Grate for crusher

A technology of crusher and grate plate is applied in the field of crushing equipment in the sintering machine of iron and steel plant, which can solve the problems of falling blocks, falling off of wear-resistant alloy layer, shortening the service life of the grate plate, etc., so as to improve the service life, avoid wear, improve the The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

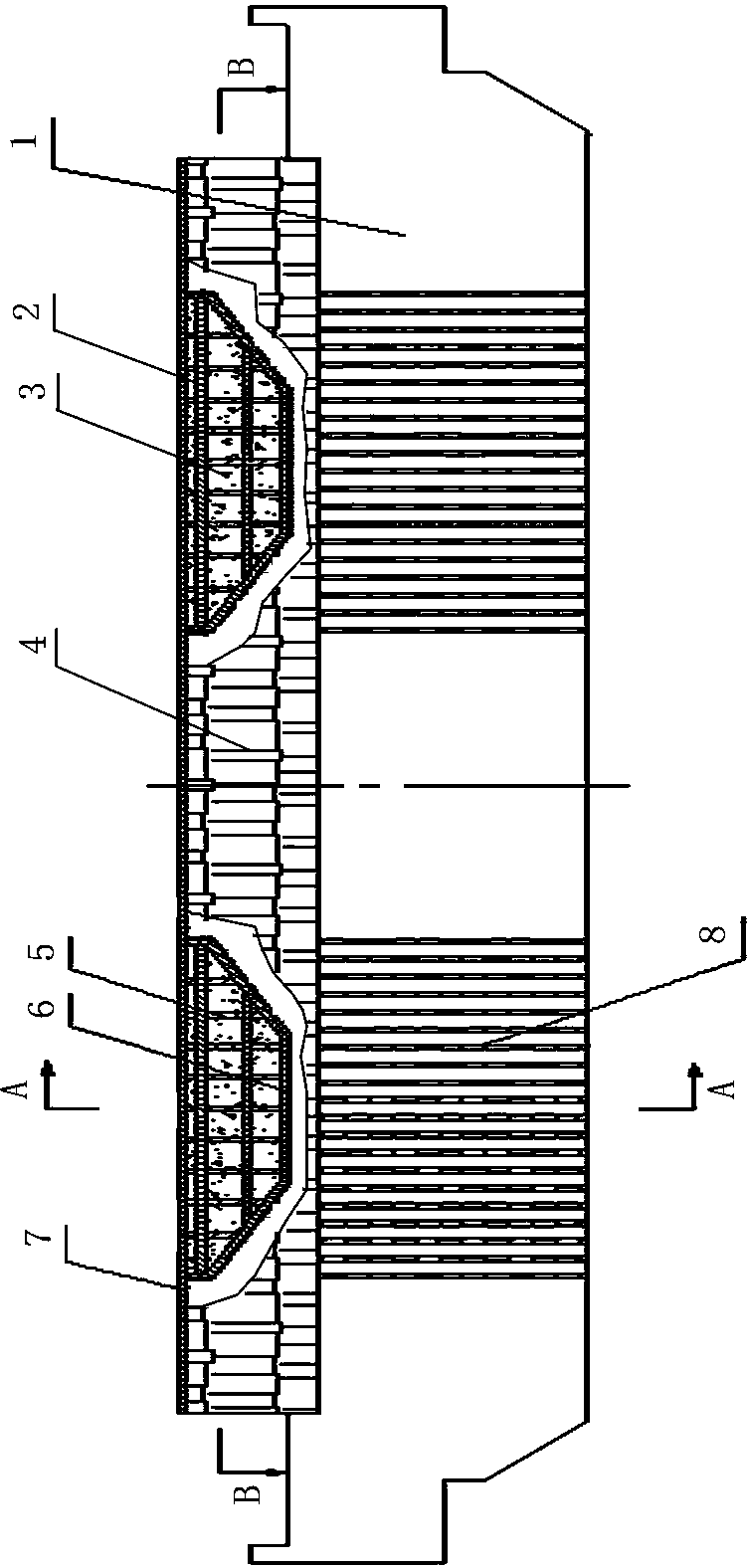

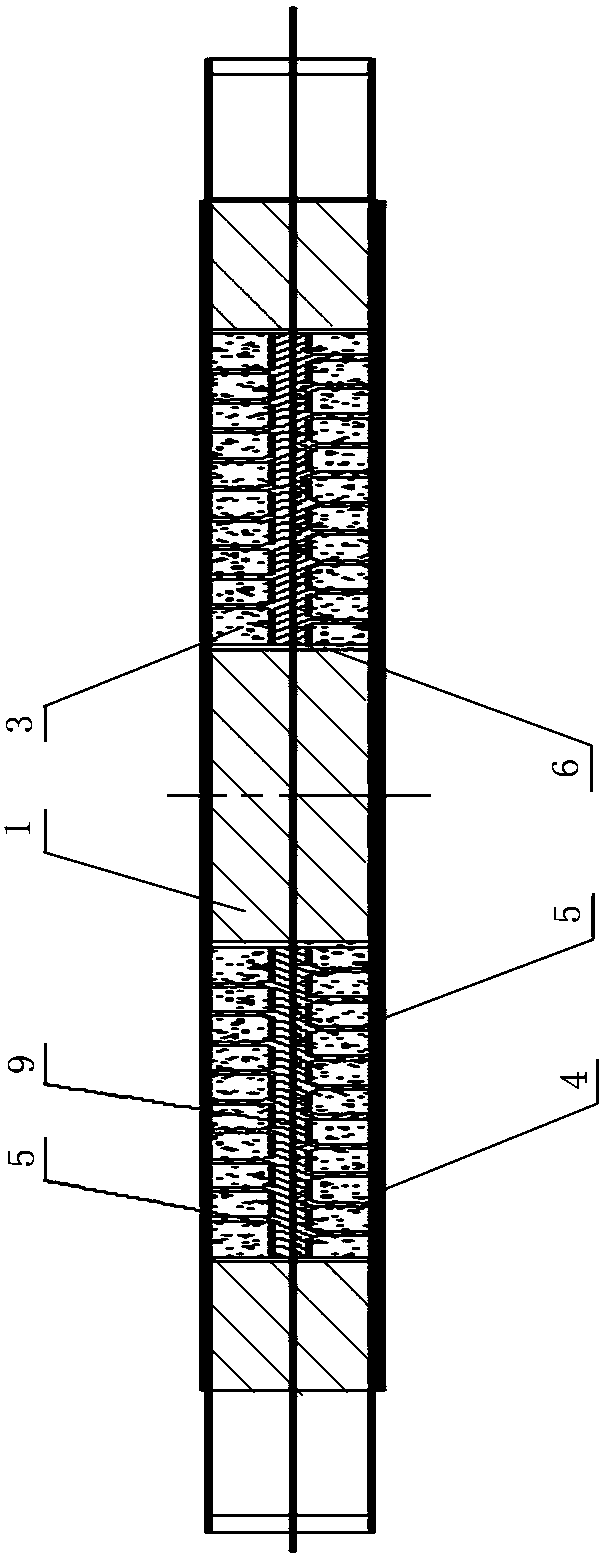

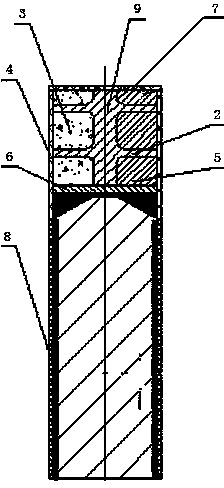

[0028] like Figure 1-Figure 3 The shown grate plate of the present invention includes the following structure: the fitting position of the grate plate body 1 is provided with two grooves; the transverse middle of the groove is provided with a vertical rib that matches the shape of the groove. 9; In the two areas divided by the vertical bars 9, separate rib plates 5 are set up longitudinally staggered; The height of the upper horizontal plate should be lower than the height of the grate plate body 1 , and the wear-resistant alloy 3 is filled in the grid area formed by the vertical rib 9 , the spacer rib plate 5 and the horizontal plate 2 .

[0029] The above-mentioned upper end surface of the grate plate body 1 is also surfacing with a wear-resistant and high-temperature resistant alloy layer 7 so as to be closely connected with the grate plate body 1 .

[0030] A wear-resistant and high-temperature-resistant alloy layer 4 is also surfacing on the side surface of the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com