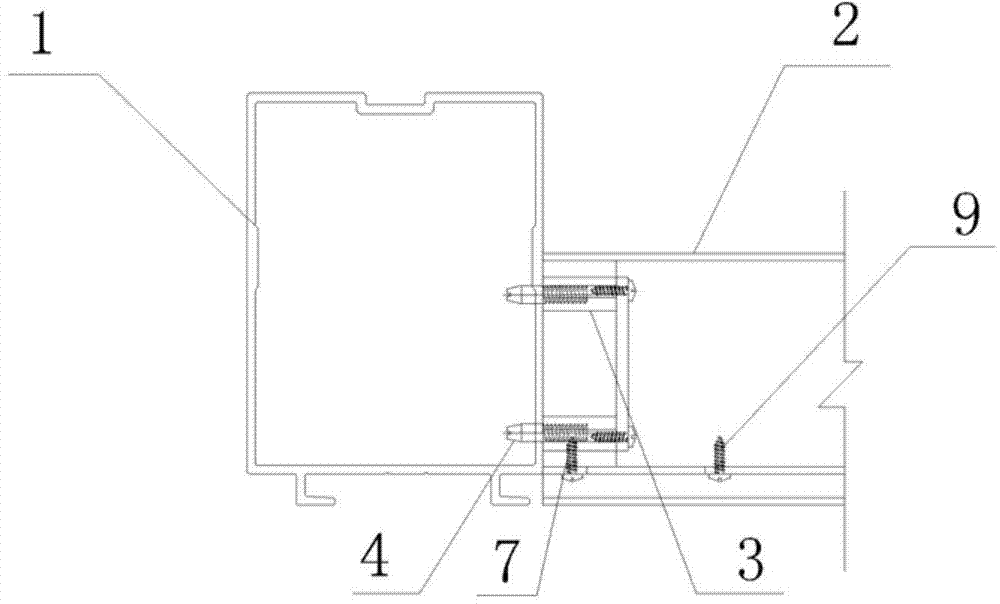

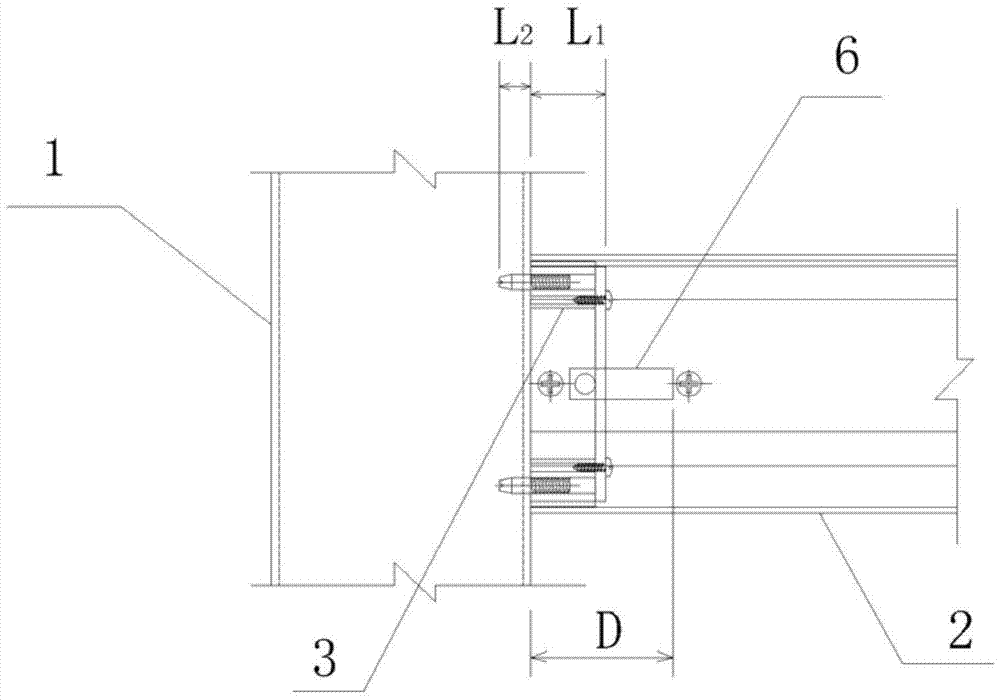

[0032] like Figure 1-Figure 3 As shown, a connection structure between a beam and a column, it includes: a column 1, a beam 2 connected to the column 1, a movable latch seat 3 is provided in the end of the beam 2, and a plurality of bolt seats are arranged on the latch seat 3 A bolt 4; a pin hole 5 corresponding to the bolt 4 is provided on the column 1; a through hole 6 penetrating the side wall is provided on the side wall at the end of the beam 2.

[0033] Wherein, the bolt seat 3 is a square frame surrounded by four side plates, and the bolt 4 is arranged at the same end of the square frame. When actually connecting the beam 2 and the column 1, first align the pin 4 with the pin hole 5, then insert a push rod into the through hole 6, and make the push rod lean against the back of the pin seat 3, and then use a hammer to hit the push rod Insert the bolt 4 into the pin hole 5 to realize the connection between the beam 2 and the column 1 . In this embodiment, in order to i...

Embodiment 2

[0040] like Figure 4 As shown, a connection structure between a beam and a column, it includes: a column 1, a beam 2 connected to the column 1, a movable latch seat 3 is provided in the end of the beam 2, and a plurality of bolt seats are arranged on the latch seat 3 A bolt 4; a pin hole 5 corresponding to the bolt 4 is provided on the column 1; a through hole 6 penetrating the side wall is provided on the side wall at the end of the beam 2.

[0041] This embodiment provides a beam-to-column connection structure, which is basically the same as Embodiment 1, the difference is that the bolt 4 is a smooth pin, and the bolt seat 3 is provided with a mounting hole for installing the pin. The pin is bonded to the mounting hole by adhesive.

Embodiment 3

[0043] like Figure 5 , Image 6As shown, a connection structure between a beam and a column, it includes: a column 1, a beam 2 connected to the column 1, a movable latch seat 3 is provided in the end of the beam 2, and a plurality of bolt seats are arranged on the latch seat 3 The bolt 4; a pin hole corresponding to the bolt 4 is provided on the column 1 .

[0044] This embodiment provides a connection structure between a beam and a column, which is basically the same as that of Embodiment 1, the difference being that the through hole in Embodiment 1 is replaced by a U-shaped opening 11, and a U-shaped opening exposed on the pin seat 3 is provided. 11 outer handle 12.

[0045] When actually connecting the beam 2 and the column 1, first align the pin 4 with the pin hole, and then push or tap the handle 12 to insert the pin 4 into the pin hole to realize the connection between the beam 2 and the column 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com