Electric junction box

A technology for electrical junction boxes and junction boxes, applied in the direction of electrical components, etc., can solve problems such as weight increase, space waste, misinstallation, etc., and achieve the effect of reducing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

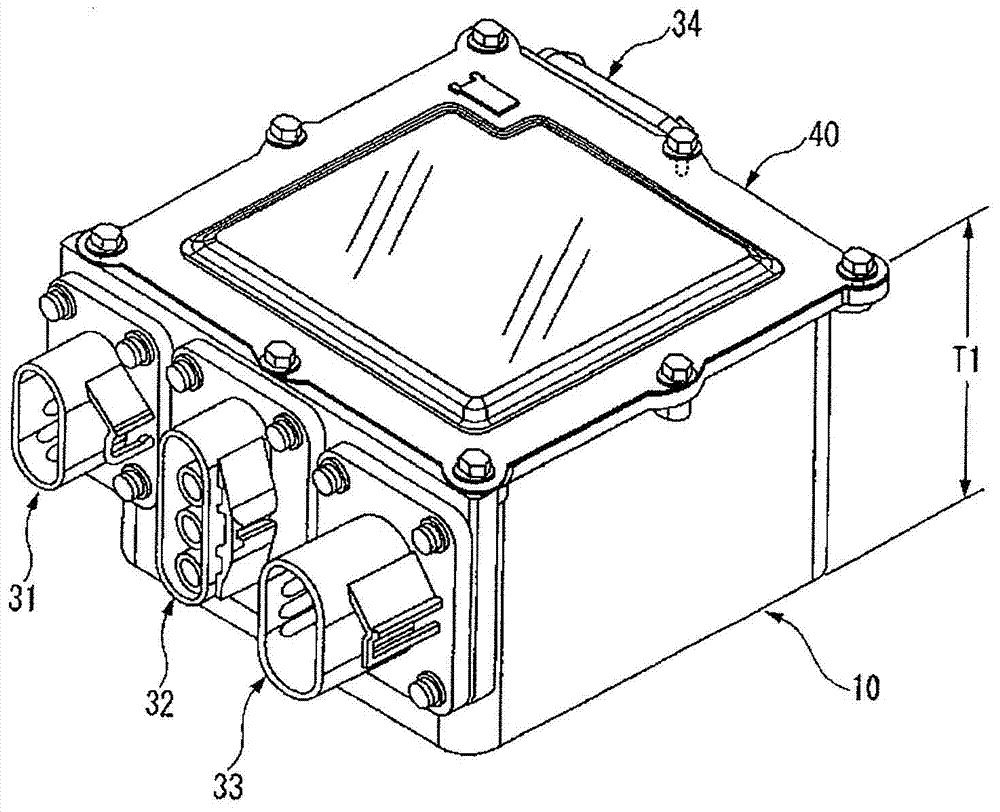

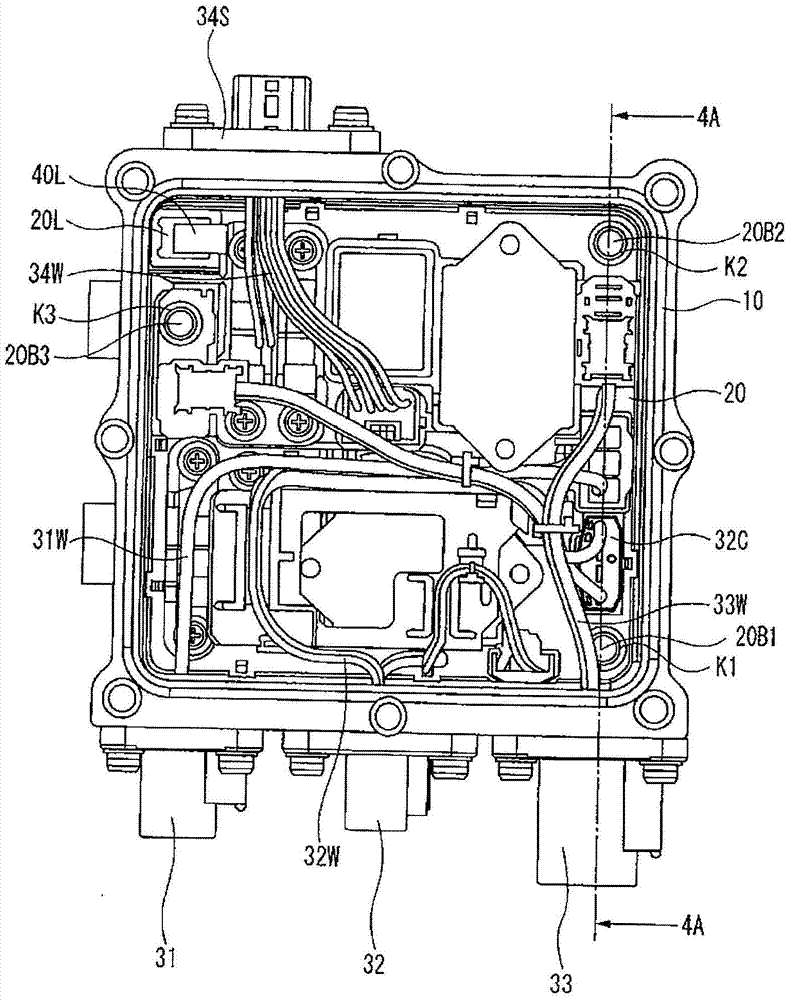

[0077] Below, based on Figure 1 to Figure 5 The electrical junction box of the present invention will be described. According to the electrical junction box of the present invention, even when the shape of the shielding box is square, there is no misinstallation of the junction box, no waste of space and no increase in weight, the moment of inertia at the time of vibration can be reduced, and the Optimal positioning of junction boxes.

