Air compressor clutch

A technology for air compressors and clutches, applied to clutches, non-mechanical drive clutches, magnetic drive clutches, etc., to achieve the effects of improving compressor life, reducing development costs, and improving vibration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

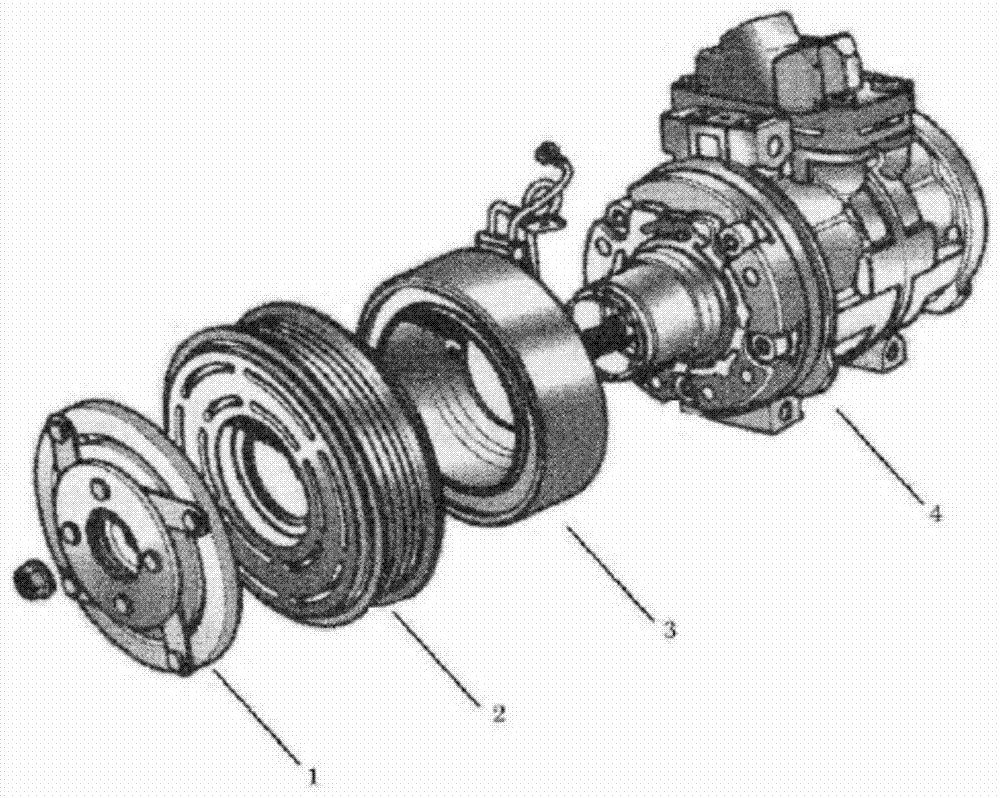

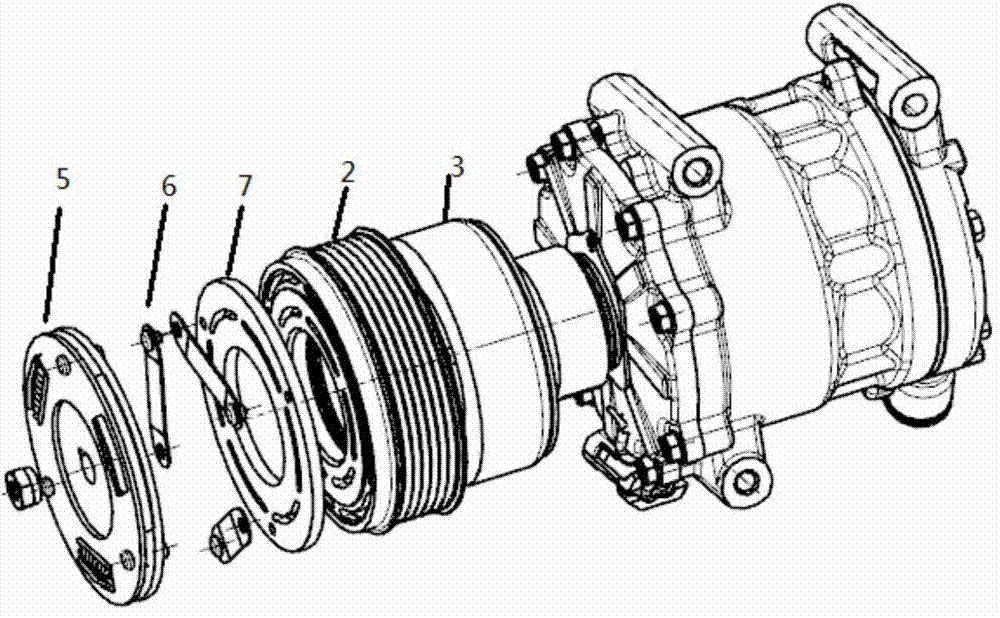

[0033] figure 2 It is a schematic diagram of an air compressor with an improved structure according to Embodiment 1 of the present invention. It is mainly composed of a driven plate 5, a leaf spring 6, a pressure plate 7, a belt pulley 2, an electromagnetic coil 3 and a compressor cylinder. The driven plate 5 , a leaf spring 6, a pressure plate 7, a belt pulley 2, and an electromagnetic coil 3 are sequentially connected along the direction of the main axis of the compressor, wherein the connection installation of the electromagnetic coil 3 and the belt pulley 2 is the same as that of a traditional compressor.

