Drum brown paper automatic conveying and cutting device

A technology of automatic conveying and cutting device, applied in the directions of transportation and packaging, automatic control of packaging, packaging, etc., can solve the problems of slow packaging speed, complex process, poor flexibility, etc., to avoid waste, reduce costs, and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

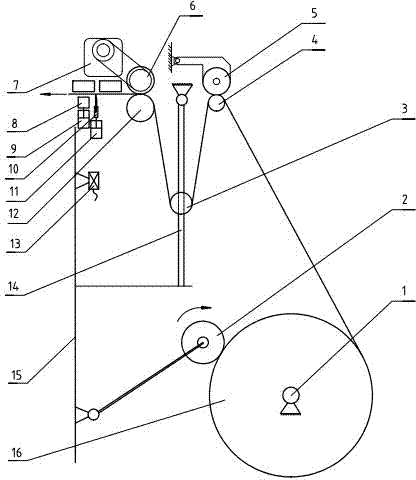

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

[0011] Such as figure 1 As shown, a roll kraft paper automatic conveying and cutting device includes a frame 15, a drive rubber wheel 2 and a reel 1 for placing a roll kraft paper 16 are arranged below the frame 15; Input roller 4, anti-curvature adjusting roller 3, output roller 6 and driven output roller 12; the top of the input roller 4 is provided with a width cutter 5; the anti-curvature adjusting roller 3 is located on the guide rod 14; A photoelectric sensor 13 is arranged on the opposite side of the anti-curvature adjusting roller 3; the output roller 6 is driven by a motor 7; A first air cylinder 11 is connected below the paper cutting knife 10 ; a second air cylinder 9 is connected below the paper pressing strip 8 . The motor 7 is provided with an encoder.

[0012] When working, the motor 7 drives the output roller 6 to output the kraft paper, and along wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com