[0078]

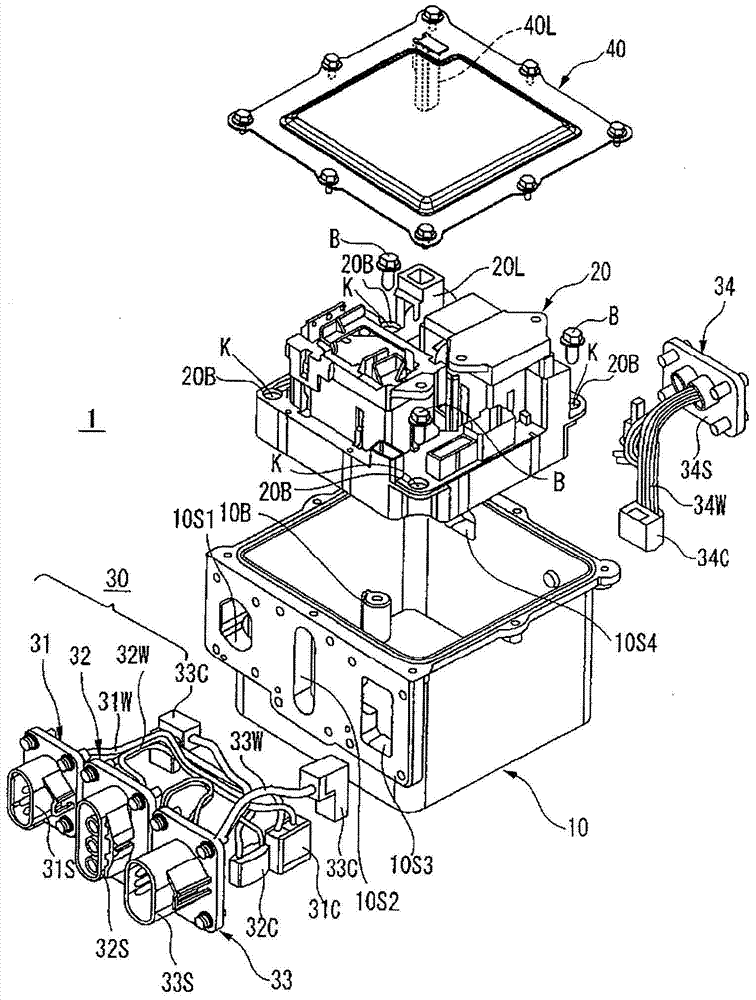

[0079] figure 1 It is an exploded perspective view of the electrical junction box of the present invention.

[0080] exist figure 1 Among them, the electrical junction box 1 of the present invention has: a shielding box 10, a junction box 20 accommodated in the shielding box 10, and an electrical component such as a fuse and a relay for connecting the electrical components such as a fuse and a relay in the junction box 20 to an external storage battery and inverter. The in-vehicle wiring 30 electrically connected to electronic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com