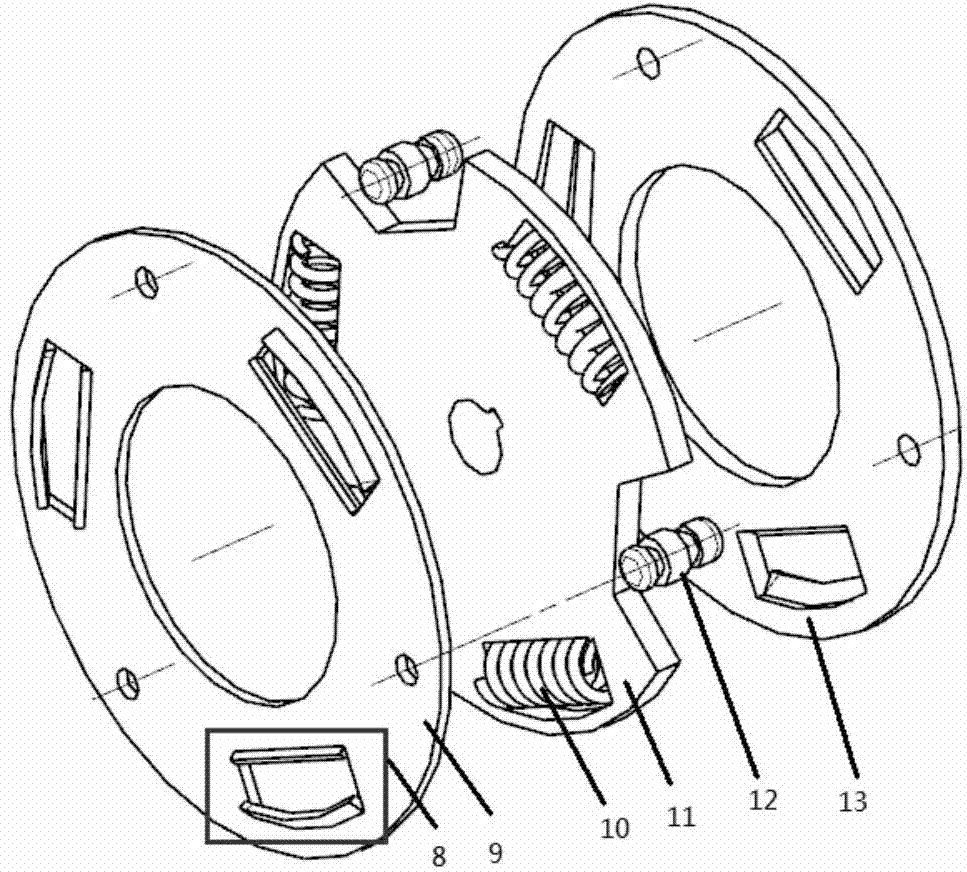

[0034] image 3 for figure 2 The structural schematic diagram of the driven disc 5 in , it can be seen that the driven disc 5 is composed of two driven outer plates 9 and 13, an inner plate 11, a coil spring 10 and a limit rivet 12, wherein the inner plate 11 The central hole is connected with the main shaft of the compressor through a key; the coil springs 10 are r...

Embodiment 2

[0039] Image 6 It is a schematic diagram of an air compressor with an improved structure according to Embodiment 2 of the present invention. The system device is mainly composed of a return spring 16, a driven plate 17, a belt pulley 2, an electromagnetic coil 3 and a compressor cylinder. The return spring 16 , the driven disk 17, the belt pulley 2, and the electromagnetic coil 3 are sequentially connected along the direction of the main shaft of the compressor, wherein the connecting installation mode of the electromagnetic coil 3 and the belt pulley 2 is basically the same as that of a traditional compressor.

[0040] Figure 7 It is a schematic diagram of the driven disc 17 according to Embodiment 2 of the present invention, which is mainly composed of a driven disc outer plate 9 , a coil spring 10 , an inner plate 11 , rivets 18 and a driven disc pressing plate 19 . The inner plate 11 is connected to the main shaft of the compressor through a connection key, the coil spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com