Chip position calibration tool and calibration method, chemical vapor deposition reaction chamber

A chemical vapor deposition and reaction chamber technology, which is applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of inability to form a film layer on the chip, and the quality of the film layer is low, and achieves improved accuracy, The effect of reducing the failure rate and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

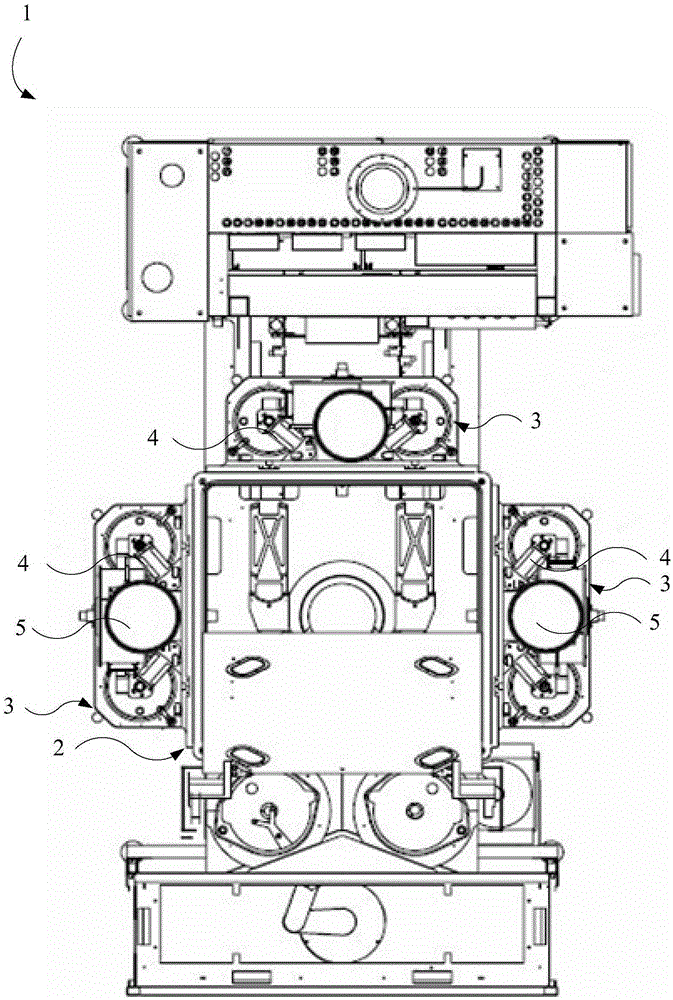

[0031] refer to figure 1 , the chemical vapor deposition equipment 1 includes a transfer chamber 2, a plurality of chemical vapor deposition reaction chambers 3 and a plurality of gate valves, and a plurality of chemical vapor deposition reaction chambers 3 are respectively located outside the transfer chamber 2, and all pass through the gate valve and transfer Chamber 2 communicates. combined reference figure 1 and figure 2 , the transfer of the chip 5 between the transfer chamber 2 and the chemical vapor deposition reaction chamber 3 is realized by the manipulator 4 .

[0032] combined reference Figure 1 to Figure 5 After the manipulator 4 transfers the chip 5 to the chemical vapor deposition reaction chamber 3 , the chip 5 needs to complete the film deposition operation on the heater (Heater) 32 in the chemical vapor deposition reaction chamber 3 .

