Internally-adjusted constant-micro-resistance check valve

A technology of check valve and micro-resistance, which is applied in the direction of control valve, valve device, function valve type, etc., and can solve the problems of energy consumption, low energy consumption, and small pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

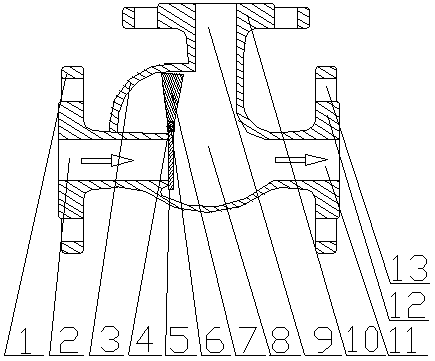

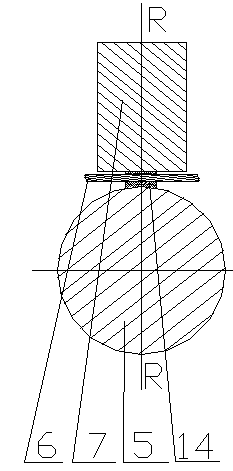

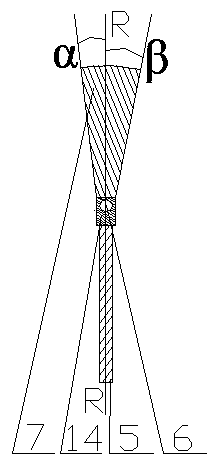

[0034] exist figure 1 In the embodiment of the horizontally installed check valve shown in —16: the internal adjustment type constant micro-resistance check valve includes a valve plate rotating shaft 6 and a valve plate connection block 14 connected and installed in the valve body 3 to be able to connect with the valve plate inlet The sealing ring 4 seals and rotates in the valve body 3 to open and close the valve plate 5, and the valve plate counterweight balance device connected to the side of the valve plate connection block 14 away from the valve plate 5, the valve plate counterweight balance device and the valve plate The center of the valve plate connecting block 14 between 5 is the valve plate rotating shaft 6; it is characterized in that: the valve plate counterweight balance device of the horizontally installed check valve has five structures: the valve plate counterweight balance device has five vertical valve plates The cross-section of the valve plate is an asymme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com