Engine hoisting structure

An engine and hoisting technology, which is applied in the hoisting structure of aero-engines and the field of engine hoisting structures, can solve the problems such as the large influence of the aerodynamic performance of the engine, and achieve the effect of small aerodynamic performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

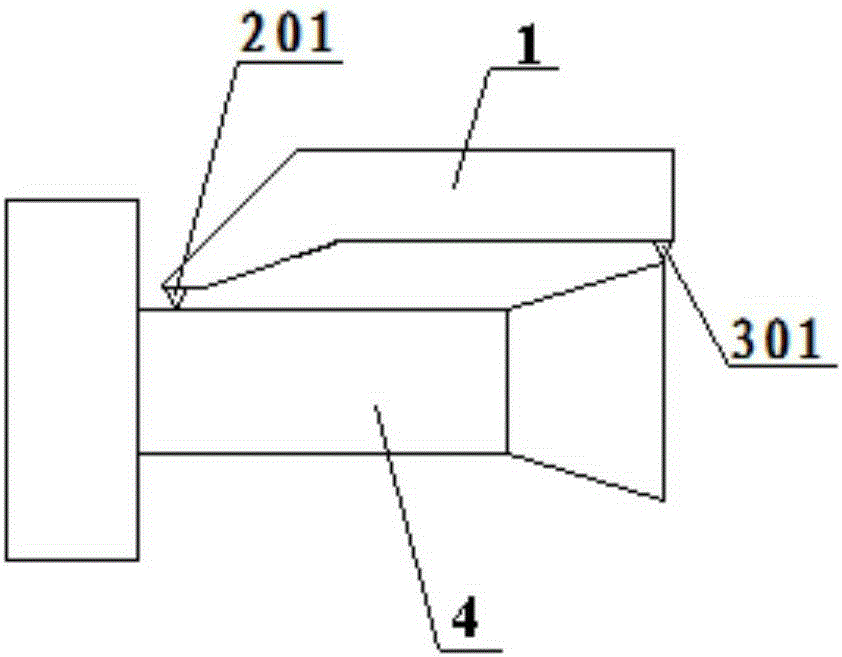

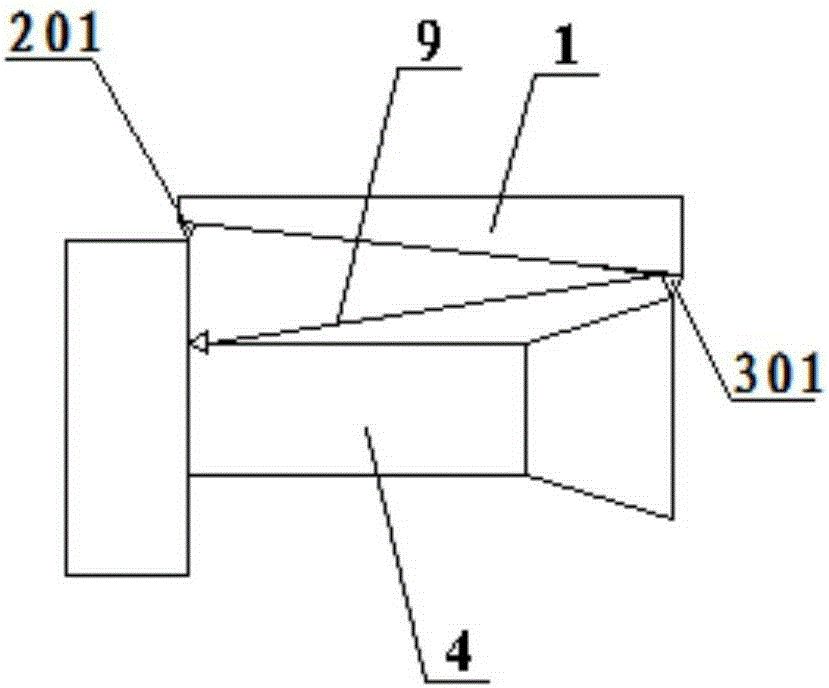

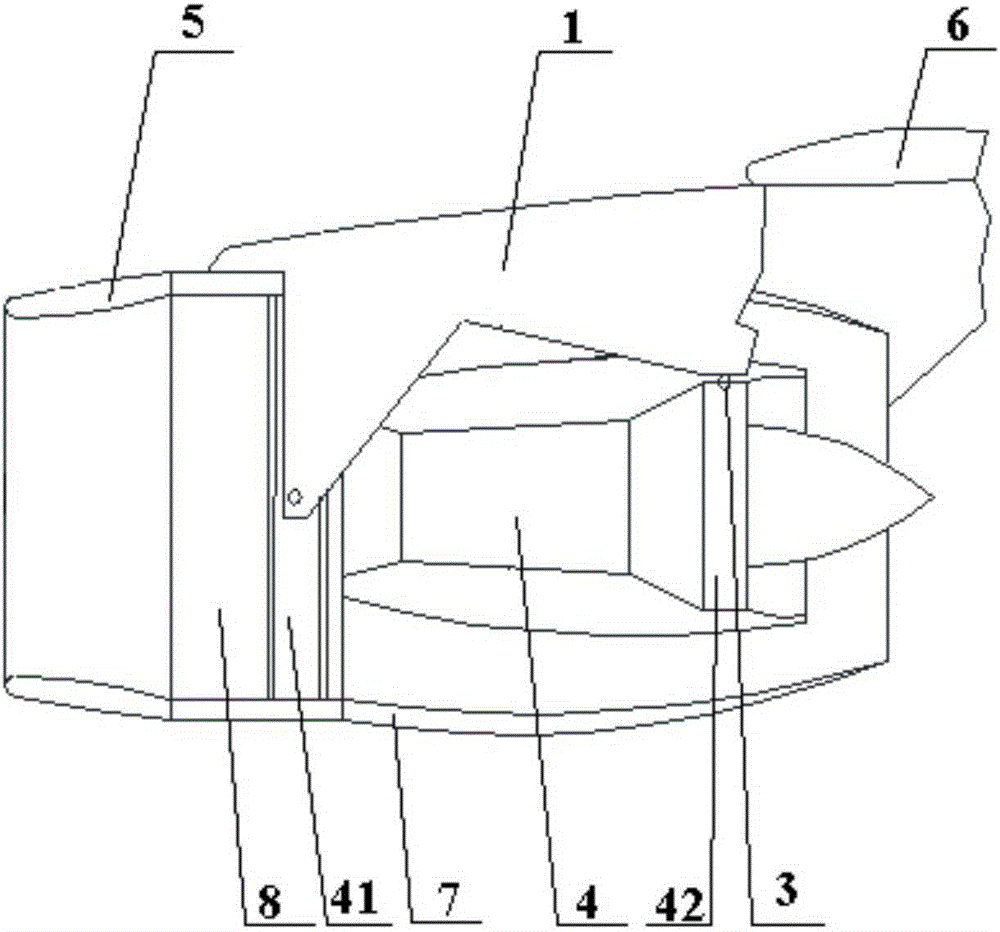

[0049] Below through the accompanying drawings Figure 3 ~ Figure 6 As well as listing some optional embodiments of the present invention, the technical solutions (including preferred technical solutions) of the present invention are further described in detail. It should be noted that: any technical feature in this embodiment (the technical features can be separated by any punctuation marks such as commas, periods, commas or semicolons), and any technical solution is a variety of optional technical features or One or several of the optional technical solutions, for the sake of brevity in description, it is impossible to list all the alternative technical features and alternative technical solutions of the present invention in this document, and it is not convenient for the implementation of each technical feature It is emphasized that it is one of multiple optional implementation modes, so those skilled in the art should know: any technical feature and any technical scheme in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com