How to make a transparent antenna

A manufacturing method and antenna technology, applied in antenna support/mounting device, gaseous chemical plating, metal material coating process, etc., can solve problems such as unfulfilled requirements and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

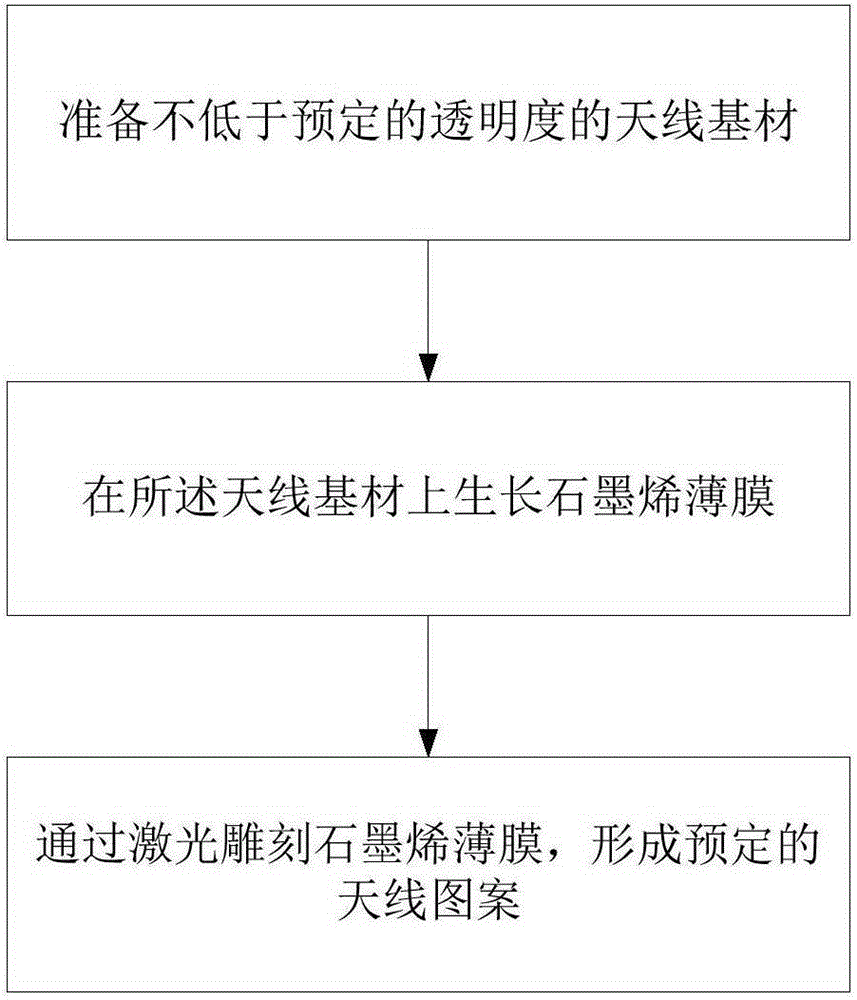

Method used

Image

Examples

Embodiment 1

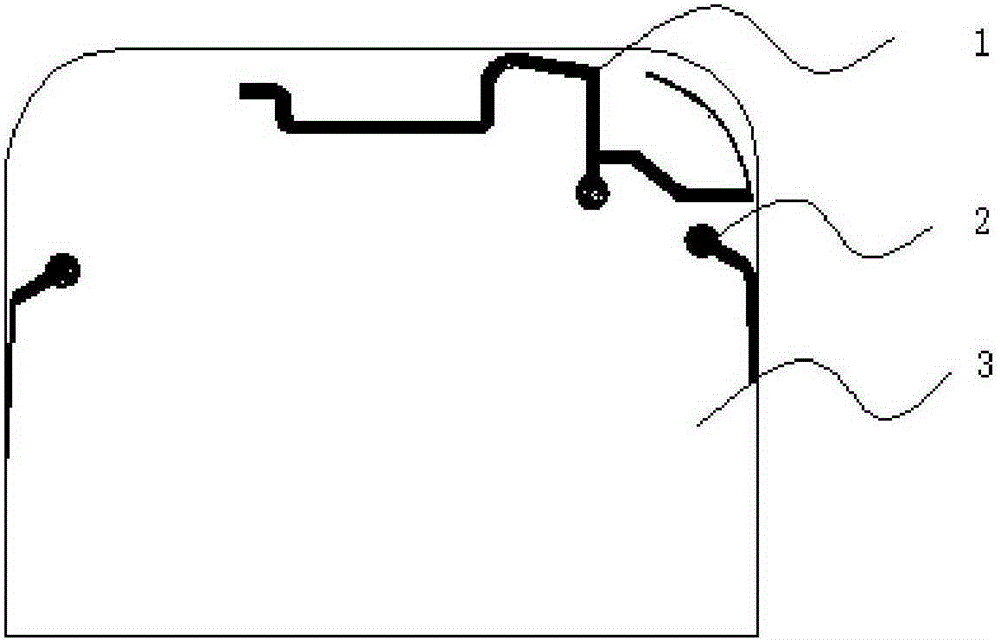

[0057] refer to figure 1 , Figure 1a and Figure 1b .

[0058] 1. Select glass as the antenna substrate

[0059] Glass surface treatment, polishing process conditions:

[0060] The concentration of polishing liquid is 1.1, the spindle speed is 25R / M, the pressure is 60KG, and the time is 40min.

[0061] 2. Cleaning

[0062] Ultrasonic process cleaning, ultrasonic power 60W, ultrasonic frequency 40KHz, heating power 100W, temperature 55 ℃, time 10min. The drying temperature is 55°C, and the drying time is 8 minutes.

[0063] 3. Use a jig to expose the antenna pattern. The size of the antenna pattern is controlled to 0.05~1mm, and all other parts are covered. There is a cushioning material on the jig contacting the antenna carrier to avoid scratching the antenna substrate.

[0064] 4. Growth of graphene nanofilm on glass

[0065] First turn on the vacuum pump, vacuum, when the vacuum reaches 10 -6 , the substrate glass is heated, the temperature is raised to 450°C, clo...

Embodiment 2

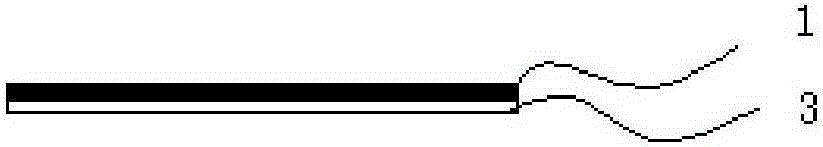

[0070] refer to figure 2 , Figure 2a and Figure 2b .

[0071] 1. Prepare the antenna substrate film, preferably PET film, preferably with a thickness of 0.1-0.15 mm, more preferably 0.11 mm. Thin films such as PMMA and PC can also be used.

[0072] 2. Coating graphene nano-film on PET film sheet

[0073] First turn on the vacuum pump, vacuum, when the vacuum reaches 10 -6 , heat the PET sheet, raise the temperature to 215°C, and fill it with inert gas and carrier gas, and control the flow rate; when the temperature in the center of the furnace body reaches 1000°C, feed the carbon source, control the flow rate, start deposition, and keep it for 25 minutes, with the help of carrier gas Cool to room temperature.

[0074] 3. Make PET graphene transparent antenna sheet

[0075] First, directly import the antenna pattern on the laser machine software, or draw it directly, and use the laser to engrave the antenna pattern to make a PET graphene antenna sheet. One PET graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com