gate

A gate valve and valve body technology, applied in the field of valves, can solve the problems of insufficient stability of the valve stem, discounted sealing effect, poor sealing effect, etc., and achieve the effect of stable movement, not easy to fall off, and reduce the probability of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

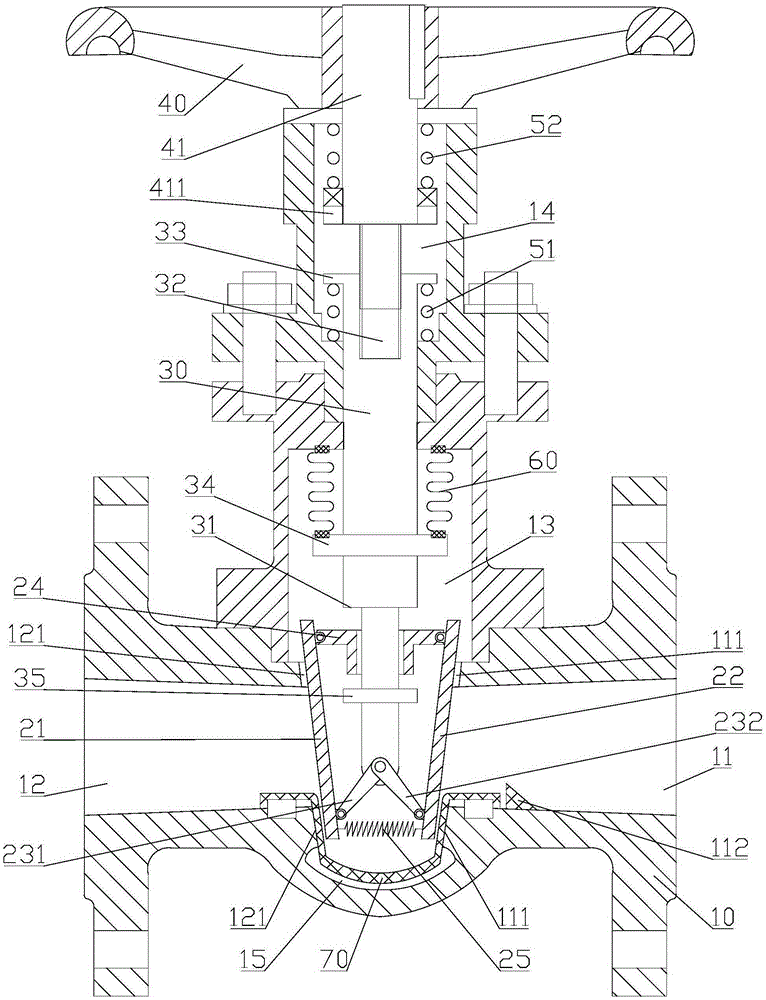

[0017] Examples, see figure 1 Shown: a gate valve, including a valve body 10, the lower part of the valve body 10 has a feed port 11 and a discharge port 12, and the left end face of the feed port 11 has a right sealing slope 111, and the right end face of the discharge port 12 has a The left sealing inclined surface 121 , a matching cavity 15 is provided between the lower part of the left sealing inclined surface 121 and the lower part of the right sealing inclined surface 111 . Simultaneously, the gate valve includes gate plates matched with the left and right sealing slopes 121 and 111 on the left and right sides, and a valve stem 30 is connected to the gate plate, and a handle 40 is arranged above the valve stem 30 . Apparently, the matching cavity 15 is used to make the lower part of the gate have an accommodation space when the gate is translated downwards and then sealed with the sealing slope.

[0018] Further speaking:

[0019] The shutter includes a left plate body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com