A clamping and shearing device of an automatic tape winding machine and its working method

A technology of shearing device and clamping device, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of increasing production costs, increasing labor costs, and low production efficiency, so as to save production costs and save Labor costs and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

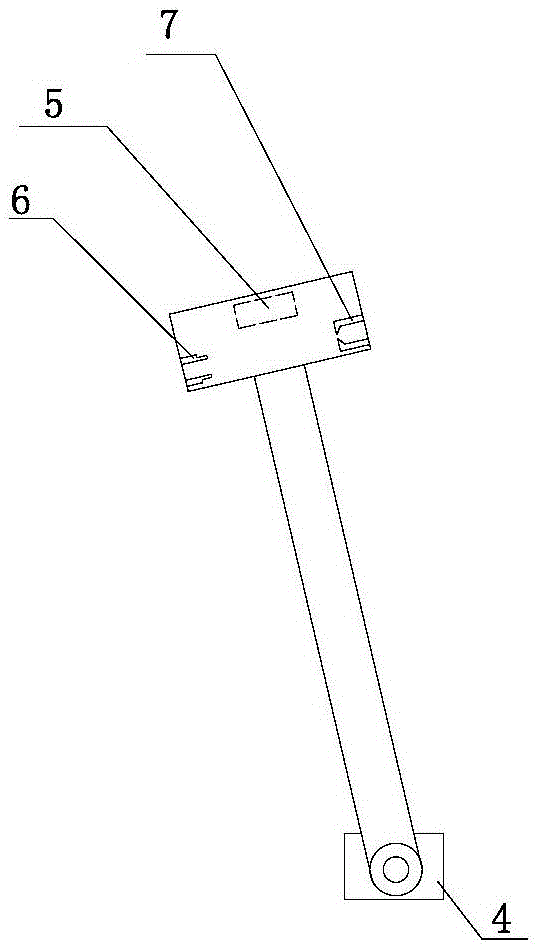

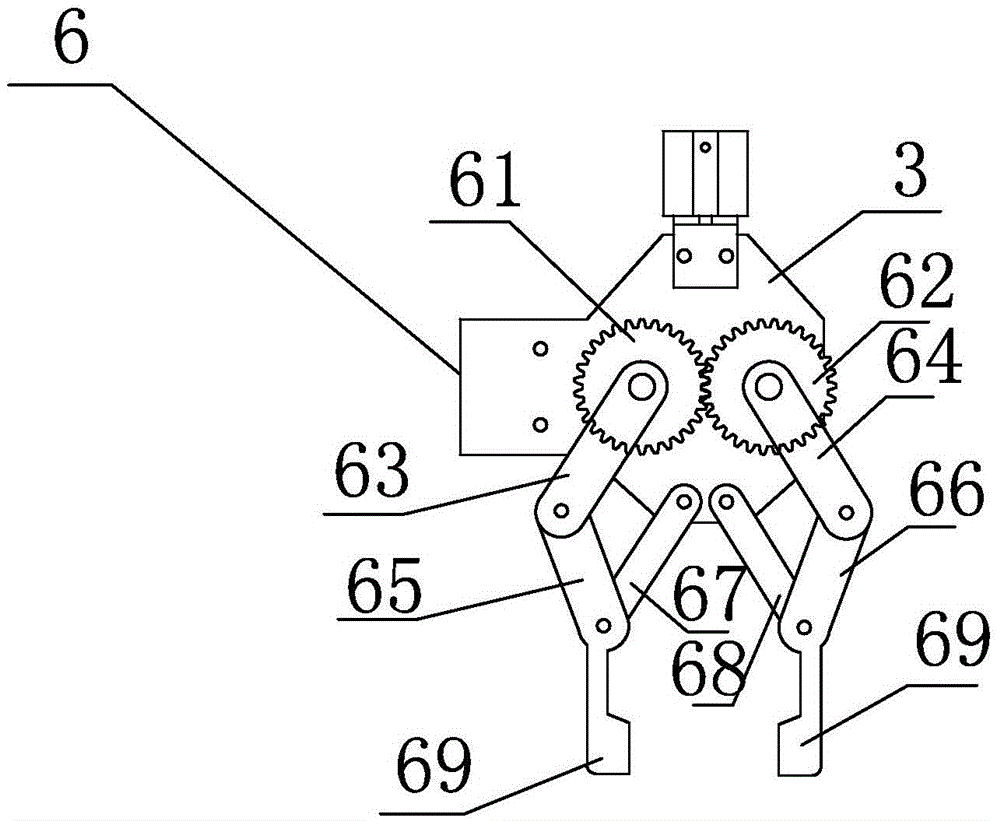

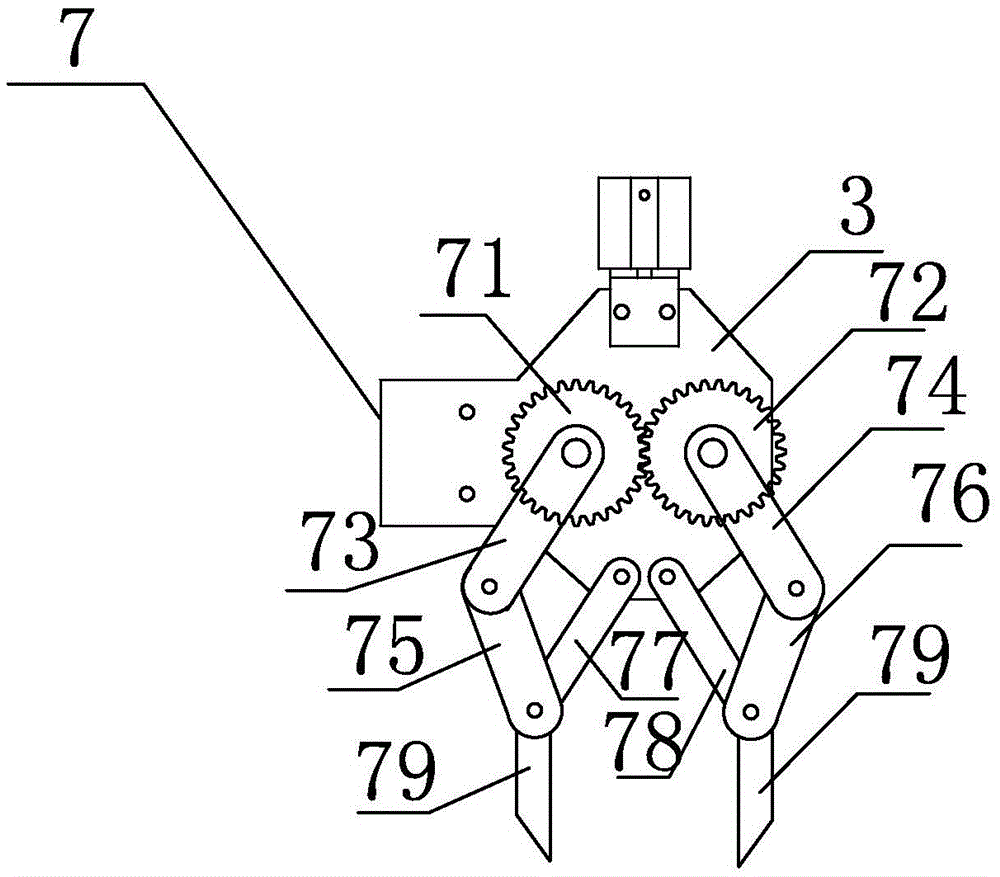

[0018] Such as figure 1 , 2 , Shown in 3, a kind of clamping and cutting device of automatic winding machine, comprises support 3; The first motor 5, clamping device 6 and shearing device 7 are installed on described support 3; Described clamping device 6 comprises The first gear 61 and the second gear 62 installed on the bracket 3, and the first gear 61 and the second gear 62 are meshed and installed; the first crank 63 is installed on the central axis of the first gear 61; A second crank 64 is installed on the central axis of the second gear 62; the first crank 63 is connected to the first rocker 67 that is movably installed on the bracket 3 through the first connecting rod 65; the second crank 64 is connected with the second rocker 68 that is movably installed on the bracket 3 through the second connecting rod 66; the first connecting rod 65 and the second connecting rod 66 are fixedly installed with clamping parts 69 respectively; The device 7 includes a third gear 71 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com