Apparatus used for manufacturing warm and cold swaging stay tube and method for manufacturing lead sleeve by using apparatus

A technology of equipment and heating body, applied in the field of manufacturing pipe fittings, can solve the problems of poor product quality, environmental pollution, energy consumption of consumables and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

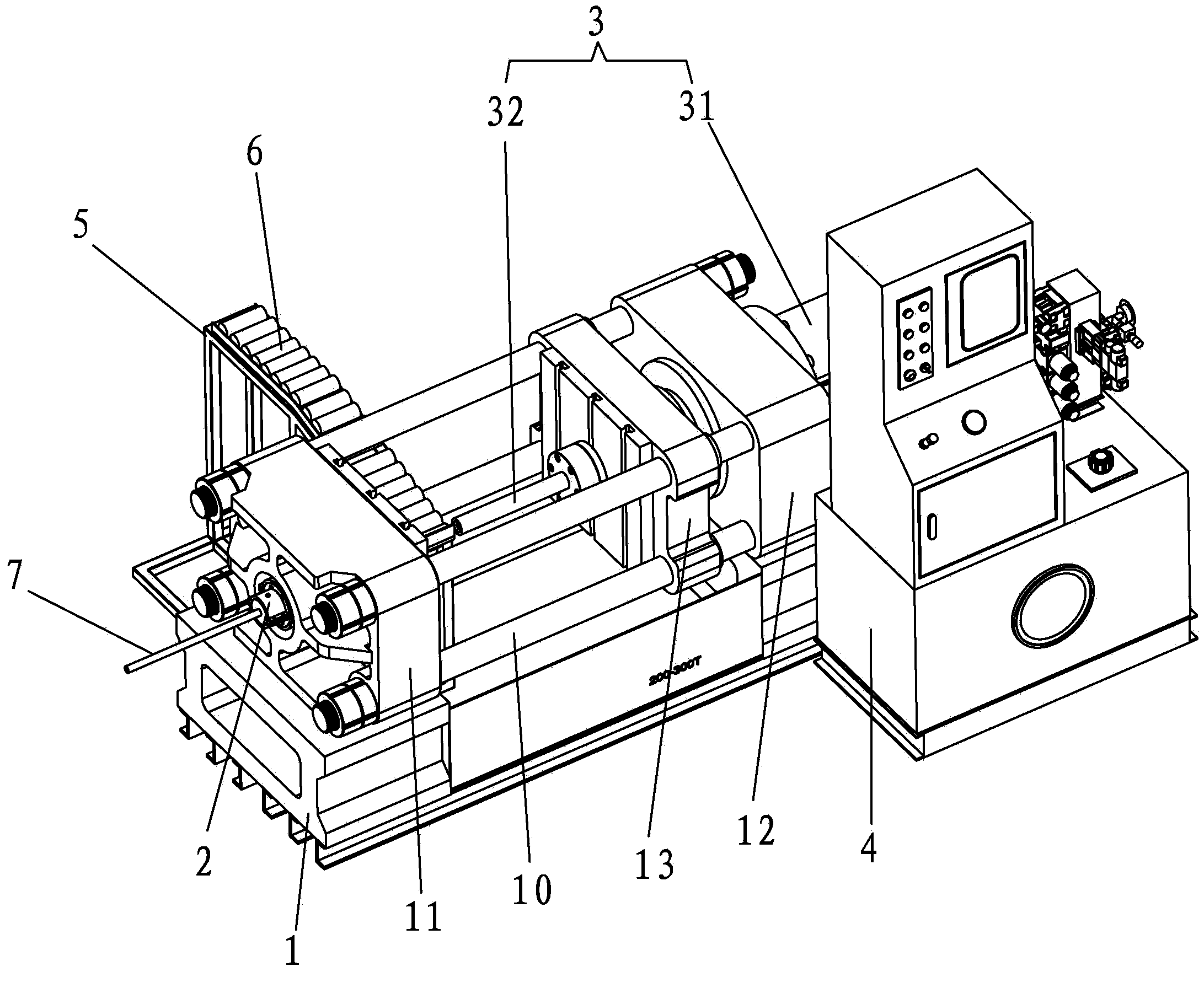

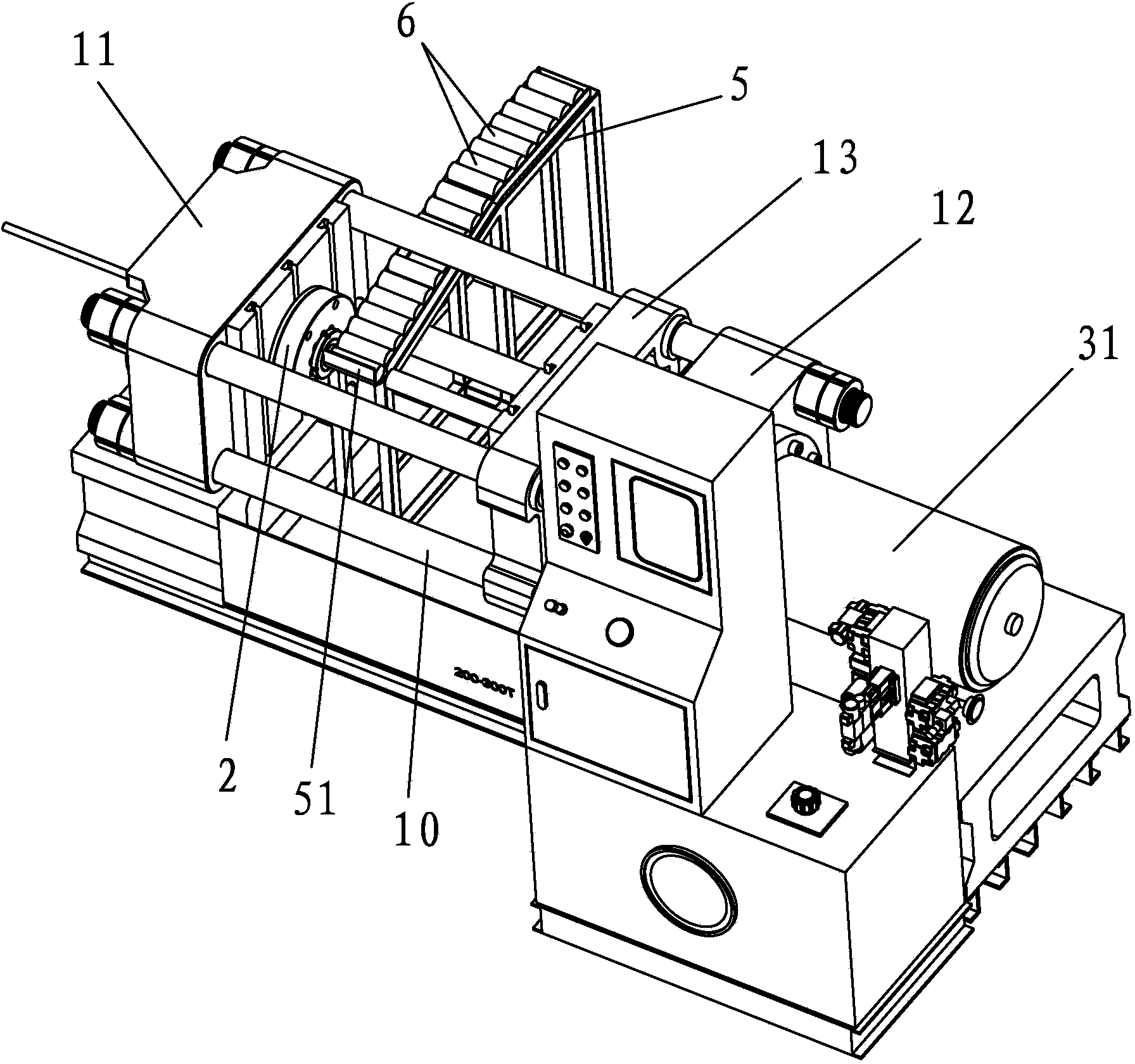

[0041] This case involves a kind of equipment for manufacturing warm and cold extruded forged pipes, such as Figure 1-5 As shown, it mainly includes a base 1 , an extrusion head mechanism 2 and an extrusion driving mechanism 3 arranged on the base 1 .

