A post-earthquake self-resetting concrete frame-central support structure system

A central support and concrete technology, applied in the direction of earthquake resistance, building components, etc., can solve problems such as cracks, joints that do not show ductile anti-seismic performance, and seam separation, so as to avoid environmental pollution, reduce repair difficulty and cost, and reduce construction waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

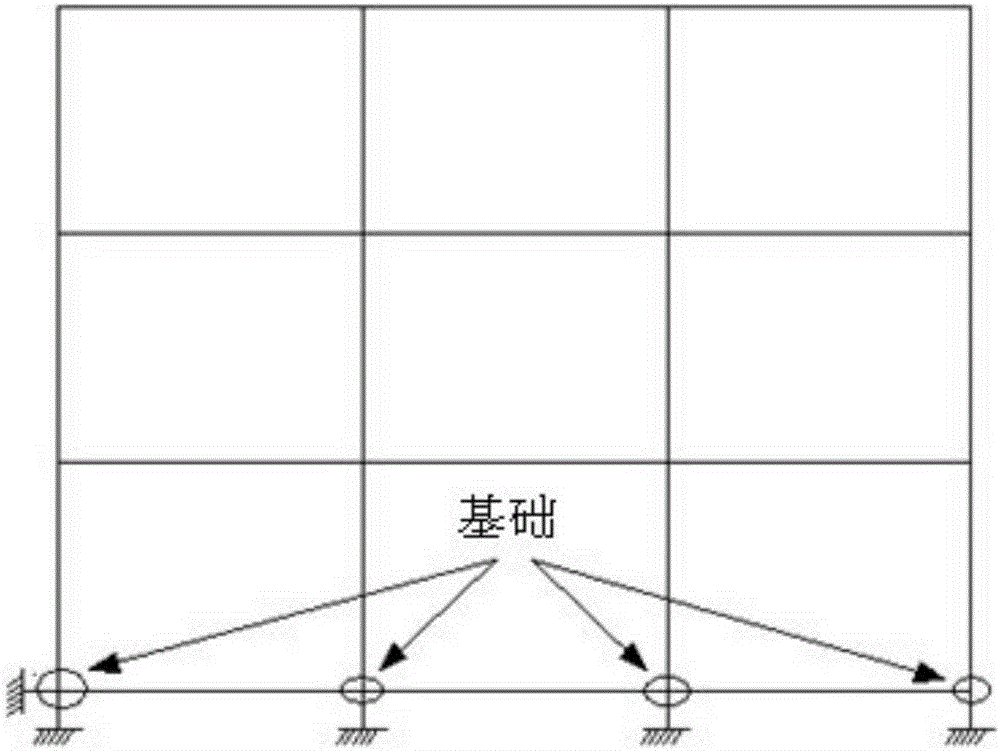

[0026] A post-earthquake self-resetting concrete frame-central support structure system includes a self-resetting concrete frame and a central support structure.

