Grinding shoe for underground milling in oil field

A technology for oil field wells and shoe grinding, which is applied in wellbore/well components, earthwork drilling and production, etc. It can solve problems such as low grinding and milling efficiency, excessive wear of the grinding shoe center, abnormal use of mud bag, etc., and achieve good working stability , Improve the milling speed and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

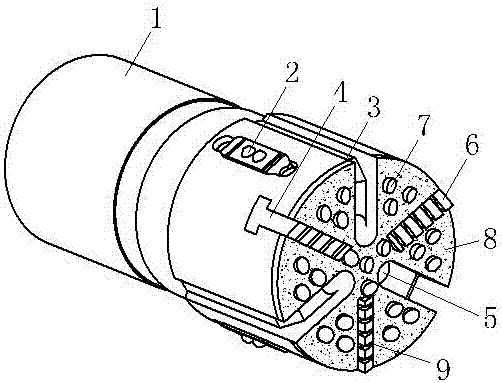

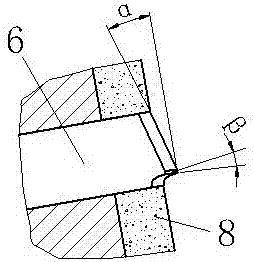

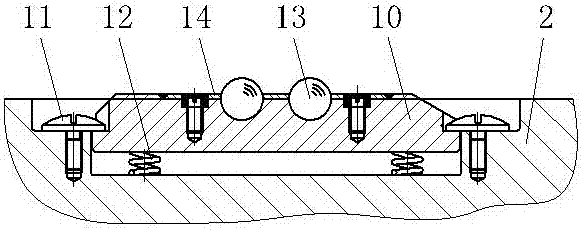

[0020] Embodiments of the present invention: a method for making a grinding shoe for underground milling in an oil field according to the present invention can be implemented on the basis of the existing grinding shoe. The method includes a grinding shoe body 1. During production, the grinding shoe body 1 is made into a cylindrical shape, and a hard alloy column 7 is fixed on the bottom of the grinding shoe body 1 in a conventional manner, and a group of centralizers with balls 2 are evenly distributed on the cylindrical surface of the grinding shoe body 1 along the circumference, and made The balls on the centralizer 2 with balls can roll, and at the same time, a set of T-shaped slots 4 are evenly distributed along the circumference on the cylindrical surface of the grinding shoe body 1, and T-shaped cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com