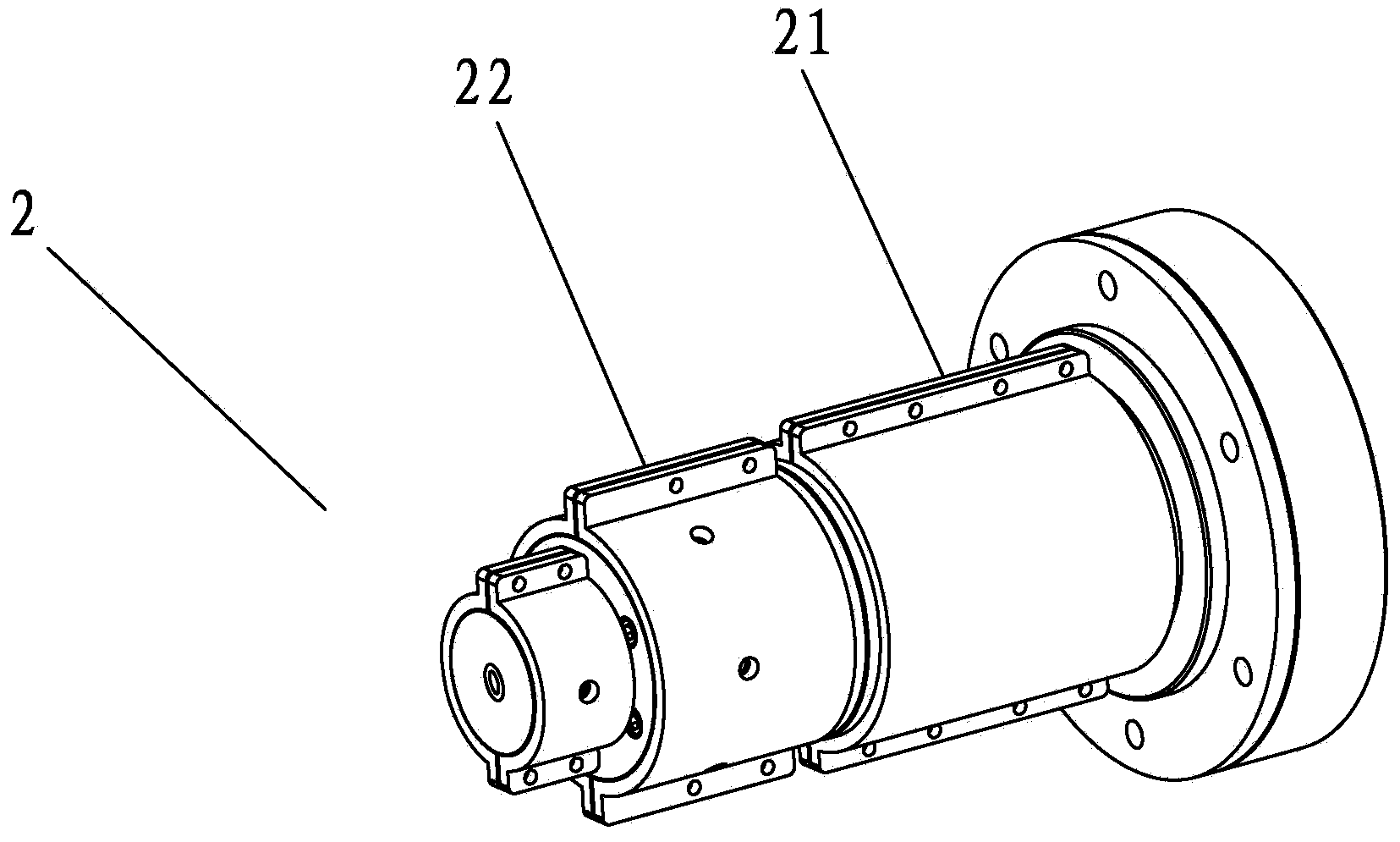

[0042] The extruder head mechanism 2 mainly includes a main body 21 and a heating body 22 , and the heating body 22 is connected to one end of the main body 21 . The main body 21 is axially provided with a through channel. Preferably, the channel includes an extrusion straight channel 211 and a feeding shrinkage channel 212. ) has an inlet 210. The heating body 22 is provided with a through annular heating flow channel along the axial direction. The heating flow channel includes a heating expansion channel 221, a heating shrinking channel 222 and an extrusion straight channel 223, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com