Installation method of energy-saving component

An installation method and component technology, applied in heating methods, space heating and ventilation details, household heating, etc., can solve the problems of decreased air volume, longer working hours of equipment, and increased energy consumption, so as to improve heat exchange efficiency , good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

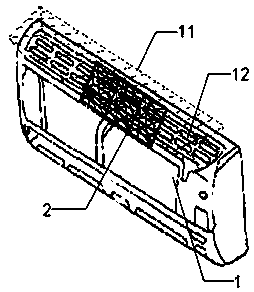

[0044] Such as Figure 1 to Figure 2 As shown, the energy-saving component 2 can be a sheet structure with a certain thickness, and the energy-saving component 2 has an effective use surface 21 , which needs to be arranged facing the heat exchange device when in use. exist image 3 shows the installation method of the energy-saving component 2 with openings on the wall-mounted air conditioner. During installation, it is necessary to check the area of the effective airflow passage section 11 of the air inlet air path above the heat exchange equipment. If the area of the energy-saving component is greater than / If the area of the effective airflow passing section 11 of the air inlet airflow path of the heat exchange device is smaller than that, cutting / joining is required. The cut effective surface area of the energy-saving component 2 should be at least not less than 30% of the effective airflow passage section 11 . The cut energy-saving component 2 is arranged in th...

Embodiment 2

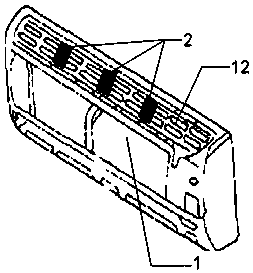

[0046] The same wall-mounted air conditioner, but if the energy-saving component 2 does not have openings, Figure 4 To show its installation method, it is also necessary to cut / assemble the energy-saving component 2 according to the same principle, so that the total effective use area of the energy-saving component 2 meets the above requirements, but since the surface of the energy-saving component 2 does not have openings, the air volume passing through The energy-saving component 2 with openings on the surface, therefore, the energy-saving component 2 is divided into multiple pieces for installation, preferably according to Figure 4 The shown left, middle and right places are installed so that air turbulence can be formed between any two energy-saving components 2 . During installation, it is also necessary to ensure that there is a certain clearance from the air inlet 12. If the clearance requirement is not met, the energy-saving component 2 can still be bent to form an...

Embodiment 3

[0048] Figure 5 to Figure 6 The installation method of energy-saving components on the floor-standing air conditioner is shown. The air inlet device of the floor-mounted air conditioner heat exchange device 1 is also called a black hole fan. The front will inevitably cover a whole face shell to achieve the effect of protection and beauty. Therefore, the smoothness of the air intake directly in front of the black hole fan is completely hindered. Therefore, in order to ensure the air intake of the floor-standing air conditioner heat exchange device 1, the air conditioner manufacturer will open a plurality of vents on both sides and the bottom of the shell, such as the left air inlet 15, the lower air inlet 14, and the right air inlet 12. Because the air suction method of the floor-standing air conditioner is quite different from other air conditioners, it is necessary to calculate the effective air intake cross-sectional area of the black hole fan before installation, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com