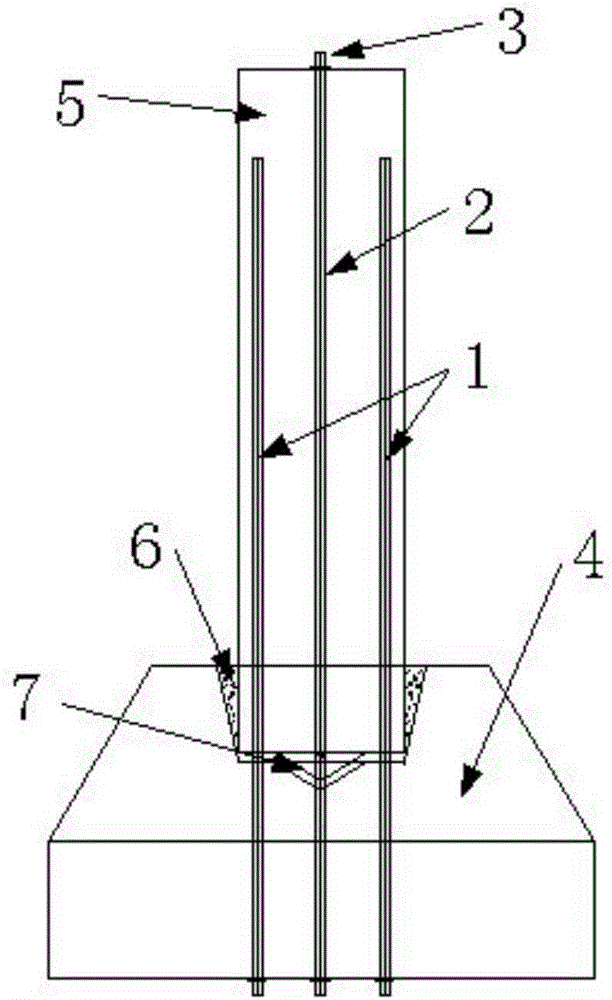

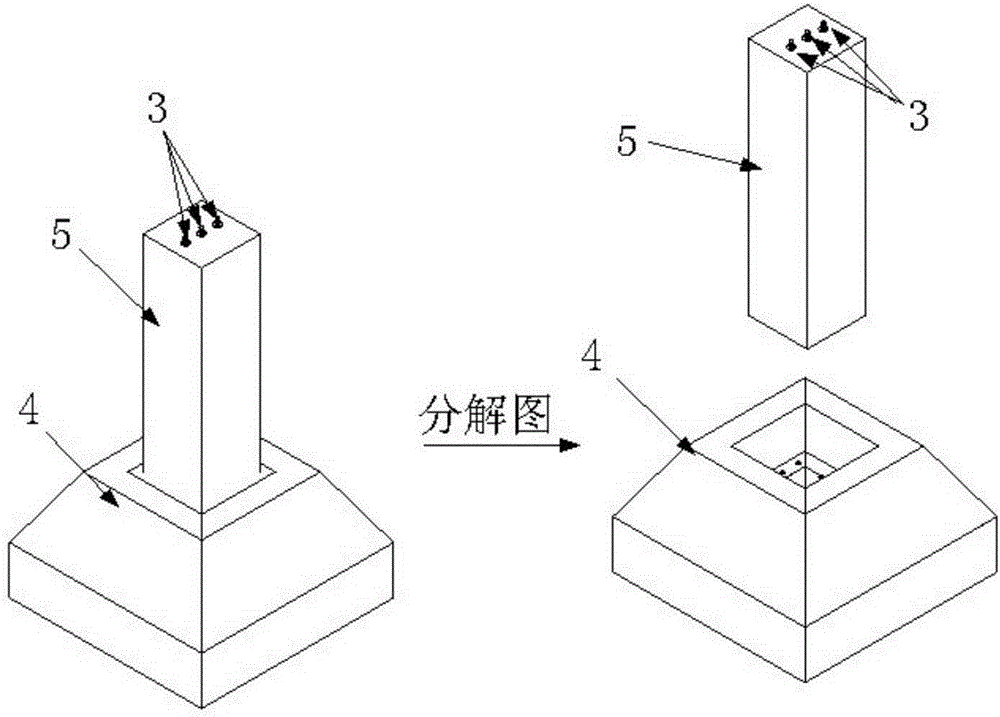

[0027] Such as Figure 1-6 As shown, the self-resetting concrete frame of this structural system includes a cup-shaped foundation 4 and a frame column 5; The groove step assembled on the surface, the middle of the groove step is provided with a tapered groove 10, and the two ends of the tapered groove 10 on the groove step plane are arranged side by side. The middle layer of the trough 10 is provided with cup-shaped foundation reserved prestressed steel holes 9 side by side; the cup-shaped foundation reserved energy-dissipating steel holes 8 and the cup-shaped foundation reserved prestressed steel holes 9 are parallel structures.

[0028] The frame column 5 is a cylindrical cone head structure, and one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com