Systems and methods for identifying environmental conditions

A technology for environmental conditions, ambient humidity, applied in charging systems, exhaust gas recirculation, electrical control, etc., to solve the problem of not accurately tracking condensate levels, insufficiently reducing condensate formation and engine stalls, and inability to accurately track condensate levels. Estimating problems such as condensate formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

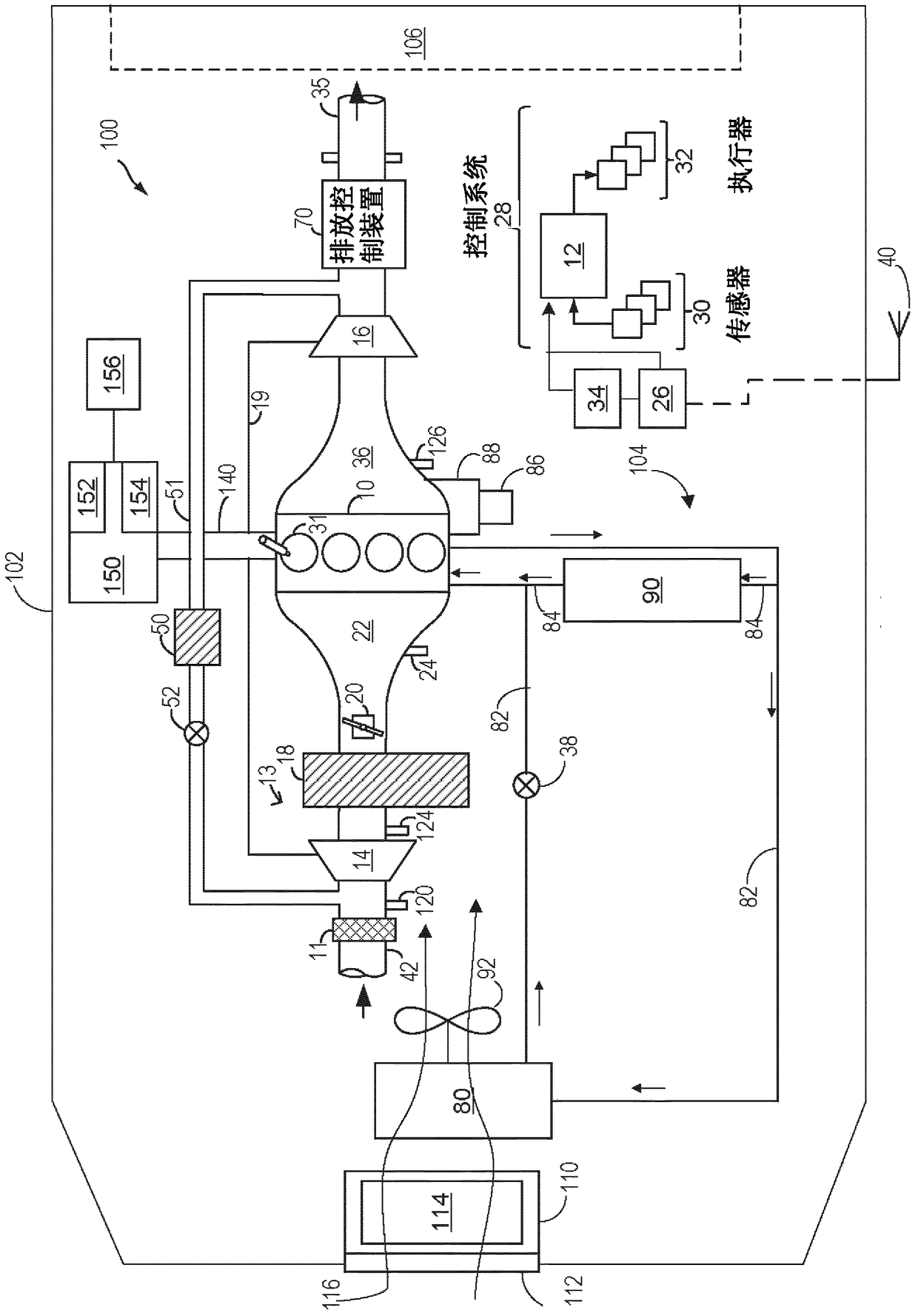

