Power distribution cabinet body assembling correction device

A technology for power distribution cabinets and cabinets, which is applied in the field of cabinet assembly and correction devices for power distribution cabinets, can solve the problems of inability to be fixed horizontally, internal components are easily dislocated and damaged, and the upper part is unstable, and achieves good detection effect, reasonable structure, and high reliability. Ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

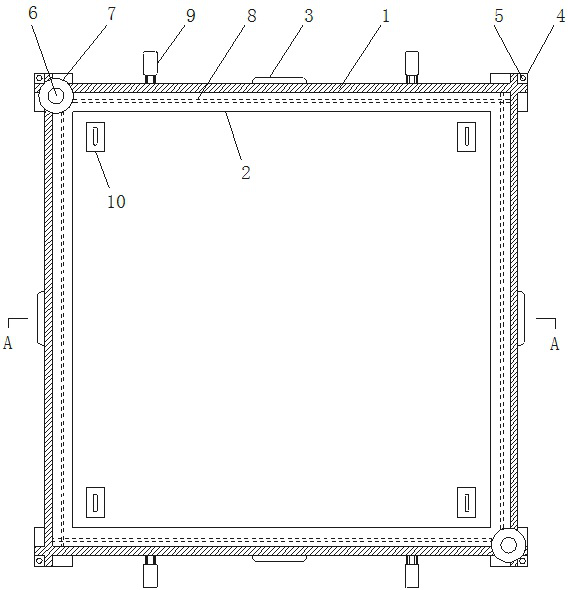

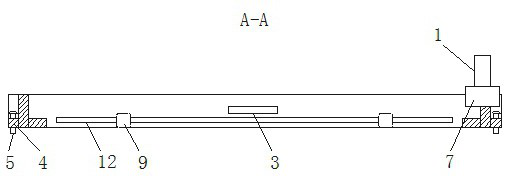

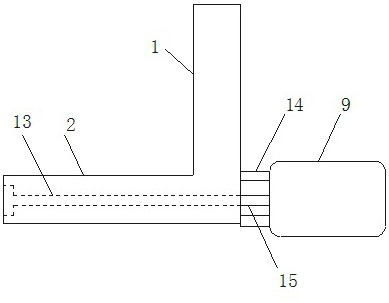

[0019] Such as Figure 1-3 As shown, a power distribution cabinet cabinet assembly correction device, which includes a side baffle 1 and a transverse baffle 2, the side baffle 1 and the transverse baffle 2 are arranged at right angles, and the outer wall of the side baffle 1 is provided with Level ruler 3, the quantity of described side baffle 1 is four, and four side baffles form a square, and the quantity of cross baffle 2 is also four, all vertically arranged with side baffle 1, described cross baffle 2 It is in a horizontal state, and the side baffle 1 is in a vertical state. An adjustment angle 4 is provided at the junction of the side baffle 1 and the cross baffle 2, and an adjustment bolt 5 is arranged on the adjustment angle 4. The side baffle 1 A vertical sliding column 6 is arranged at the junction, and the bottom of the vertical sliding column 6 is fixedly arranged on the horizontal baffle plate 2. A level measuring instrument 7 is arranged on the vertical sliding c...

Embodiment 2

[0022] Such as Figure 1-3 As shown, a power distribution cabinet cabinet assembly correction device, which includes a side baffle 1 and a transverse baffle 2, the side baffle 1 and the transverse baffle 2 are arranged at right angles, and the outer wall of the side baffle 1 is provided with Level ruler 3, the quantity of described side baffle 1 is four, and four side baffles form a square, and the quantity of cross baffle 2 is also four, all vertically arranged with side baffle 1, described cross baffle 2 It is in a horizontal state, and the side baffle 1 is in a vertical state. An adjustment angle 4 is provided at the junction of the side baffle 1 and the cross baffle 2, and an adjustment bolt 5 is arranged on the adjustment angle 4. The side baffle 1 A vertical sliding column 6 is arranged at the junction, and the bottom of the vertical sliding column 6 is fixedly arranged on the horizontal baffle plate 2. A level measuring instrument 7 is arranged on the vertical sliding c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap