FRP bar connection device, connection method and anchor rod

A connecting device and casing technology, which is applied in the installation of bolts, earthwork drilling, structural elements, etc., can solve the problems of easy damage of joint parts, and achieve the effect of environmental protection and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

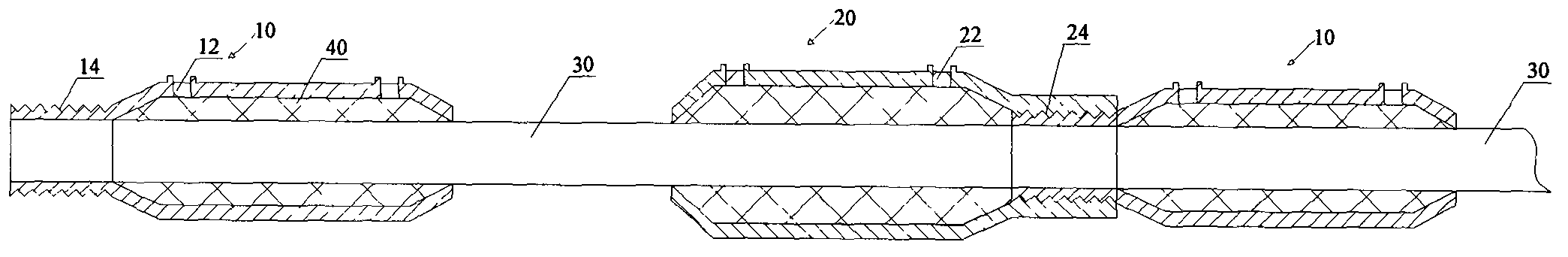

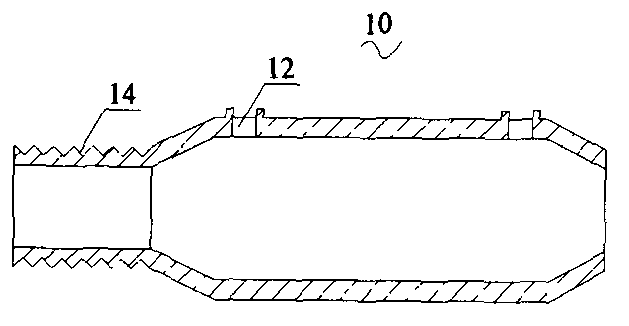

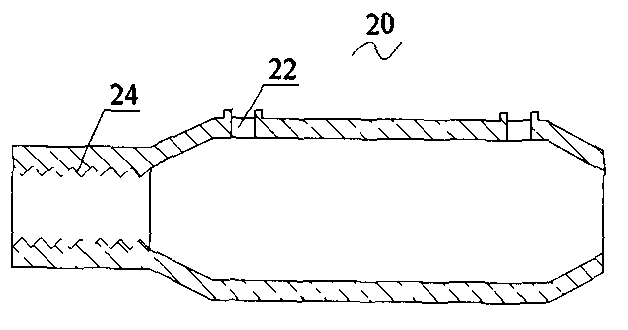

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] FRP is the abbreviation of Fiber Reinforced polymer (fiber reinforced material), generally including GFRP, CFRP, AFRP and other fiber reinforced plastics.

[0024] An FRP tendon connection device, the related parts include a first hollow sleeve 10 and a second hollow sleeve 20 . Such as figure 2 As shown, one end of the first hollow sleeve 10 is provided with an external thread 14, and there are one or more through holes on the inner wall according to the amount and efficiency of the grouting material, and figure 2 Shown are two through holes forming a first external channel 12 into which grouting compound can be injected. Such as image 3 As shown, one end of the second hollow casing 20 is provided with an internal thread 24, and the internal thread 24 is spirally matched with the external thread 14 of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com