Bending Stamping Die

A stamping die and bending technology, applied in the field of die, can solve the problems of low production efficiency, many bending operation procedures, and the production method cannot meet the needs, and achieve the effect of high production efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

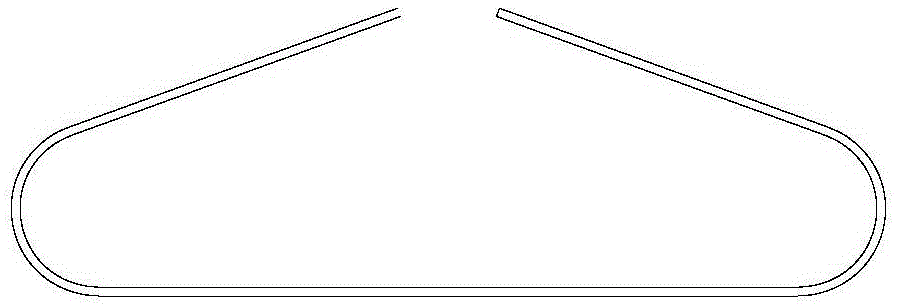

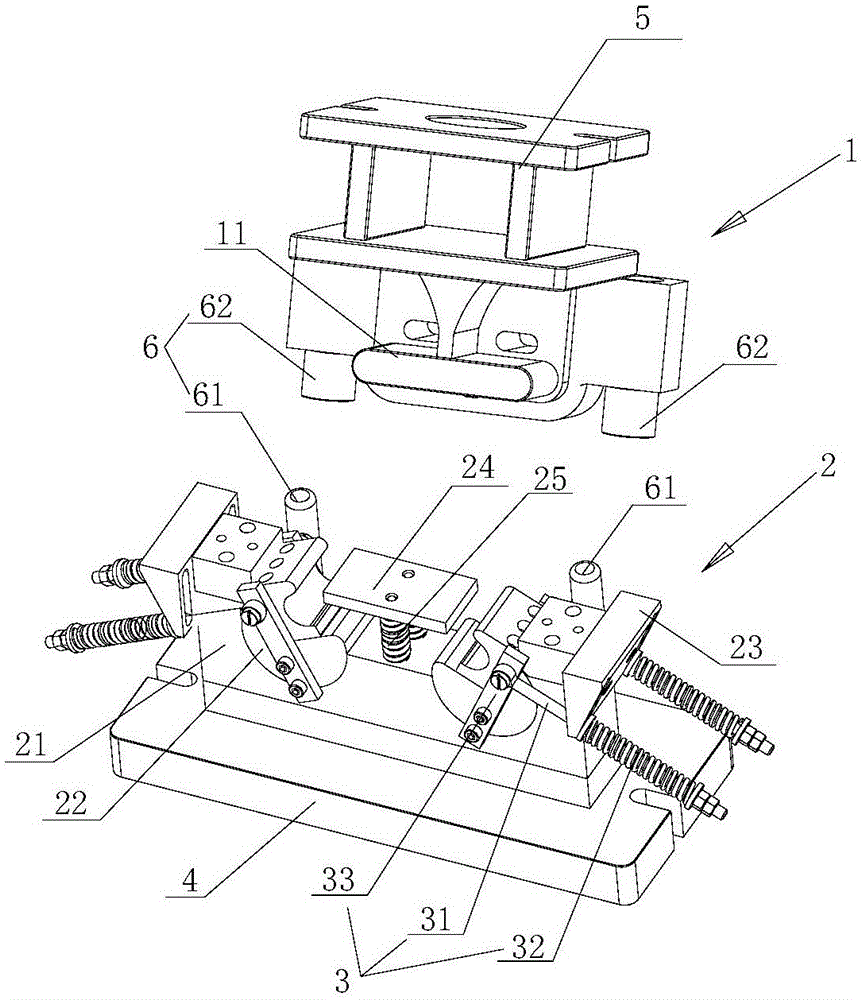

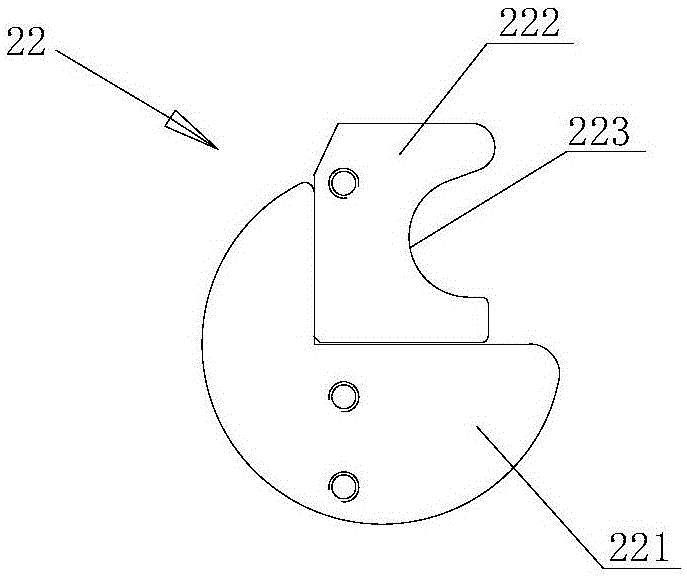

[0014] Embodiments of the present invention provide a bending stamping die, such as figure 2 and image 3 As shown, the bending stamping die includes a punch 1 and a die 2 corresponding to the punch 1, through the cooperation of the punch 1 and the die 2, the bending of the workpiece is completed; wherein the die 2 includes a die body 21 And the rotary block 22 embedded on the concave mold body 21 that can rotate relative to the concave mold body 21, the rotary block 22 is provided with the molding surface of the bending position of the workpiece; The punch 1 can push the rotary block 22 to rotate, and the forming surface of the rotary block 22 rotates and the die body 21 forms a cavity for bending and stamping the workpiece. At this time, the die body 11 of the punch 1 gradually enters the cavity of the die 2 In the model cavity, the state after the mating of the punch 1 and the die 2 is as follows: Figure 5 As shown, the workpiece in the concave mold cavity is stamped an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com