Vacuum valve bank box for LNG (Liquefied Natural Gas) liquid-adding machine

A technology of vacuum valve and liquid filling machine, which is used in mechanical equipment, gas/liquid distribution and storage, equipment loaded into pressure vessels, etc. problems, to achieve the effect of convenient maintenance and increased thermal insulation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

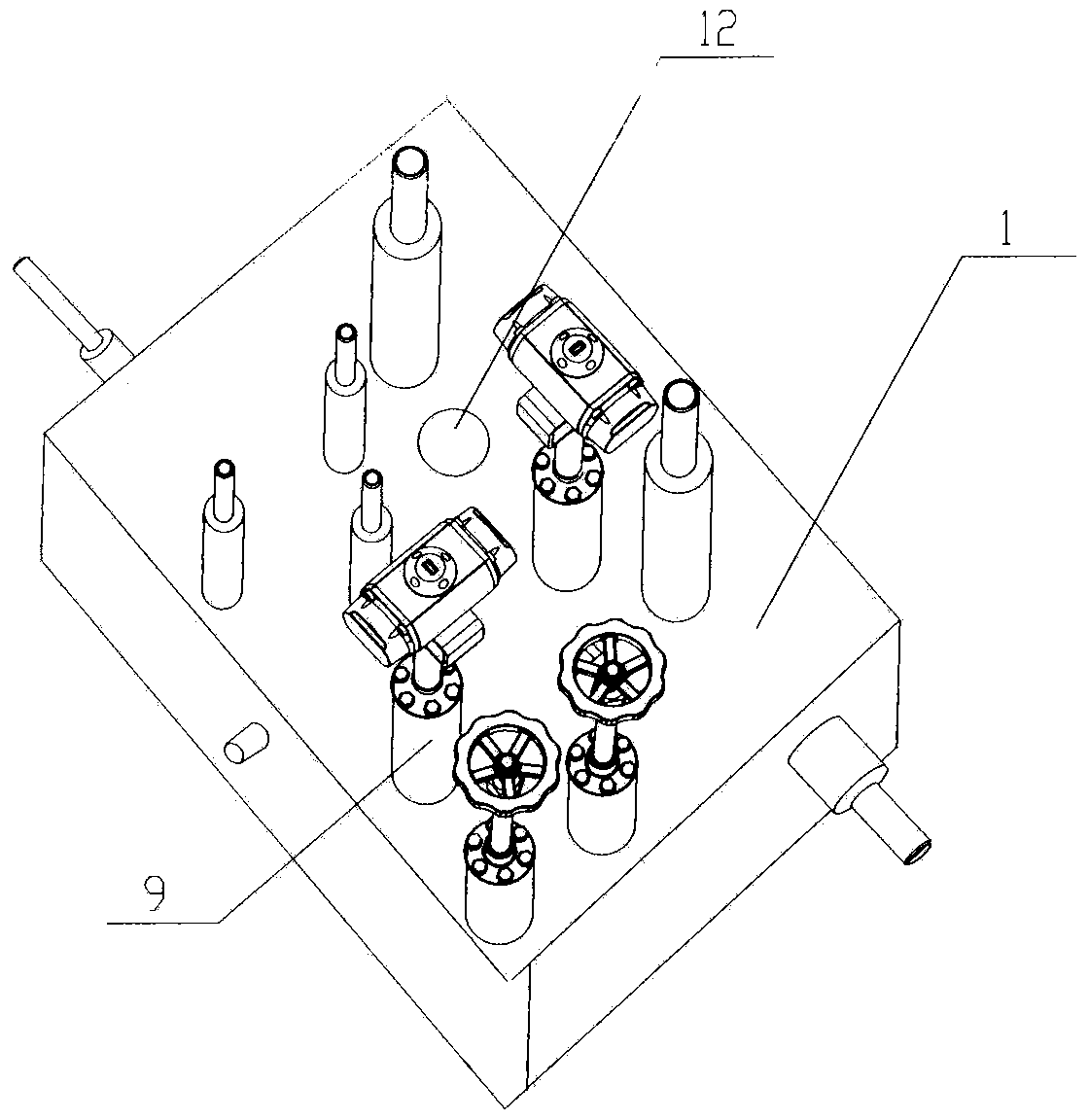

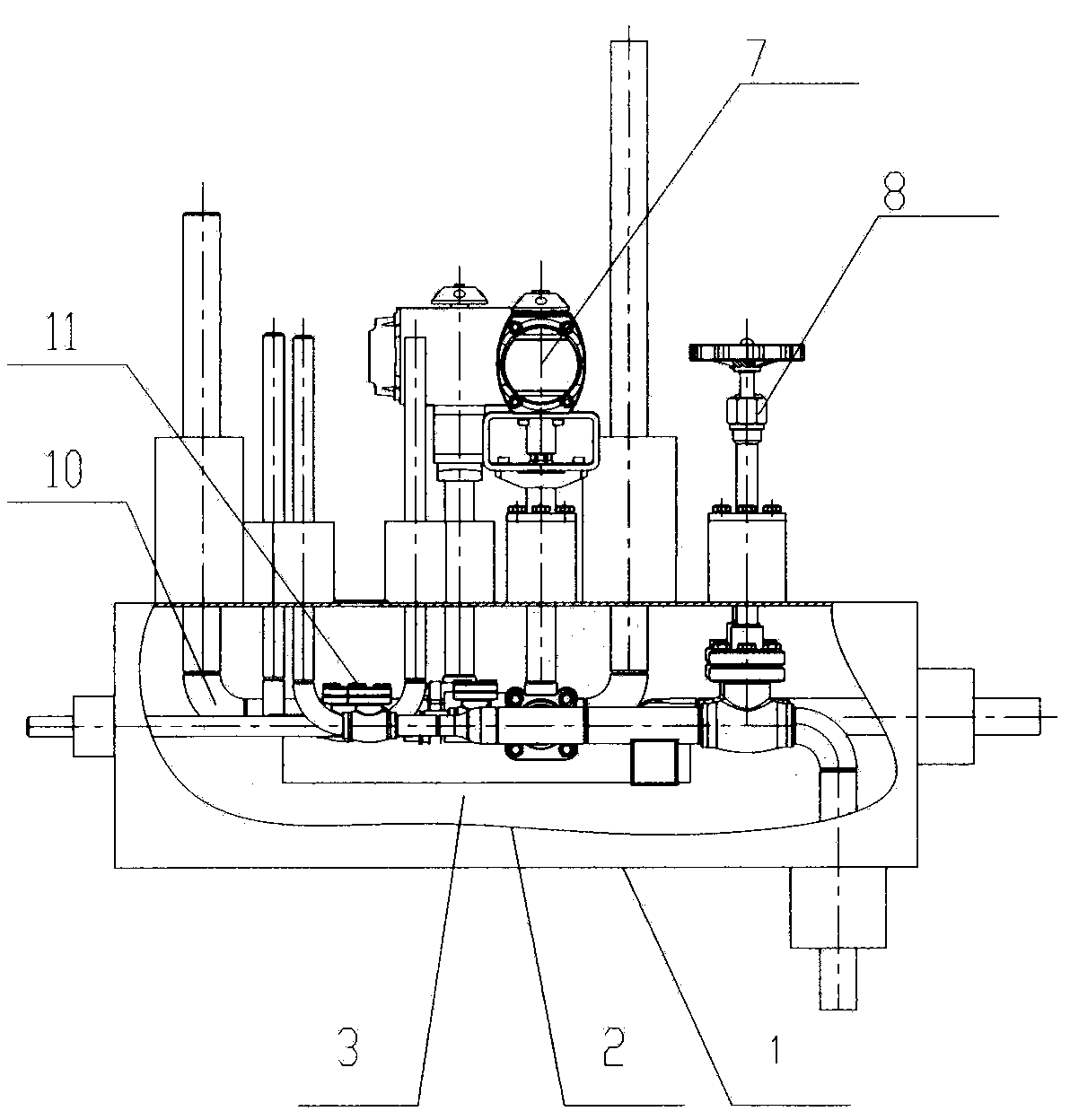

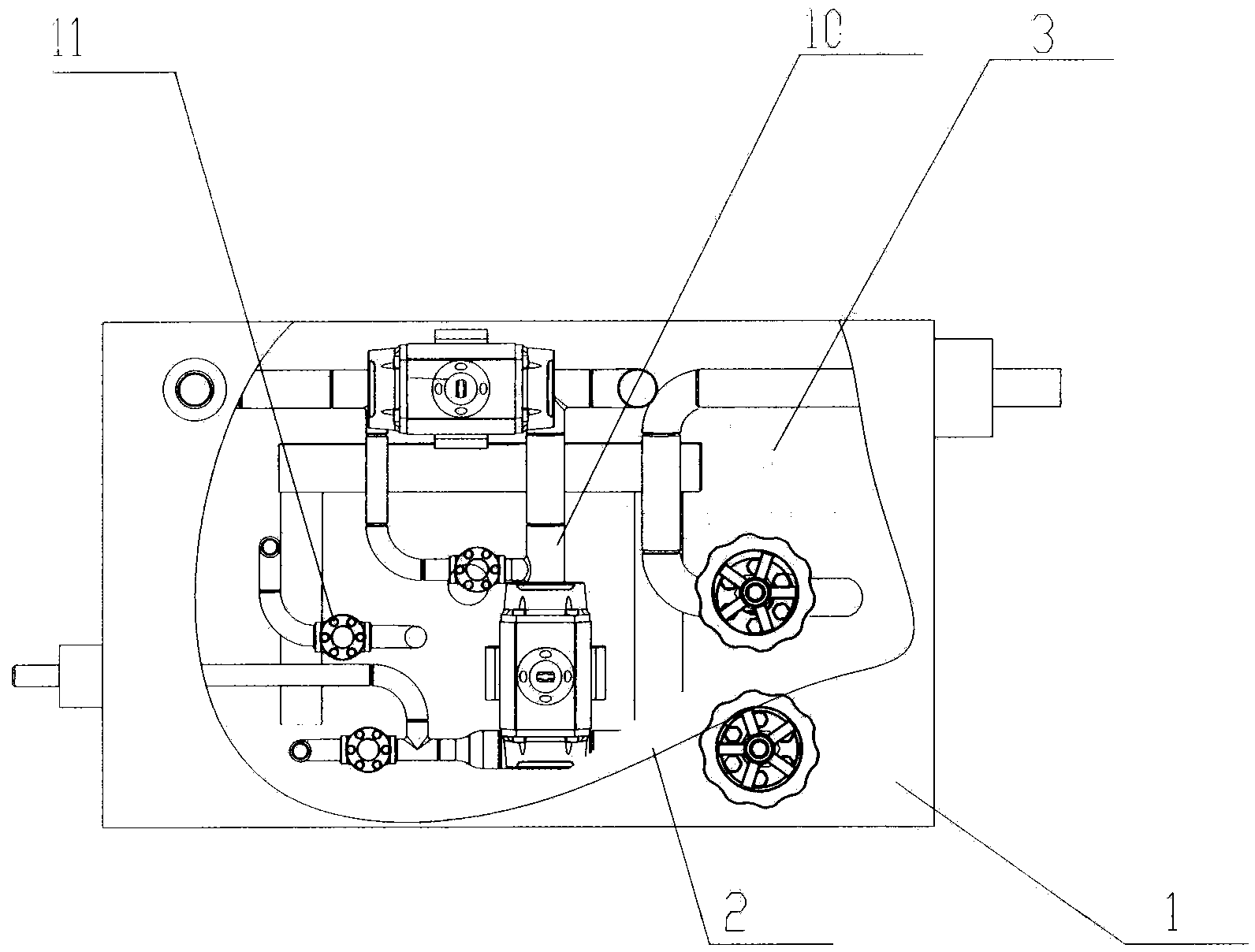

[0022] Examples:

[0023] Such as Figure 1 ~ Figure 4 Shown: The vacuum valve assembly box of an LNG dispenser disclosed in this embodiment includes a box body 1, in which a pipe 10 and a valve 11 are arranged, and the pipe 10 is connected to extend out of the box body 1. The overhaul pipe is characterized in that the box body 1 is a vacuum-sealed structure, the box body 1 is provided with a sandwich layer 2, and the inner wall of the sandwich layer 2 is a multi-layer structure formed by a heat insulating material, and the inner wall of the sandwich layer 2 and The outer wall of the box 1 forms a closed vacuum chamber, the vacuum chamber is evenly filled with pearl sand 3, the pipe 10 and the valve 11 are installed in the vacuum chamber, and the pipe 10 and the valve 11 are wrapped with Anti-radiation material. .

[0024] As one of the preferred solutions, a vacuum nozzle 4 is connected to the side wall of the box body 1, and a sand filter 5 and a glass fiber cloth 6 are sequen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap