VAV ventilation system

A ventilation system and variable air volume technology, applied in the field of ventilation systems, can solve the problem of difficulty in ensuring stable air supply from ventilation branch pipes, difficulty in effectively responding to pressure changes in main ventilation pipes with a single static pressure sensor, and difficulty in determining the proper position of a single static pressure sensor, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

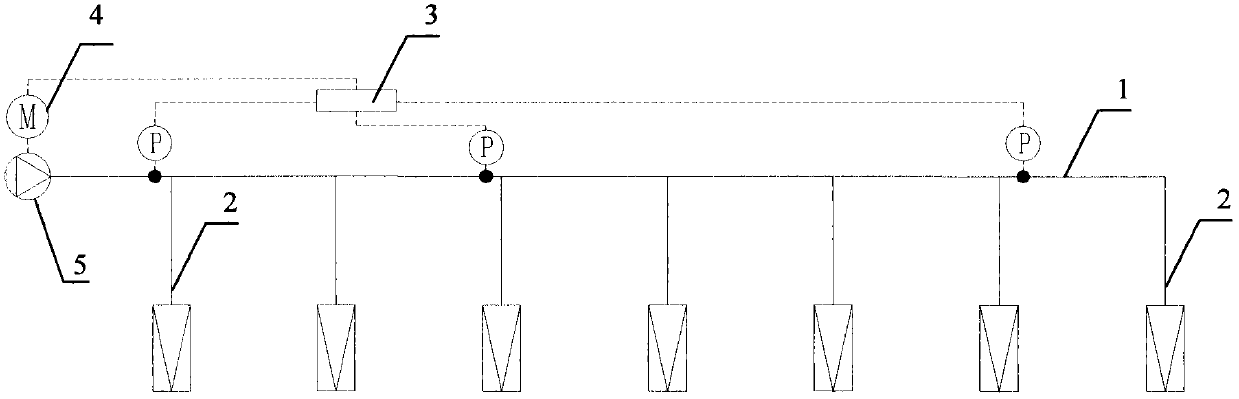

[0010] Embodiment 1: see attached figure 1 , a variable air volume ventilation system, comprising: a main ventilation pipe 1 and a multi-channel ventilation branch pipe 2, characterized in that it also includes: a plurality of static pressure sensors P, a PLC controller 3, a fan frequency converter 4 and a total frequency conversion fan 5;

[0011] The plurality of static pressure sensors P are arranged at different positions in the main ventilation pipe 1, and convert the real-time static pressure value and pressure distribution in the main ventilation pipe 1 into electrical signals;

[0012] The PLC controller 3 receives the electrical signals transmitted by the plurality of static pressure sensors P, and after weighted calculation and comparison with the set pressure value, sends a corresponding frequency conversion command to the fan frequency converter 4;

[0013] The fan frequency converter 4 changes the frequency according to the frequency conversion command issued by t...

Embodiment 2

[0014] Embodiment 2: The variable air volume ventilation system as described in Embodiment 1, when the number of the ventilation branch pipes 2 is ≤ 4, the static pressure sensor P is 2; when the number of the ventilation branch pipes 2 is ≥ 5, the There are 3 or more static pressure sensors P, one of which is arranged in front of the first and the last ventilation branch pipe 2 respectively.

Embodiment 3

[0015] Embodiment 3: The variable air volume ventilation system as described in Embodiment 1 or 2 is characterized in that: the weight distribution of the weighted calculation is: when there are 2 static pressure sensors P, at the near end of the total frequency conversion fan 5 0.35, 0.65 at the far end; when there are 3 static pressure sensors P, the near end of the total frequency conversion fan 5 is 0.2, the middle end is 0.3, and the far end is 0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com