Friction clutches for motor vehicles and corresponding motor vehicles

A technology for friction clutches and motor vehicles, which is applied in the field of motor vehicles and air gap devices for friction disc clutches, can solve the problems that the air gap function can no longer be completely ensured, and achieve the goal of avoiding the reduction of the friction surface and avoiding the damage of the friction surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

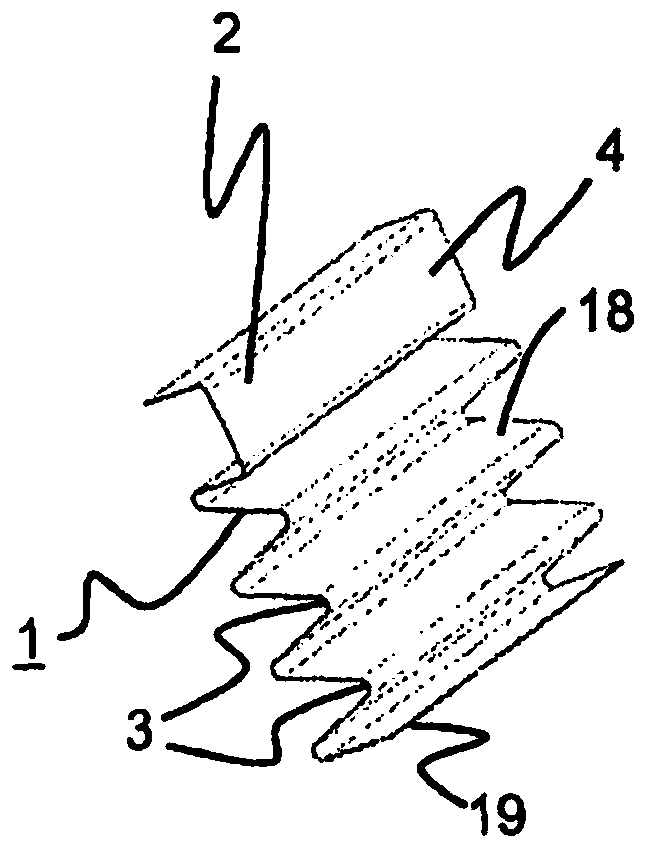

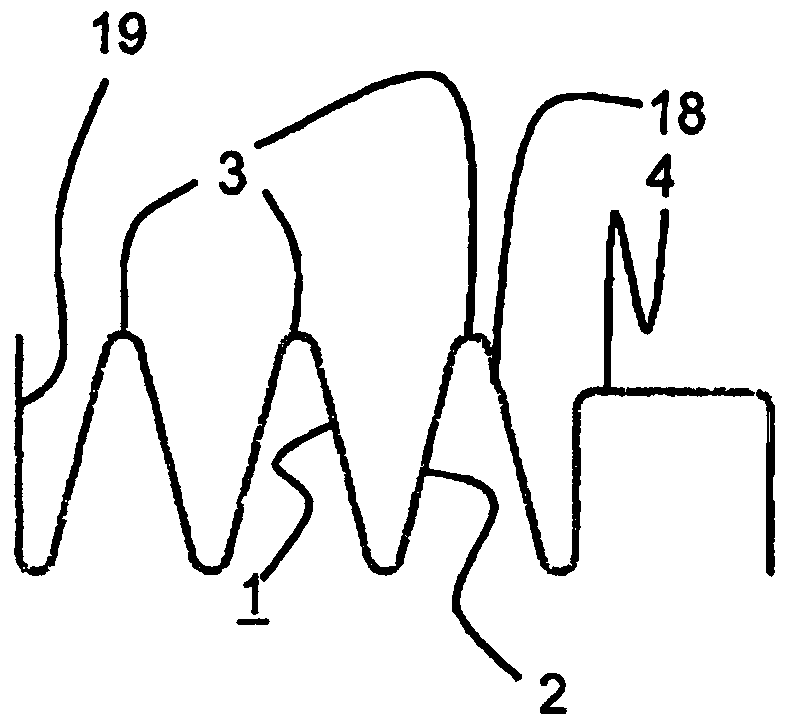

[0039] figure 1 and 2 A schematic view and a sectional view of the compression spring-like element 1 are shown schematically. The compression spring-like element 1 consists of a thin plate 2 . Sheet metal 2 is in particular a sheet metal made of spring steel. The compression spring-like element 1 is here produced by shaping the sheet metal 2 , wherein a plurality of folds 18 and thus inflection points 3 are formed, which are not completely assigned reference numerals for reasons of clarity. The compression spring-like element 1 has a contour with at least one inflection point 3 . In this case, inflection point 3 is to be understood as the point at which the contour of the compression spring-like element 1 changes its curvature, ie transitions from a "right turn" to a "left turn" or from a "left turn" Transition to "Right Turn". Furthermore, the compression spring-like element 1 also includes a connecting region 4 for a form-locking connection with a corresponding contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com