High-efficiency sterilization, disinfection and cleaning device for dentures

A technology of sterilization and cleaning device, which is applied in the field of denture processing, which can solve the problems of laborious cleaning, reduction of denture strength, tooth cracks or micro cracks on the surface, etc., and achieve high-quality cleaning and disinfection operations, high efficiency and cleaning effect, and high-quality cleaning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

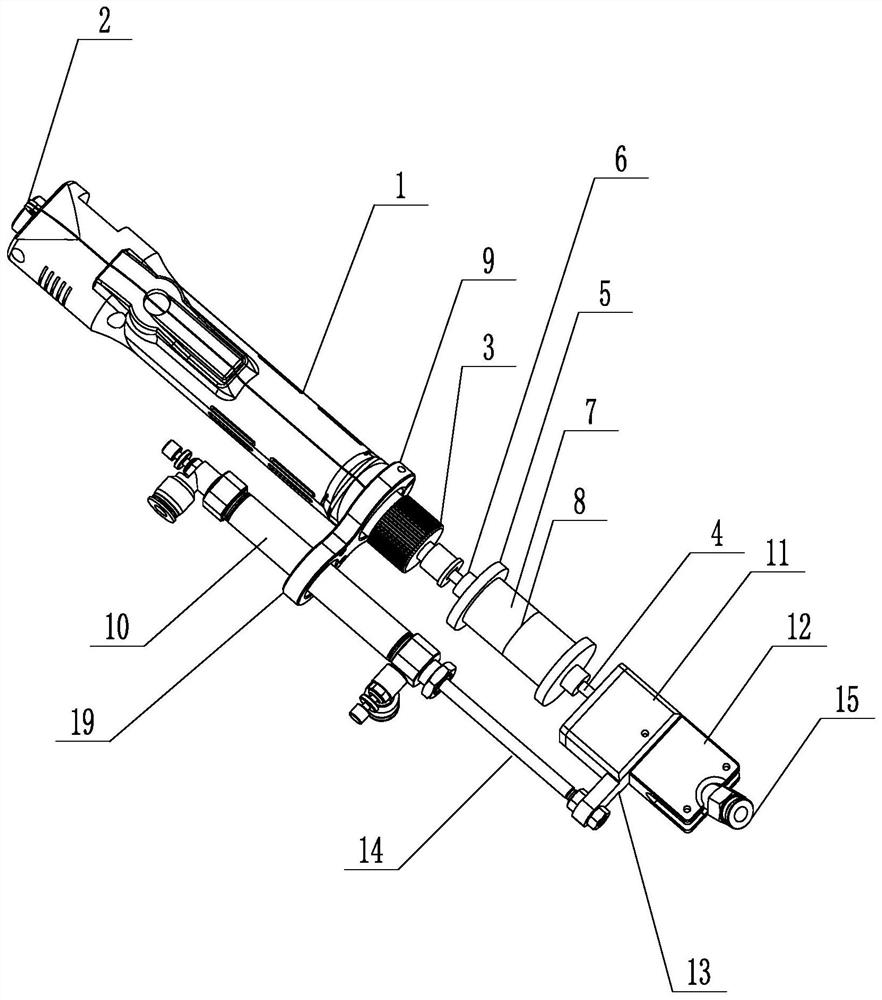

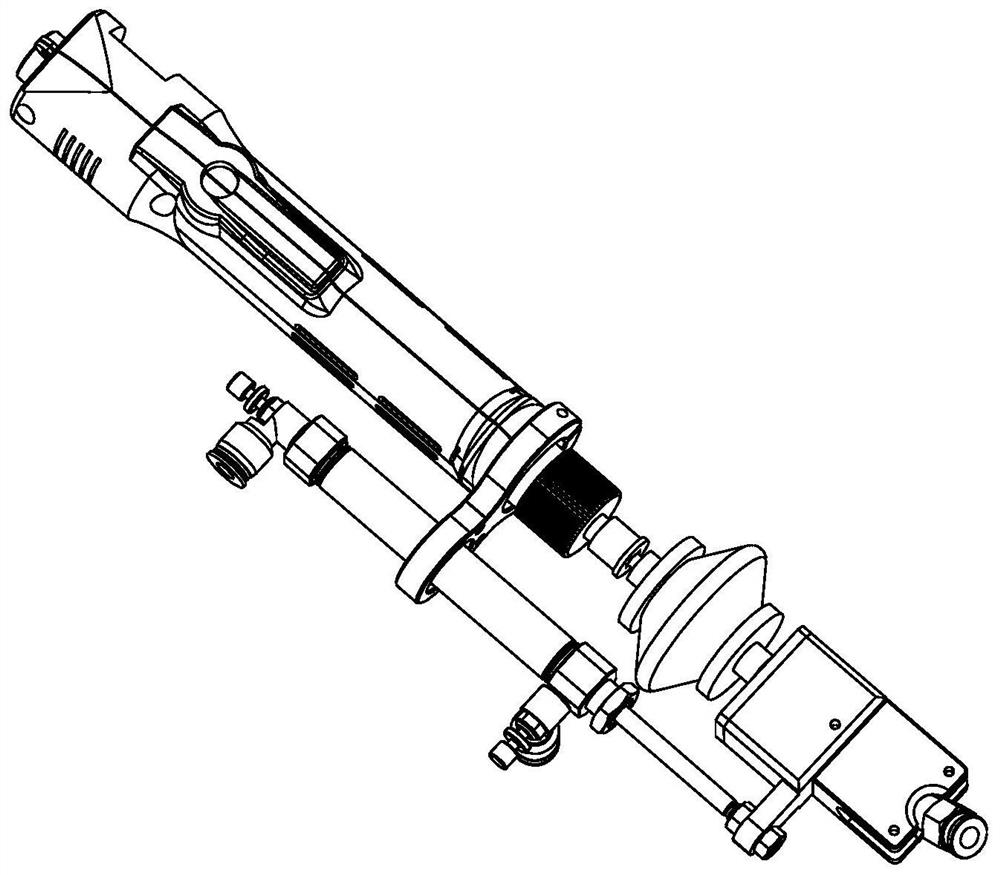

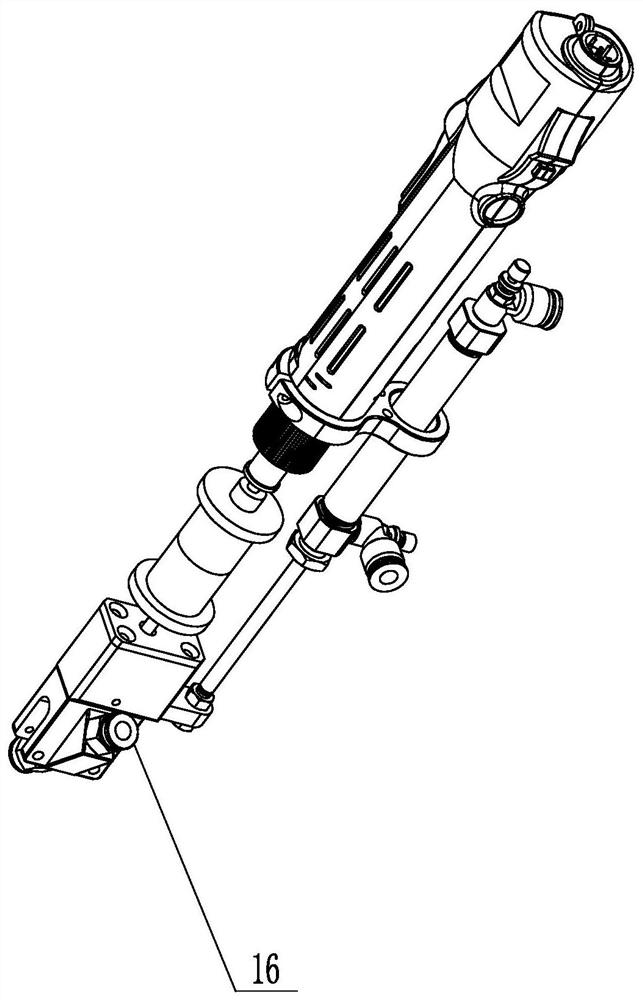

[0028] Example: A high-efficiency sterilization and cleaning device for dentures

[0029] This device is mainly a hand-held cleaning and disinfection all-in-one machine, including a pen-shaped straight body 1, and the rear end of the body 1 is provided with a power interface 2, which is used to connect with a wire to provide electric energy for the body 1, or Charges the internal rechargeable battery.

[0030] A rechargeable battery and a rotating motor are installed in the body 1, and the rechargeable battery is connected to the power interface 2 circuit, and the rechargeable battery can provide the body 1 to maintain the working state when it is inconvenient to plug in. If the workload is large and combined with functions such as cleaning and flushing, it is recommended to use it with electricity.

[0031] The bottom end of the fuselage 1 is provided with a machine head 3, and the bottom end of the machine head 3 is provided with a rotating shaft 4 that rotates with it. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com