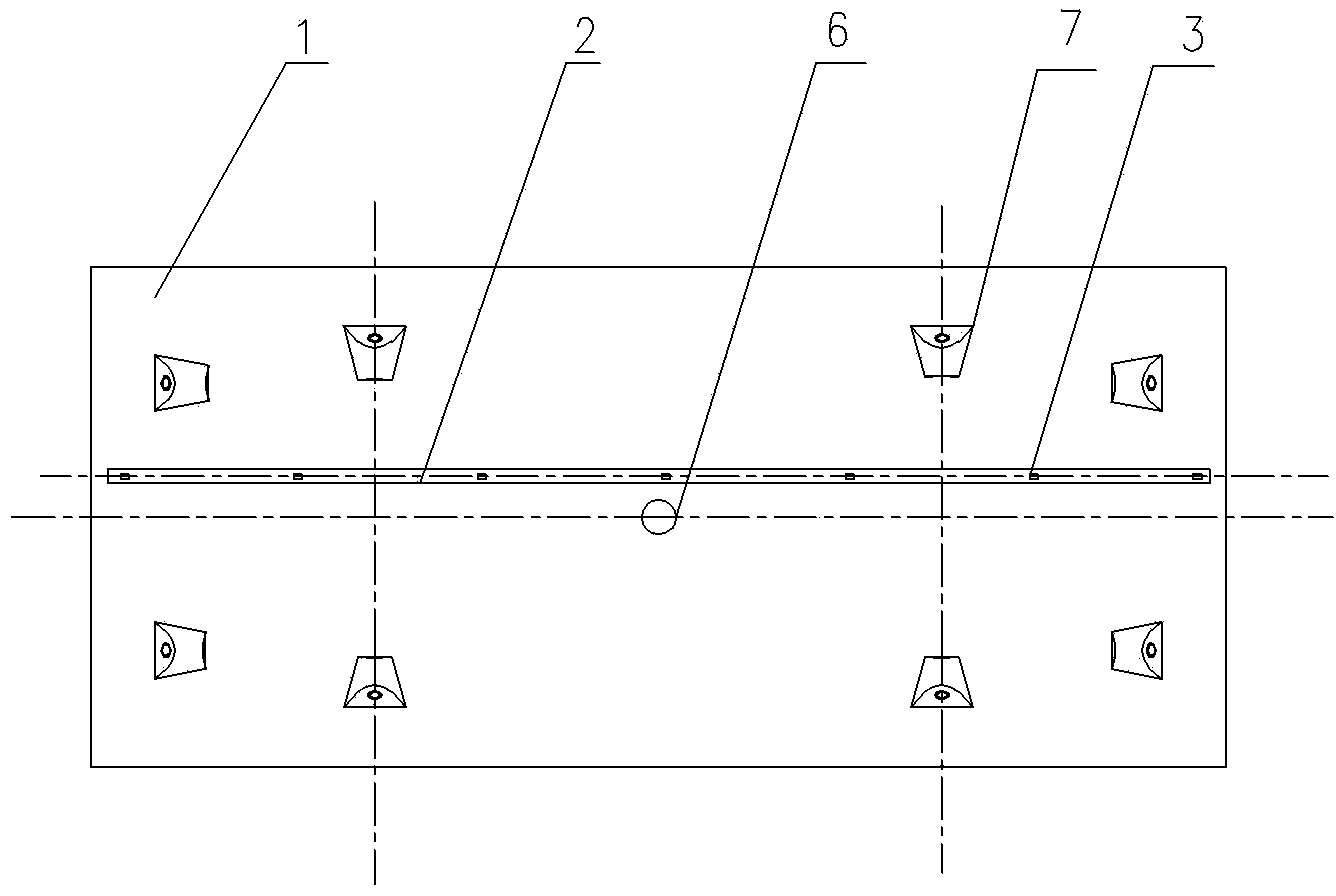

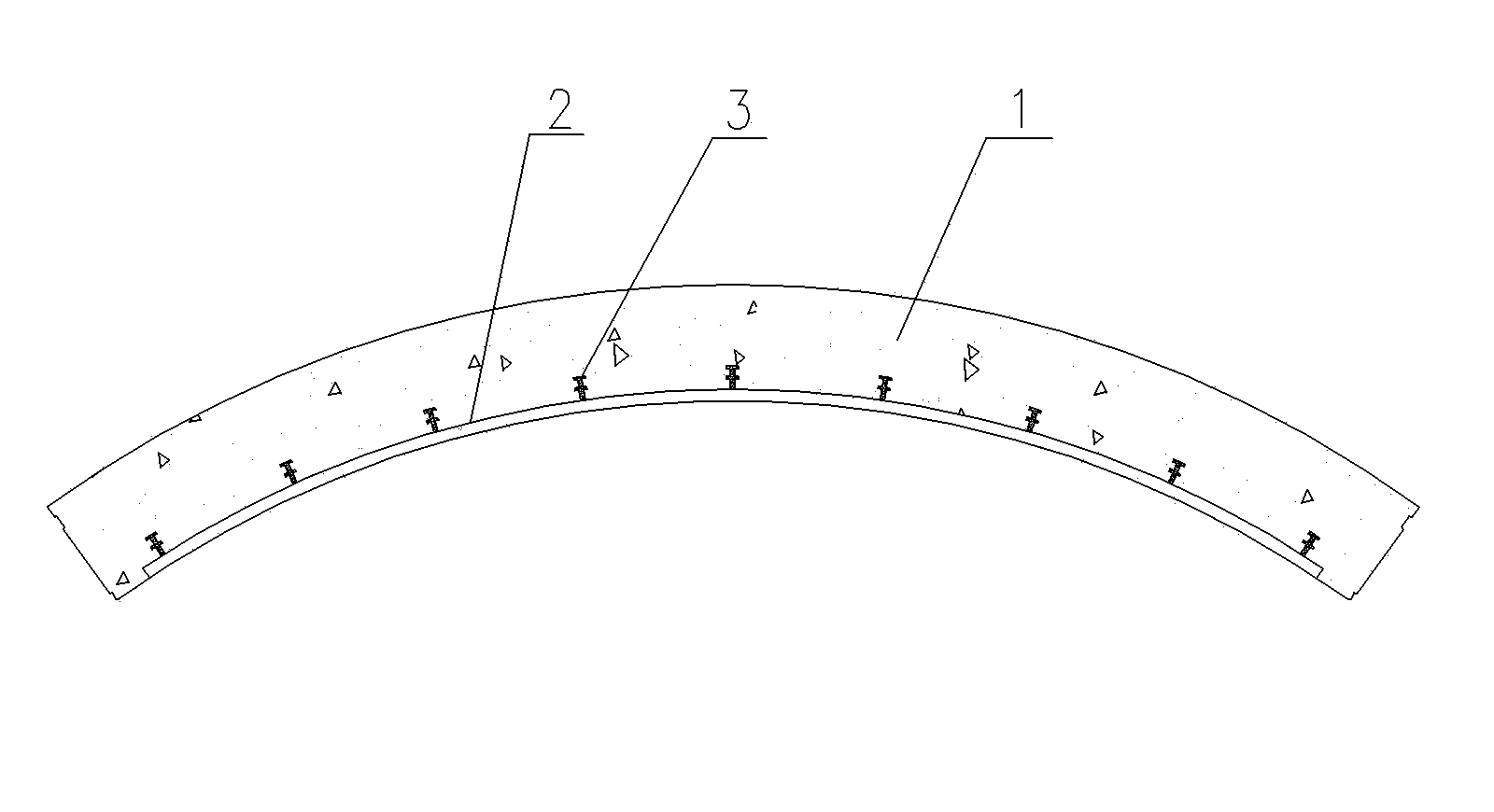

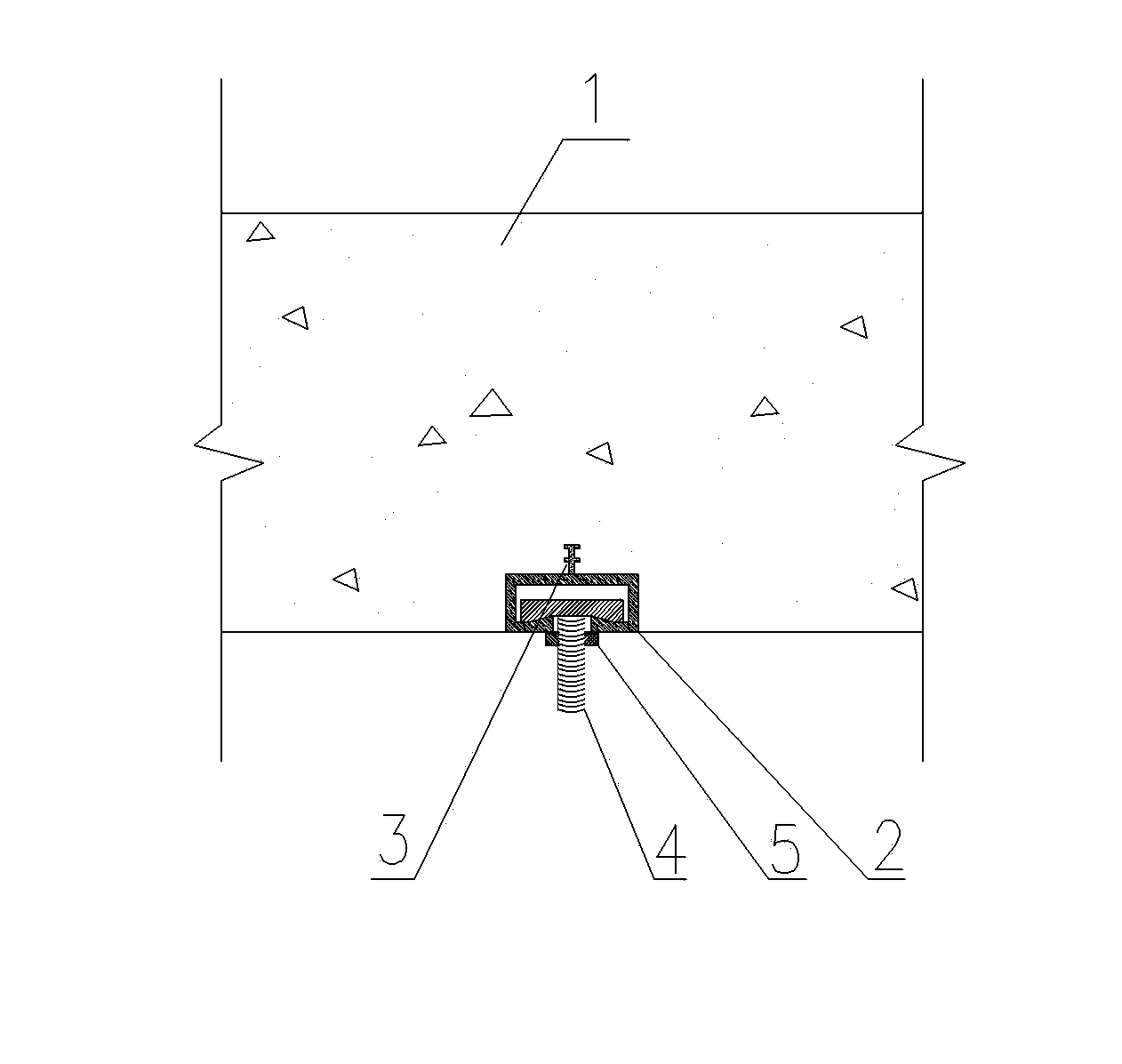

Shield method tunnel lining structure pre-buried groove connecting element and installing method thereof

A technology of groove connection and shield method, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of failure to achieve the century-old engineering design goal, difficulty in meeting the stability and durability of connecting parts, and affecting the long-term durability of tunnels, etc. , to achieve the effect of reducing potential quality hazards, avoiding adverse effects, and reducing repair and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

[0029] Based on the current technical level, after the tunnel is penetrated, holes or grooves are drilled or slotted on the surface of the lining structure to add equipment installation connectors, without adversely affecting the integrity and durability of the lining structure, and at the same time, it is also necessary to ensure the long-term satisfaction of various equipment. The purpose of safe use is still quite difficult. Because in the process of drilling or slotting on the surface of the lining structure, it is impossible to effectively avoid the main stress steel bars inside the lining structure, and it is impossible to avoid the cracking, partial breaking or even falling of the lining structure caused by local stress concentration, and it is impossible to fundamentally eliminate the drilling. Or the leakage of water at the groove, and it is even more difficult t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com