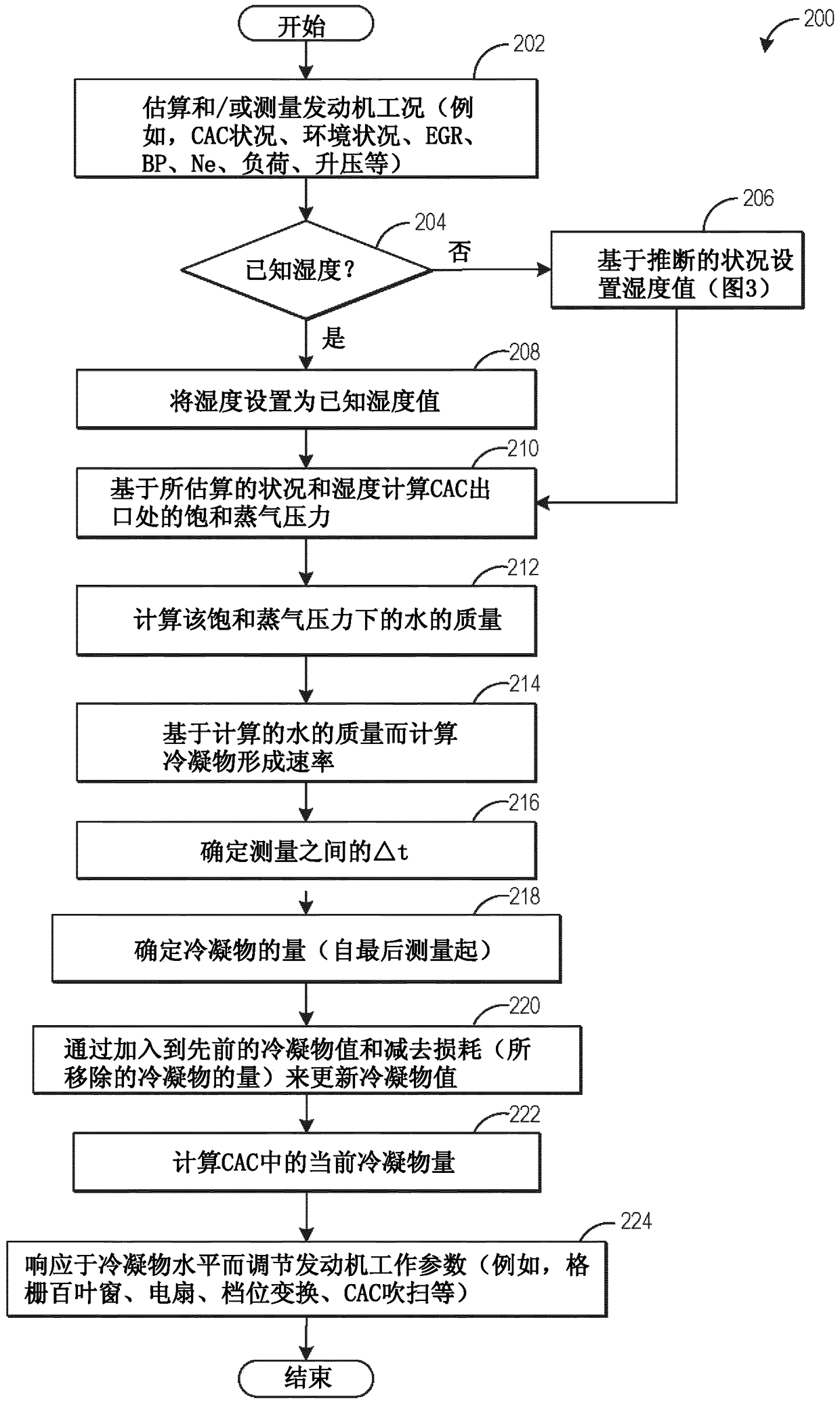

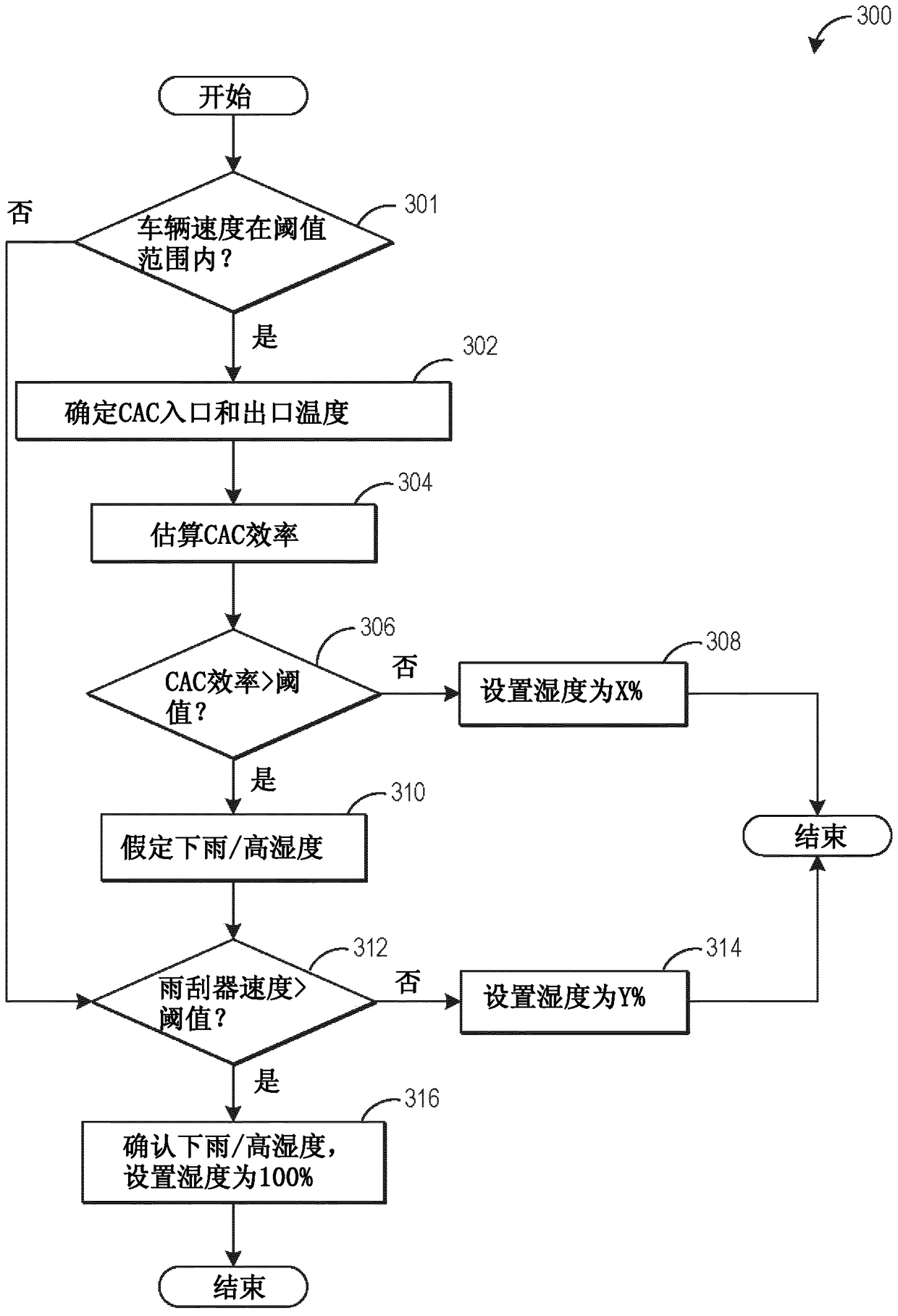

[0022] The following description refers to the use of figure 1 A system and method for estimating ambient humidity from the efficiency of a charge air cooler (CAC) in the system shown). Ambient humidity values can be used in condensate models such as figure 2 shown to determine condensate formation in the CAC. The condensate formation information may then be used to adjust engine actuators and initiate engine control programs to reduce condensate formation and engine stalling. By means of determining a more accurate humidity value, such as image 3 With the method shown, the condensate model can be improved. Windshield wiper speed can be used to confirm high humidity values and infer the presence of rain. Figure 4 Exemplary engine actuator adjustments are presented in response to condensate formation based on humidity values inferred from CAC efficiency and wiper speed.

[0023] figure 1 An exemplary embodiment of an engine system 100 in a schematically illustrat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap