Protective device of high-temperature chamber electric furnace

A box-type resistance furnace and protection device technology, which is applied in the direction of lighting and heating equipment, can solve the problems of affecting the quality of processing, high maintenance costs, deformation of the furnace bottom, etc., and achieve the effect of improving balance, convenient operation and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to save understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

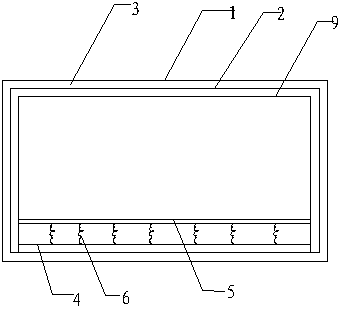

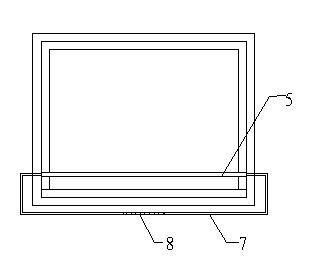

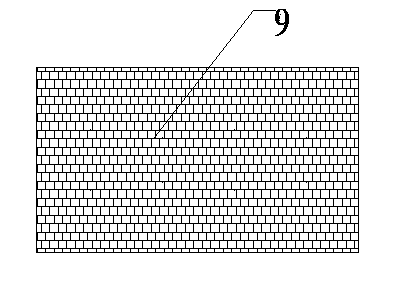

[0017] like Figure 1-3 As shown, the present invention is a protective device for a high-temperature box-type resistance furnace, which includes a furnace body 1 and a furnace 2 of a box-type resistance furnace, and a heat insulating layer 3 is arranged between the furnace body 1 and the furnace 2, The heat preservation effect is good, and the upper surface and both sides of the furnace 2 are respectively provided with a protective frame 9, and the protective frame 9 is a network frame made of high-temperature resistant stainless steel, which effectively protects the furnace 2 and prevents the workpiece from hitting and damaging the furnace 2 , to reduce the number of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap