A control system and working method of an intelligent electric actuator

A technology of electric actuators and control systems, which is applied in the direction of engine components, valve operation/release devices, mechanical equipment, etc., can solve the problems of affecting the system stability, service life of electric actuators, low position accuracy, etc., and achieve intelligent improvement Good performance and damping characteristics, and the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

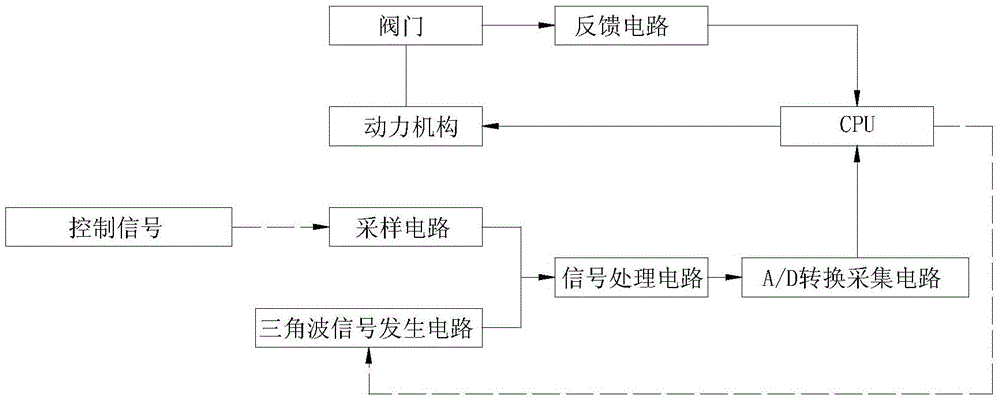

[0039] The present invention as Figure 1-9 As shown, the electric actuator includes a power mechanism and a control system, and the valve is driven by the power mechanism to open and close;

[0040] The control system includes a CPU, a triangular wave signal generating circuit, a sampling circuit, a signal processing circuit, an A / D conversion acquisition circuit and a feedback circuit;

[0041] Control the power mechanism and the triangular wave signal generating circuit through the CPU; compare the signals sent by the sampling circuit and the triangular wave signal generating circuit through the signal processing circuit, and process the generated results through the A / D conversion acquisition circuit After that, it is sent to the CPU; the feedback state (that is, the current real-time position state of the valve) is fed back to the CPU through the feedback circuit.

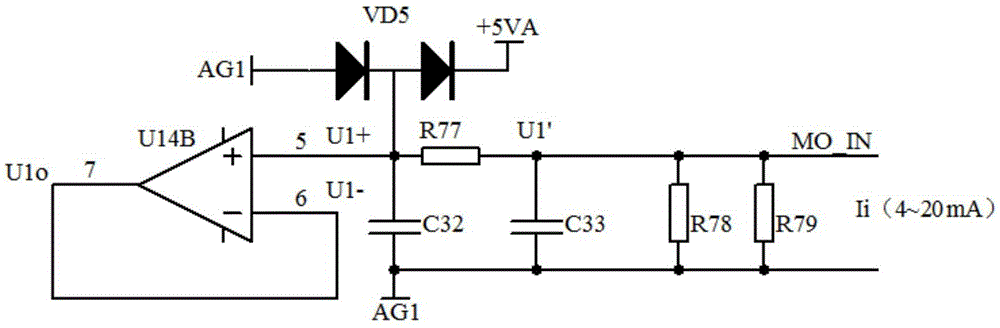

[0042] The sampling circuit includes a sampling resistor, an RC filter circuit, and a voltage follower cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com