Exhaust system controller

A system controller and main control unit technology, applied in program control, computer control, general control system, etc., can solve the problems of fixed exhaust air volume and inability to adjust the kitchen independently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

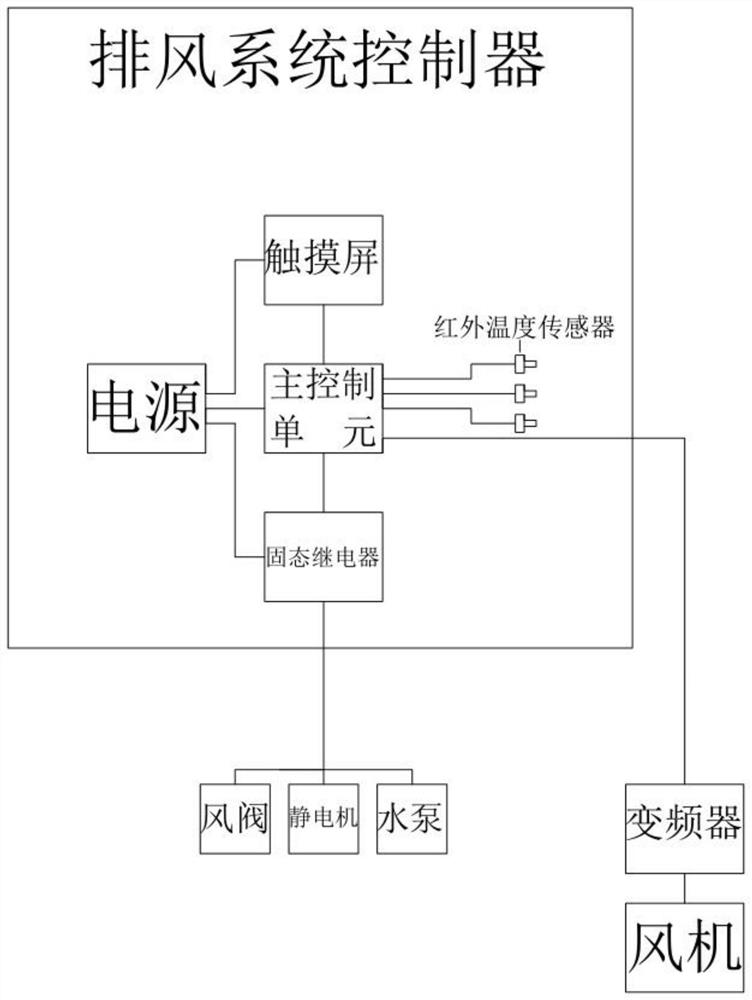

[0015] like figure 1 As shown, the exhaust system controller includes a main control unit, an infrared temperature sensor, a solid state relay, a touch screen, and a power supply. The infrared temperature sensor senses the temperature of the furnace head and converts it into an electronic signal and transmits it to the main control unit. The main control unit monitors the temperature of the furnace head. When the temperature of the furnace head reaches the preset value, it controls the solid state relay to turn on the electrostatic motor, the water pump and the corresponding air valve. And control the frequency of the frequency converter to adjust the air volume of the fan. The main control unit divides the frequency of the frequency converter into several levels according to the working state of each burner, and each level corresponds to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com