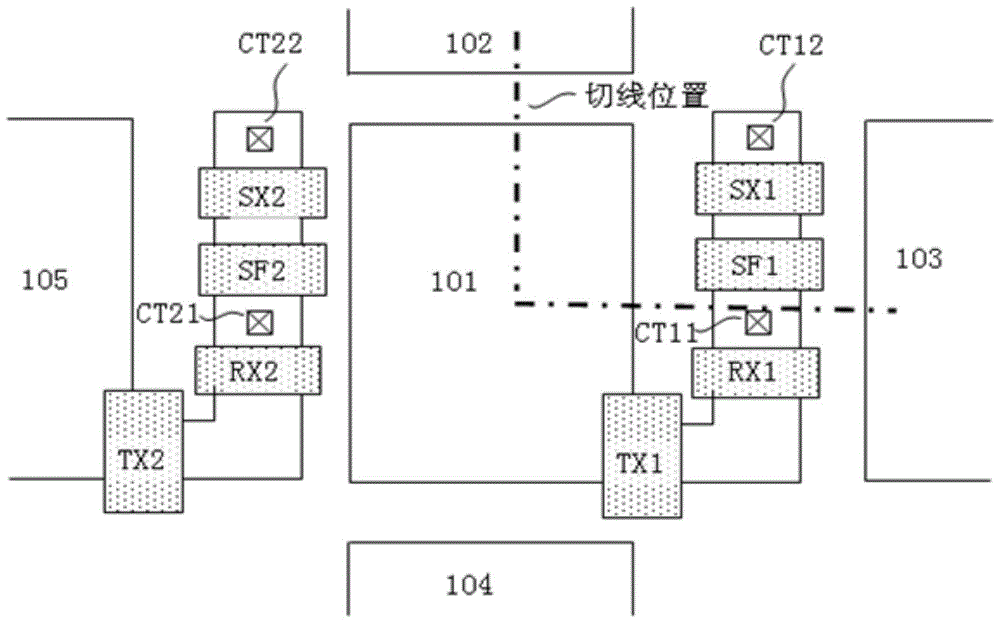

Image sensor pixel structure for preventing image dispersion and manufacturing method thereof

An image sensor and pixel structure technology, applied in radiation control devices and other directions, can solve the problems of increasing the number of saturated pixels, unable to reflect pixel signals, and reducing image quality, and achieve the effect of eliminating pixel color distortion and preventing image dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

