Cold stamping drawing die

A drawing die and cold stamping technology, applied in the field of stamping die, to solve the problem of drawing balance and stability, reduce the size of the die, and stabilize the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

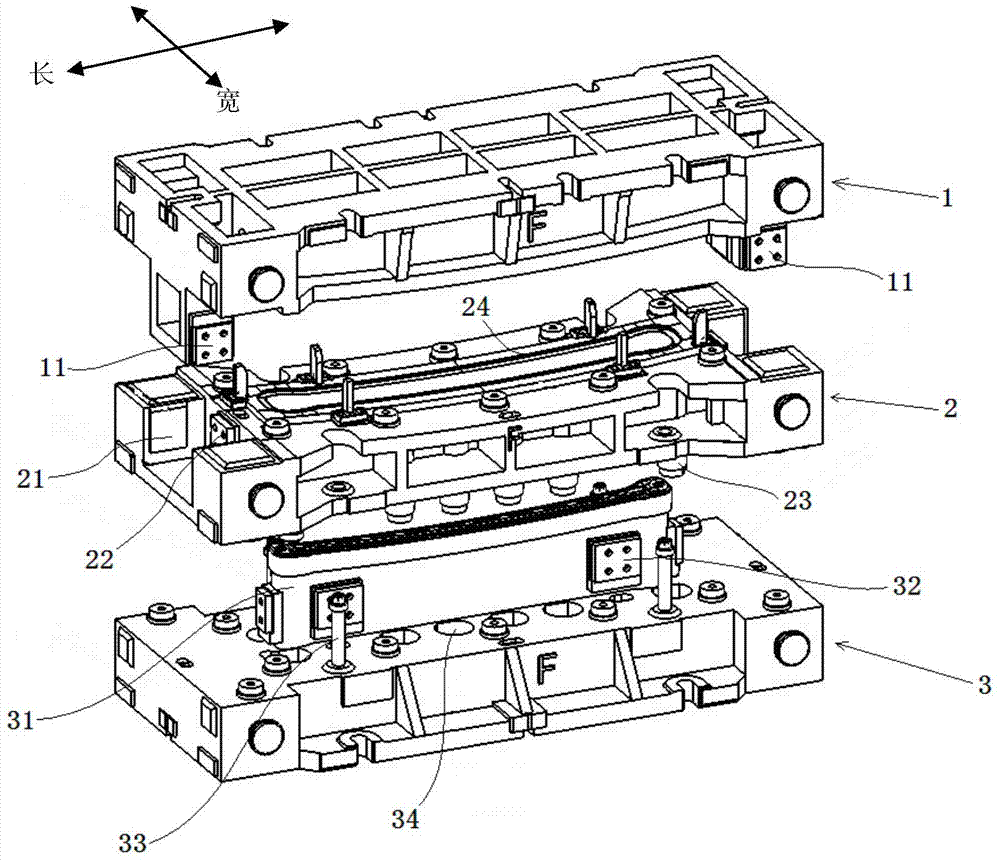

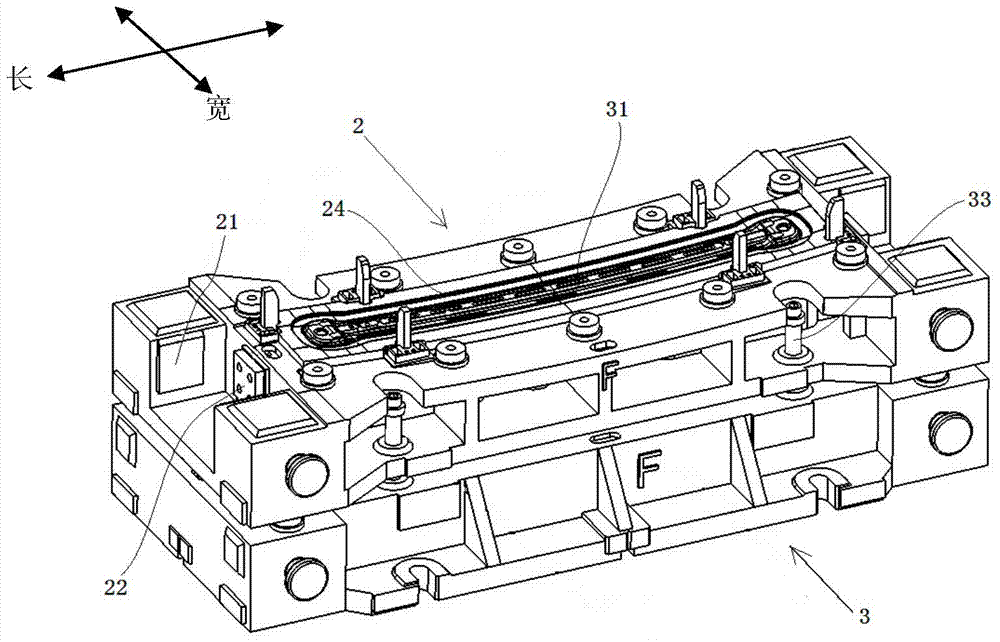

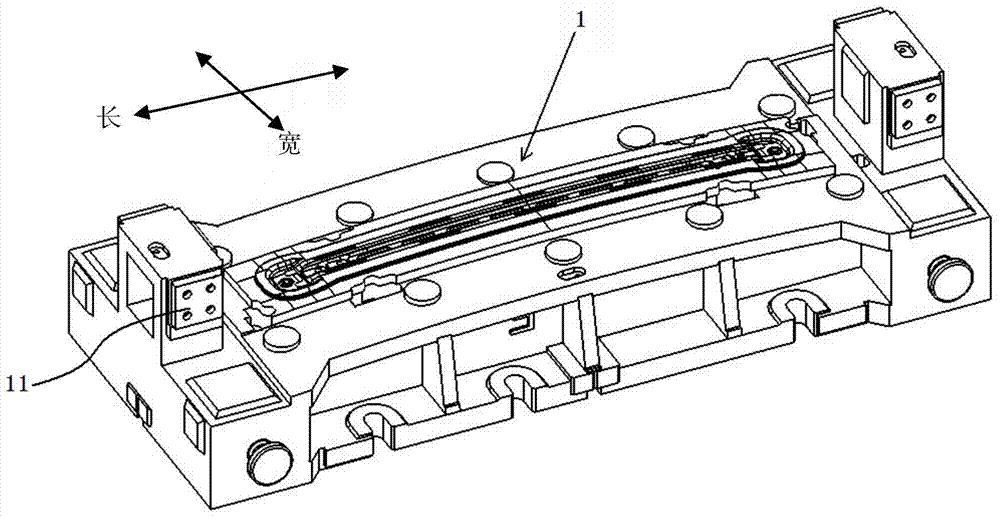

[0034] refer to Figure 5 , at this time the cold stamping drawing die is in the mold closing state. The lower mold base 3 is provided with a convex mold 31, and the convex mold 31 is either integrally cast with the lower mold base 3, or assembled together after being molded separately. combine Figure 5 , Figure 8 , Figure 9 and Figure 10 Visible, with Figure 1 to Figure 4 The difference of the prior art shown in is that in this embodiment, as the guide slide mechanism between the upper die base 1 and the blank holder 2, the upper die guide plate 11 on the upper die base 1 is changed from the original upper die The two ends in the length direction of the seat 1 are transferred to both sides in the width direction, and correspondingly, the guide sliding surface 21 on the blank holder 2 is also transferred to both sides in the width direction of the blank holder 2; at the same time, as In the guide-sliding mechanism between the blank holder 2 and the punch 31, blank h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com