Preparation method and device for expanding hole at end of glass capillary

A glass capillary and capillary technology, used in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as difficulty in reaming, and achieve the effect of preventing weak bonding force of lubricating glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

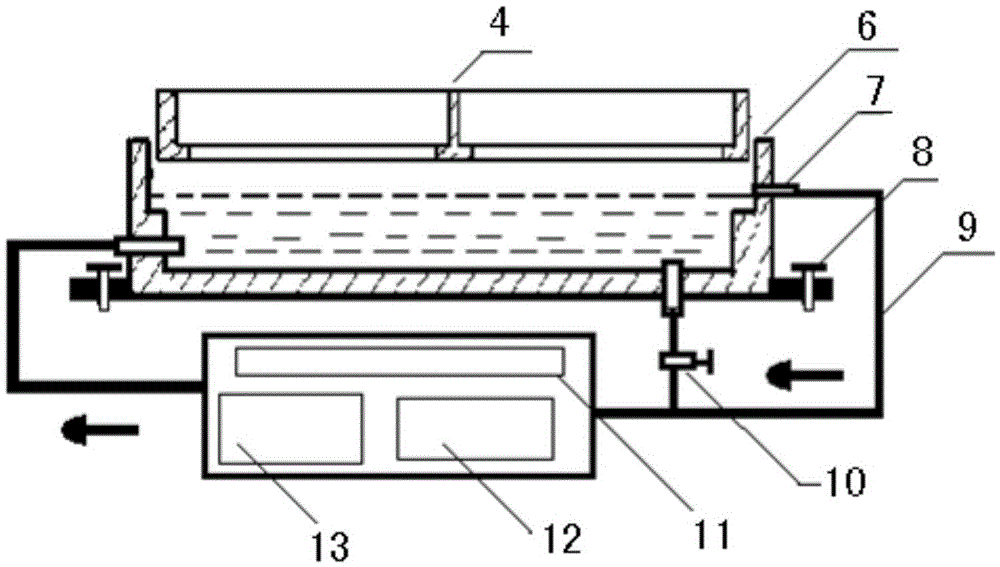

Method used

Image

Examples

Embodiment 1

[0023] Example 1: An example of preparing a single-ended borosilicate glass single-fiber capillary with a flared mouth by horizontally controlled height-directed etching

[0024] According to the method of the present invention, Table 1 lists the physical and chemical performance index and the geometric index after cutting of a typical high borosilicate quartz glass capillary.

[0025] Table 1 Performance index of high borosilicate glass capillary

[0026]

[0027]

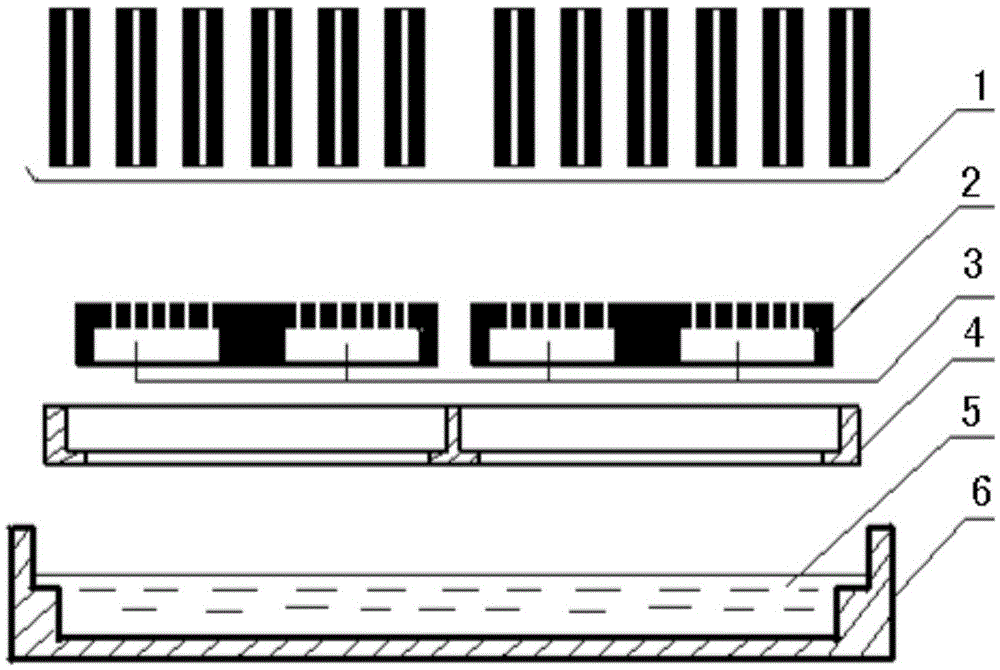

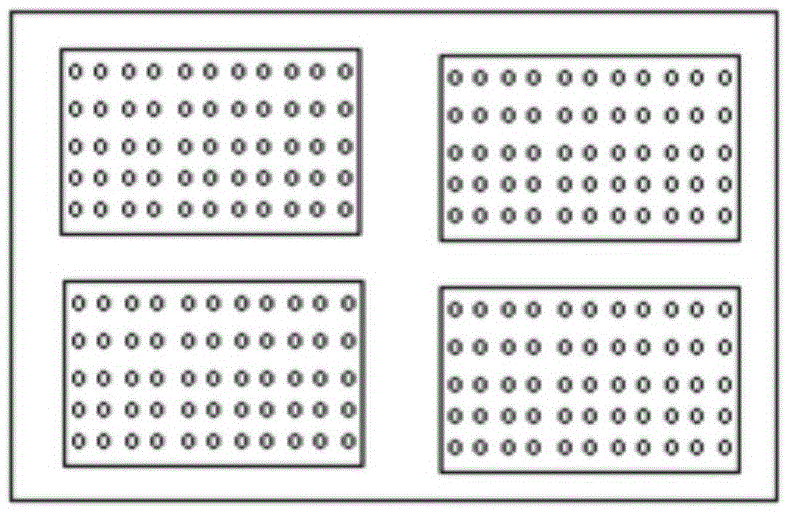

[0028] According to the method of the present invention, select as image 3 The abrasive tool 2 shown is for arraying glass capillaries and preparing inclusions. The specific operation method is as follows: fix the abrasive tool 2 used for the 1.0mm glass capillary 1 on the horizontal workbench, the inclusion cavity 3 is upward, arrange the above-mentioned glass capillary into the template in sequence, so that the lower cut surface of the glass capillary 1 is aligned with the The lower end of the abrasive ...

Embodiment 2

[0031] Example 2: Example of preparing double-ended quartz glass multifiber capillary tube with bell mouth by vertical immersion directional etching

[0032] According to the method of the present invention, the high-purity synthetic quartz racetrack-type multifibril capillary is selected as the glass capillary 1 of the present invention, and its key geometric indicators include: a length of 18.0 ± 0.1mm, an outer diameter of 2.190-2.205mm, an inner hole, etc. The effective single fiber diameter is 0.126-0.130mm.

[0033] Press the method of the present invention, select similar as image 3 The abrasive tool 2 with symmetrical double-sided encapsulation chambers is used to arrange glass capillaries in an array and prepare inclusions. The specific operation method is as follows: the grinding tool 2 used for the 2.2mm glass capillary 1 is fixed on the horizontal workbench. What is different from the first embodiment is that the grinding tool 2 has a double-sided wrapped cavity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com