Device and method for reducing heat stress in poultry transportation in summer

A technology for heat stress and meat poultry, which is applied in the field of heat stress-resistant devices and devices for reducing heat stress in summer transportation of meat and poultry, which can solve the problem of unsatisfactory ventilation and cooling effects, inability to effectively relieve heat stress, Inability to effectively cool down and other problems, to achieve the effect of improving water loss, reducing heat stress, and improving meat quality and softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

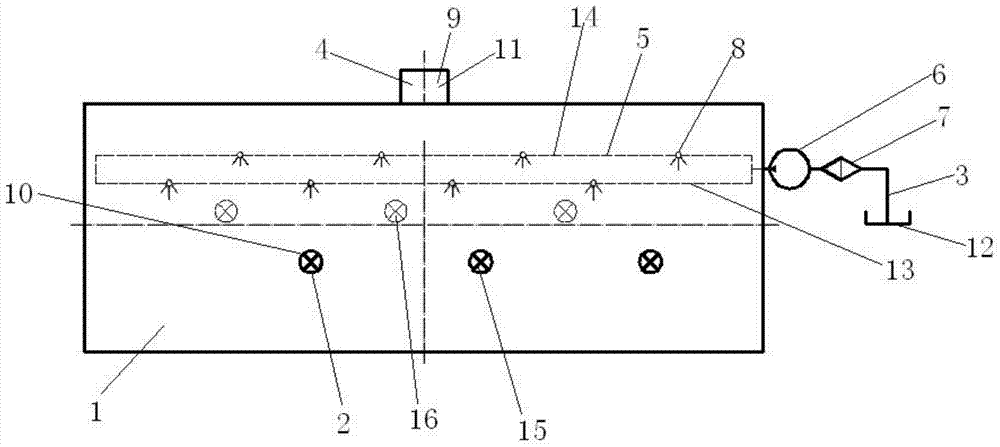

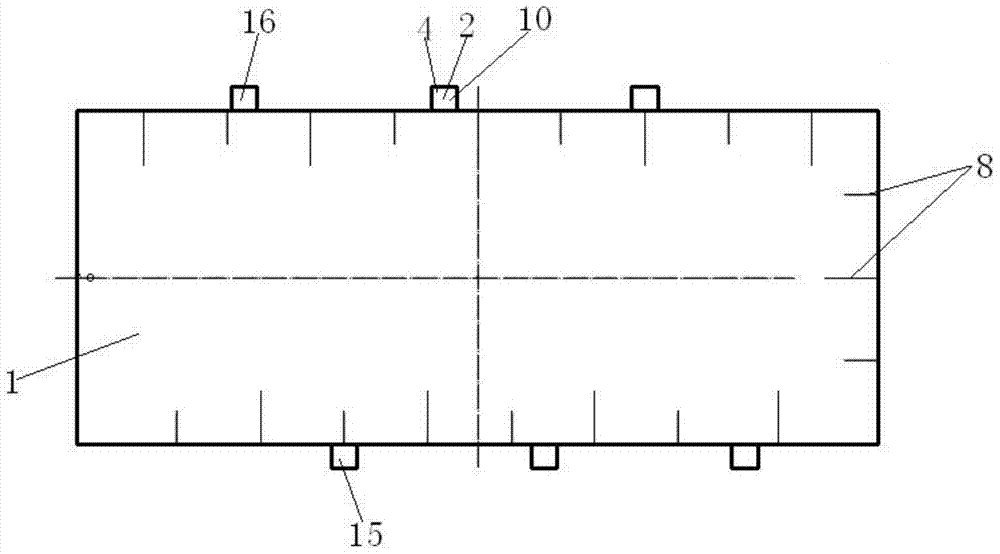

[0034] Such as Figure 1~2 Shown, a device for reducing heat stress during transport of meat and poultry in summer, characterized in that it includes a cooling room 1 and a cooling device 2;

[0035] The cooling device 2 includes a water supply unit 3, a spray-ventilation unit 4 and a circuit unit;

[0036] The water supply unit 3 includes a submersible pump 12, a water pipe 5, a high-pressure pump 6 and a filter 7;

[0037] Described shower-ventilation unit 4 comprises several shower nozzles 8 and fan 9;

[0038] The fan 9 includes an exhaust fan 11 and several axial flow fans 10;

[0039] The circuit unit includes a distribution box and electric wires;

[0040]The cooling room 1 includes two sides of the side wall, a rear wall, a roof and a rolling door for replacing the front wall; the axial flow fan 10 is installed on the two side walls, and the exhaust fan 11 is installed on the roof; The water outlet of the submersible pump 12 is connected to the water inlet of the f...

Embodiment 2

[0055] Such as Figure 1~2 Show, a kind of device that reduces the meat poultry transport heat stress in summer, the content is the same as the content of the device part in embodiment 1.

[0056] A method for reducing heat stress during transportation of meat and poultry in summer, characterized in that: comprising the following steps:

[0057] Step 1: Open the shutter door, reverse the truck full of caged broilers into the cooling room 1, and close the shutter door;

[0058] Step 2: Turn on the exhaust fan 11, the axial flow fan 10 and the nozzle 8, and perform the spray-ventilation operation. The spray-ventilation time is 8 minutes. After the spray-ventilation operation is completed, turn off the exhaust fan 11, the axial flow fan 10 and the nozzle 8;

[0059] Step 3: Open the shutter door again, drive the truck out of the cooling room 1, and rest in an open hood out of sunlight. The rest time is 32 minutes, and the sum of the spray-ventilation time and the rest time is g...

Embodiment 3

[0062] Such as Figure 1~2 Show, a kind of device that reduces the meat poultry transport heat stress in summer, the content is the same as the content of the device part in embodiment 1.

[0063] A method for reducing heat stress during transportation of meat and poultry in summer, characterized in that: comprising the following steps:

[0064] Step 1: Open the shutter door, reverse the truck full of caged broilers into the cooling room 1, and close the shutter door;

[0065] Step 2: Turn on the exhaust fan 11, the axial flow fan 10 and the nozzle 8, and perform the spray-ventilation operation. The spray-ventilation time is 12 minutes. After the spray-ventilation operation is completed, turn off the exhaust fan 11, the axial flow fan 10 and the nozzle 8;

[0066] Step 3: Open the shutter door again, drive the truck out of the cooling room 1, rest in an open hood out of sunlight for 28 minutes, and ensure that the sum of the spray-ventilation time and the rest time is 40 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com