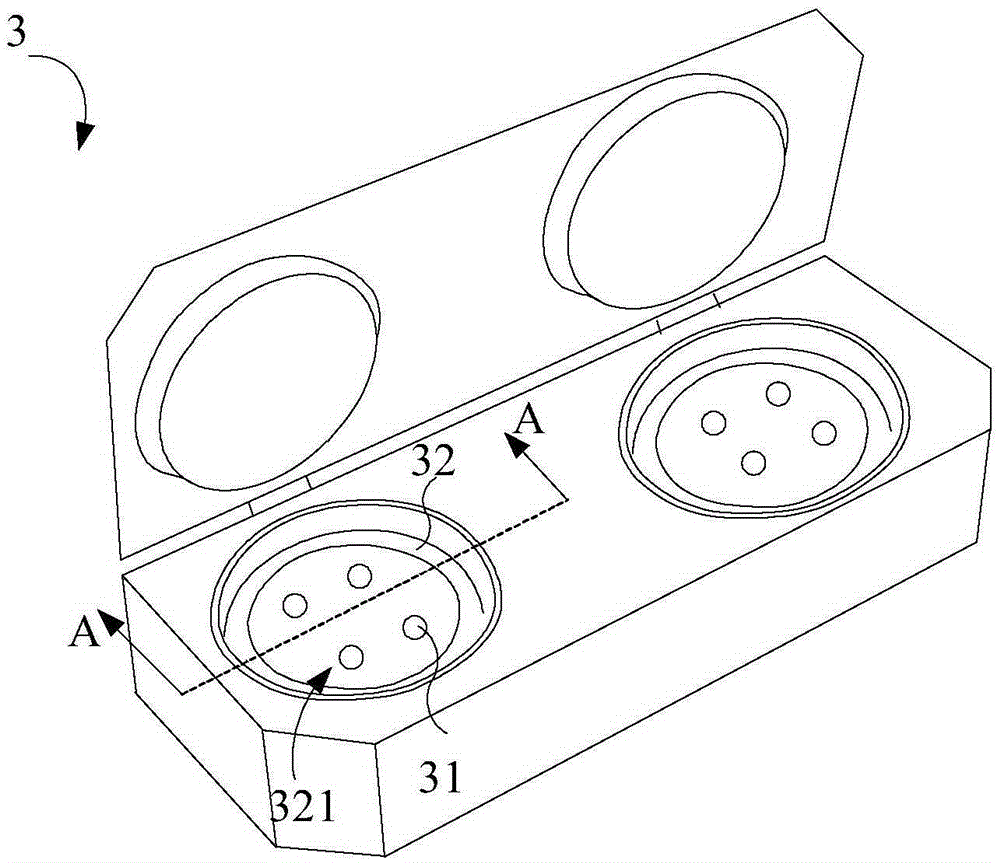

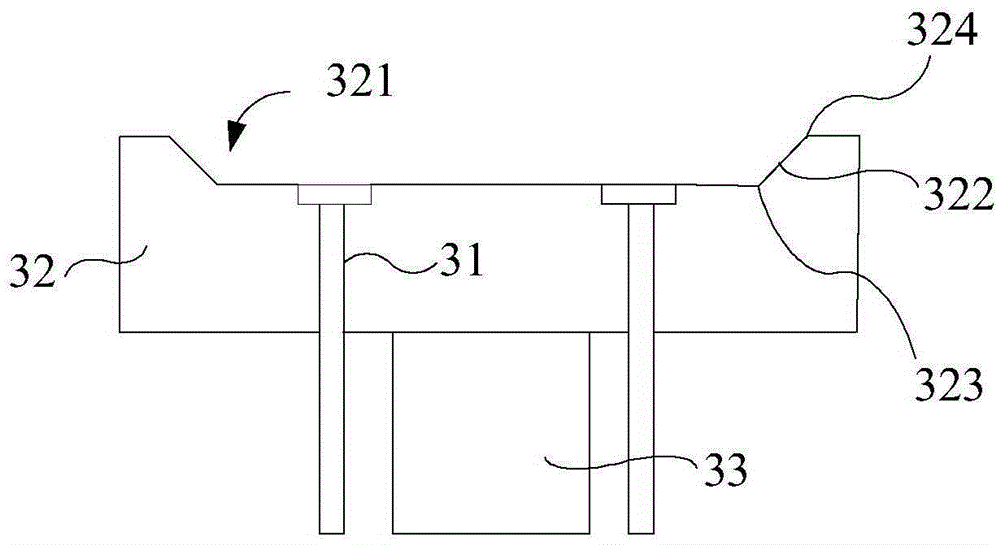

[0033] refer to figure 2 and image 3 , the heater 32 is a cylindrical structure, the top surface of the heater 32 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com