Light steel roof truss with continuous structural beams

A technology of structural beams and light steel, which is applied in the field of light steel roof trusses, can solve the problems of inconvenient house construction and decoration, etc., achieve the effects of wide application range and occasions, enhanced structural strength, and enhanced pressure resistance and bending moment resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation and structure of the light steel roof truss provided with continuous structural beams according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail as follows.

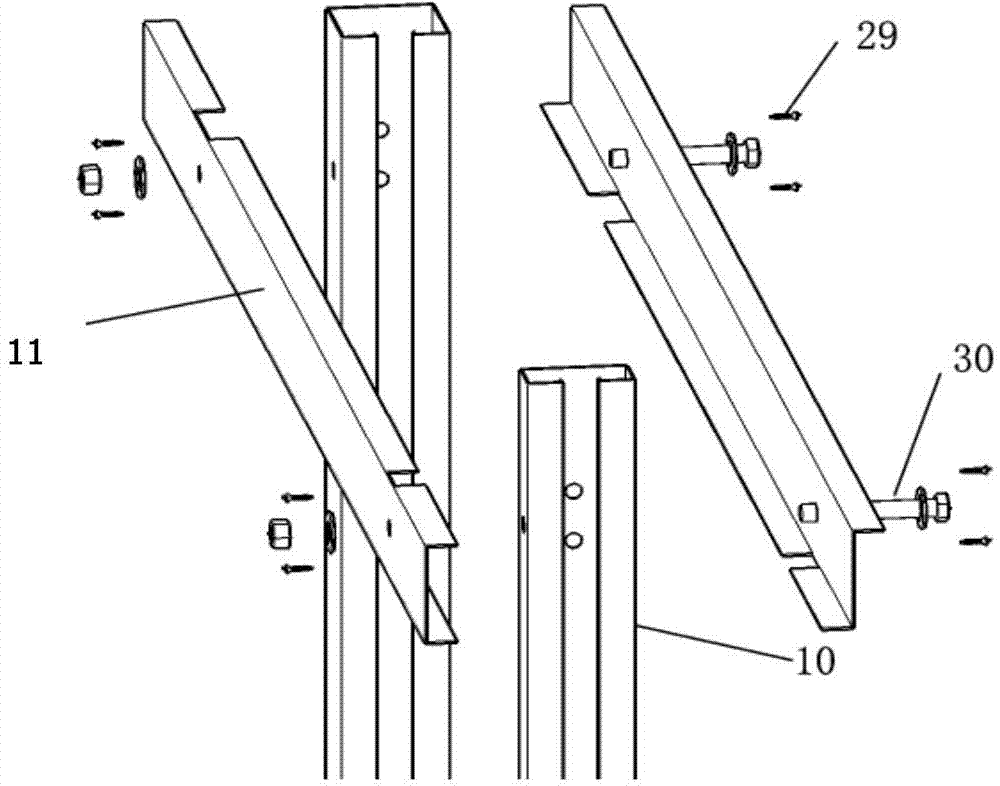

[0067] see figure 1 As shown, the upper and lower edges at the intersection of the embedded structural beam 11 and the structural column 10 are removed, and the structural beam and the structural column are fixedly connected by bolts 30 or self-tapping screws 29 . figure 1 The preferred fixed connection mode of the structural beam and the structural column in the present invention is shown.

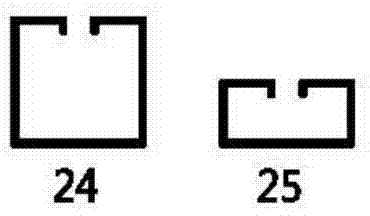

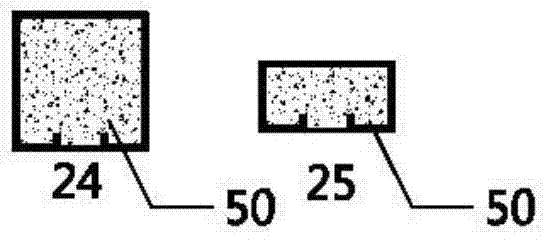

[0068] Figure 2A with 2B The cross-sectional schematic diagrams of rectangular or square structural columns and diagonal braces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com