Steel arch assembling machine

A technology of steel arch frame and assembly machine, which is applied in the direction of pillars/brackets, mining equipment, earthwork drilling and mining, etc. It can solve the problems of slow splicing speed and cannot meet the requirements of tunnel boring machine's driving speed, so as to prevent vibration damage and be convenient and fast The effect of arch assembly and impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

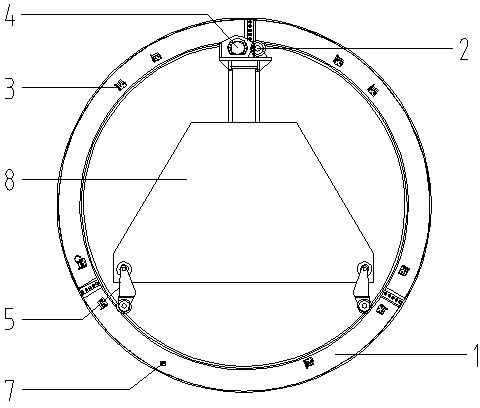

[0028] Such as figure 1 As shown, the steel arch assembling machine of this embodiment includes the main beam 8 of the roadheader, and three guide wheels are arranged on the main beam 8 of the roadheader, which are an upper guide wheel 2 and two lower guide wheels 5 respectively.

[0029] The upper guide wheel 2 is arranged directly above the main beam 8 of the roadheader, and a hydraulic motor 4 is arranged on the upper guide wheel 2, and the hydraulic motor 4 drives the ring beam 1 arranged outside the guide wheel to rotate through gear engagement. The guide wheel 2 is used to bear the weight of the ring beam and drive the ring beam to rotate.

[0030] The two lower guide wheels 5 are symmetrically arranged on the left and right sides of the main beam 8 of the roadheader with the longitudinal center line of the main beam 8 of the roadheader as the symmetrical axis, and are used to support the rotation of the ring beam 1. Orientation and radial positioning.

[0031] The who...

Embodiment 2

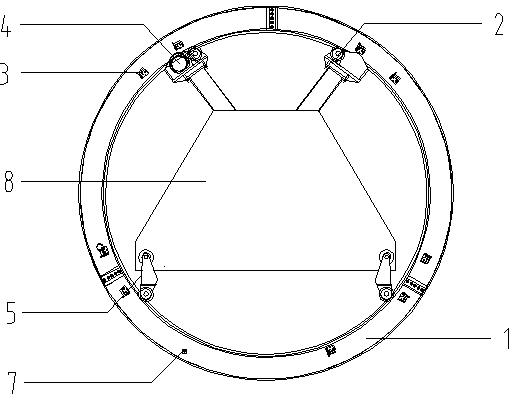

[0034] Such as figure 2 As shown, the structure of the steel arch assembly machine of this embodiment is basically the same as that of the steel arch assembly machine of the first embodiment. The longitudinal center line is symmetrically arranged on the left and right sides of the main beam 8 of the roadheader, and there is one hydraulic motor 4, which is arranged on one of the upper guide wheels 2. There are two bottom guide wheels 5, which are symmetrically arranged on the left and right sides of the roadheader main beam 8 with the longitudinal centerline of the roadheader main beam 8 as the symmetrical axis. The circular beam 1 is driven to rotate by a hydraulic motor 4 .

Embodiment 3

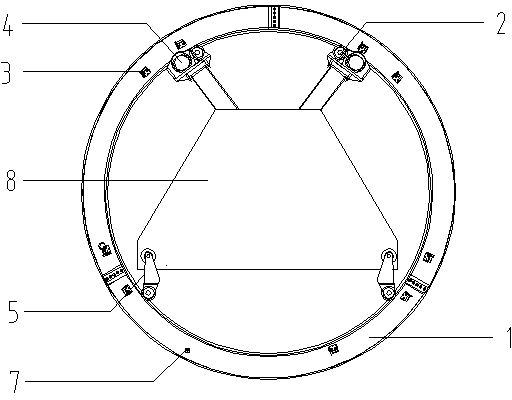

[0036] Such as image 3 As shown, the structure of the steel arch assembling machine of this embodiment is basically the same as that of the steel arch assembling machine of the second embodiment, the difference is that there are two hydraulic motors 4, which are located on one of the upper guide wheels 2 superior. There are two bottom guide wheels 5, which are symmetrically arranged on the left and right sides of the roadheader main beam 8 with the longitudinal centerline of the roadheader main beam 8 as the symmetrical axis. The circular beam 1 is driven to rotate by two hydraulic motors 4, which improves the driving force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com