Brake control device for a brake system of a rail vehicle, brake system, rail vehicle and method for operating a brake control device

A technology of braking control and braking equipment, which is applied to the operating mechanism of the railway vehicle brake, the braking transmission device, the brake, etc., can solve the problem that the railway vehicle cannot be used for operation, and achieve the effect of optimizing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

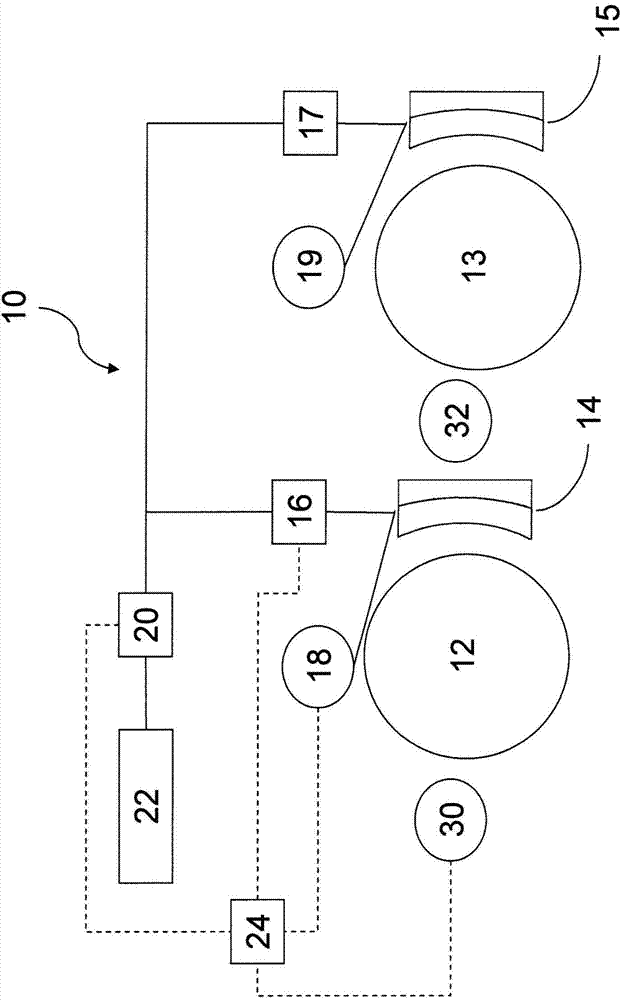

[0020] figure 1 A braking system 10 of a rail vehicle is shown schematically. Mechanical and pneumatic connections and lines are shown by solid lines, while electrical connections or communication channels are shown by dashed lines. For reasons of clarity, the electrical control lines for the components associated with the second vehicle are not shown. Of course, it is analogous to the control lines associated with the first wheel and the components of this wheel. The braking system 10 is provided for braking wheels 12 and 13 of a rail vehicle. In this example it is provided that the wheels 12 and 13 are located on different axles. The first brake pad 14 is assigned to the first wheel 12 . The second brake shoe 15 is assigned to the second wheel 13 . Each of the brake shoes 14, 15 has a brake lining which when the brake shoe 14, 15 with the brake lining is pressed onto the working surface of the corresponding wheel 12, 13, the brake lining The corresponding wheels 12, 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com