Pressure cooling process of segmented reinforcing type parts of hot forming steel plate, and pressing machine servo ejector rod devices

A segmented strengthening and hot forming technology, applied in the field of high-strength steel stamping, can solve problems such as complex structures, achieve uniform processing technology, improve product strength or elongation, and have simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

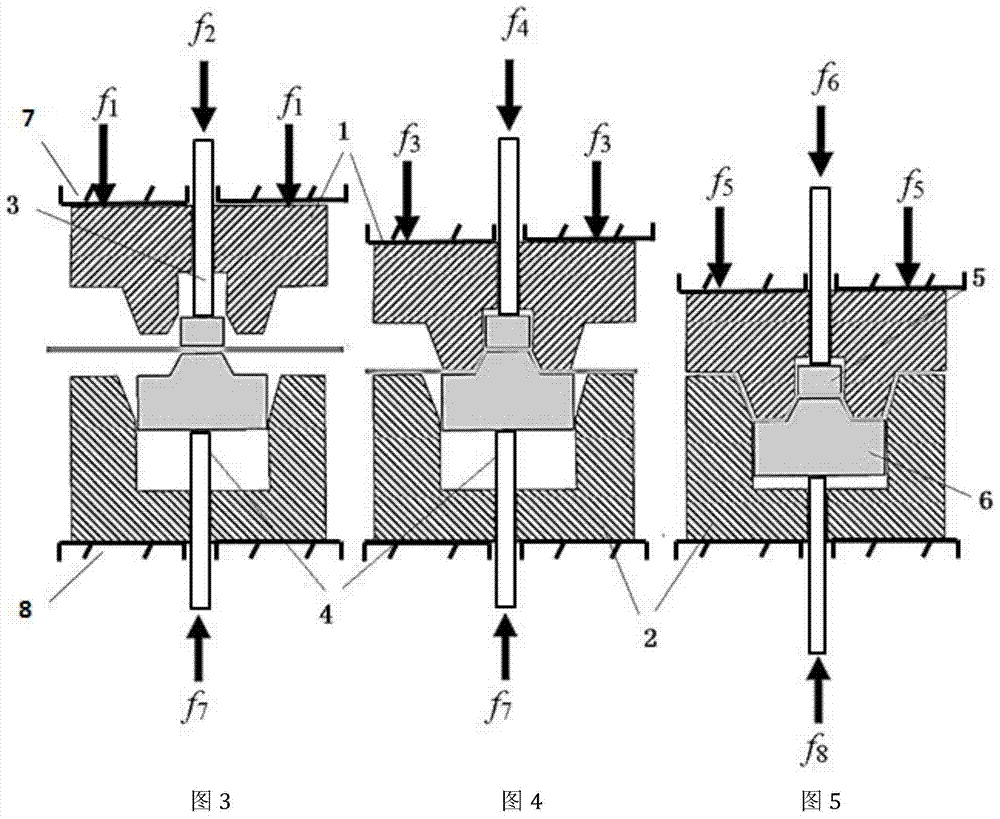

[0061] Such as Figure 3-Figure 5 As shown, the workpiece is 1.8mm thick, 150mm wide, and 1000mm long. The workpiece product requirement is f6 and the corresponding product area is HS400 soft area, and the rest are hard area HS1150. The concrete preparation process schematic diagram of this method, wherein:

[0062] figure 1 In its original state, according to figure 1 It can be seen that the device for realizing this method includes: upper mold 1, lower mold 2, upper servo ejector pin 3 of the press, lower servo ejector pin 4 of the press, upper mold pressing core 5, lower mold pressing core 6, upper workbench of the press ( Slider) 7, workbench 8 under the press.

[0063] The upper mold 1 covers the range of HS1150 in the hard area of the product, and the material is high-quality mold steel SKD61;

[0064] The upper mold pressing material core 5 covers the product soft zone HS400 range, and the material is high-quality mold steel SKD61;

[0065] The lower mold pressi...

Embodiment 2

[0076] Such as Figure 3-Figure 5 As shown, the workpiece is 1.8mm thick, 150mm wide, and 1000mm long. The product requirement of the workpiece is that the product area corresponding to f6 is HS400 soft area, f8 is soft area HS700 except for f6 area, and the rest areas of the product are hard area HS1150.

[0077] This method realizes the device such as figure 1 shown, where:

[0078] The upper mold 1 covers all areas of the product soft area HS700 and hard area HS1150, and the material is high-quality die steel SKD61;

[0079] The upper mold pressing material core 5 covers all areas of the soft area HS700 of the product, and the material is high-quality mold steel SKD61;

[0080] The lower mold pressing material core 6 covers all areas of the product soft zone HS400 and soft zone HS700, and the material is high-quality mold steel SKD61;

[0081] The lower mold 2 covers all areas of the hard area HS1150 of the product, and the material is high-quality mold steel SKD61;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com