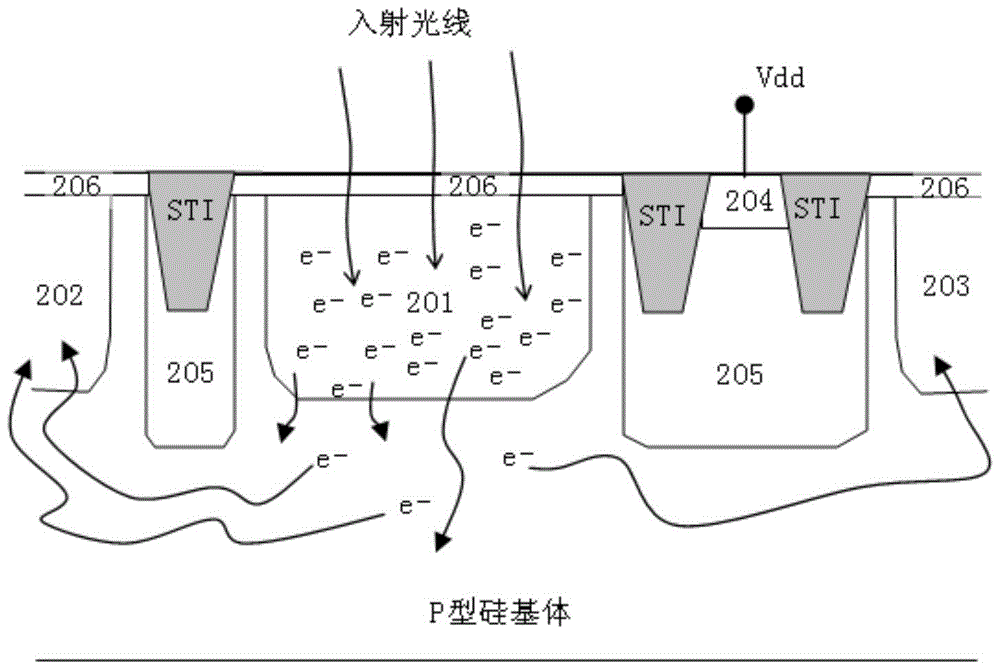

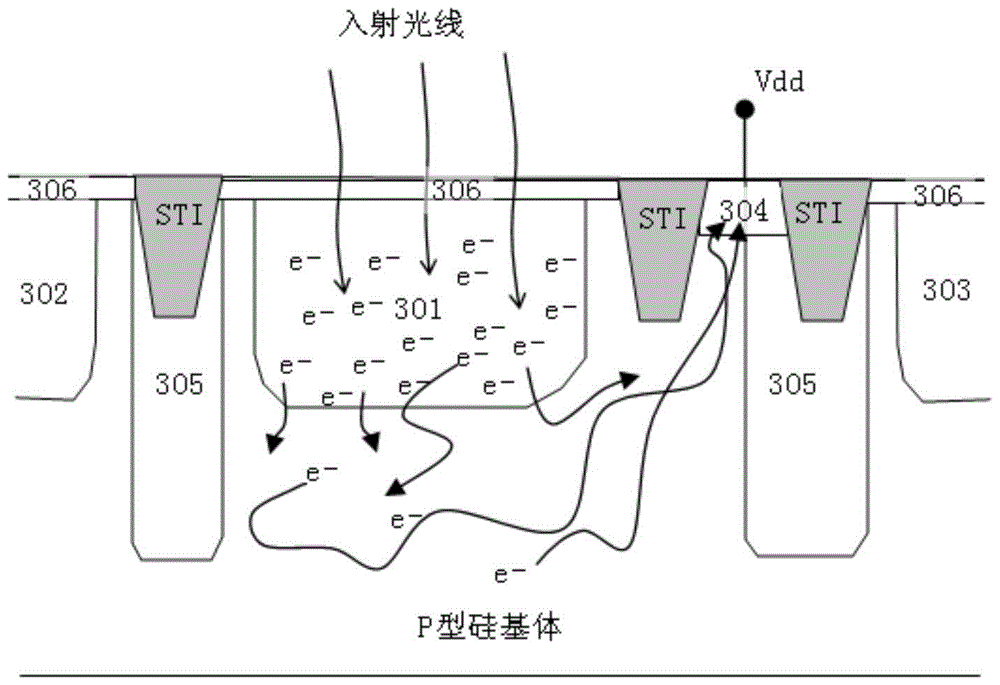

[0031] An embodiment of the present invention provides an image sensor pixel structure for preventing image dispersion, which at least includes a photodiode placed in a semiconductor substrate, a shallow trench isolation region arranged on one side of the photodiode, and a shallow trench isolation region arranged on the other side of the photodiode. Two shallow trench isolation regions and a transistor drain active region disposed between the two shallow trench isolation regions and connected to the power supply, wherein one shallow trench isolation region on one side of the photodiode, and one on the other side A deep P-type well region is provided on one of the two shallow trench isolation regions and part of the active region (not fully covered) at the drain end of the transistor, wherein the active region on the drain end of the transistor A deep P-type well region, which covers the shallow trench isolation region farther from the photodiode, and is not in contact with the ...

Embodiment 2

[0041] An embodiment of the present invention provides a method for manufacturing a pixel structure of an image sensor that prevents image dispersion. The specific process steps include Figure 4 ~ Figure 7 Steps shown:

[0042] 1) if Figure 4 As shown, after the STI process in the traditional CMOS process, an oxide layer 401 is grown on the surface of the semiconductor substrate as a process protection layer with a thickness of 10nm-12nm. This embodiment uses a P-type silicon substrate.

[0043] 2) if Figure 5 As shown, the photoresist is spin-coated and developed to open the predetermined P-type well injection region; the thickness of the photoresist is not less than 2.7um. The opening in the predetermined P-type well injection region includes: an opening facing a shallow trench isolation region on one side of the photodiode, another opening covering the shallow trench isolation region and part of the active region away from the photodiode, and not make contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com