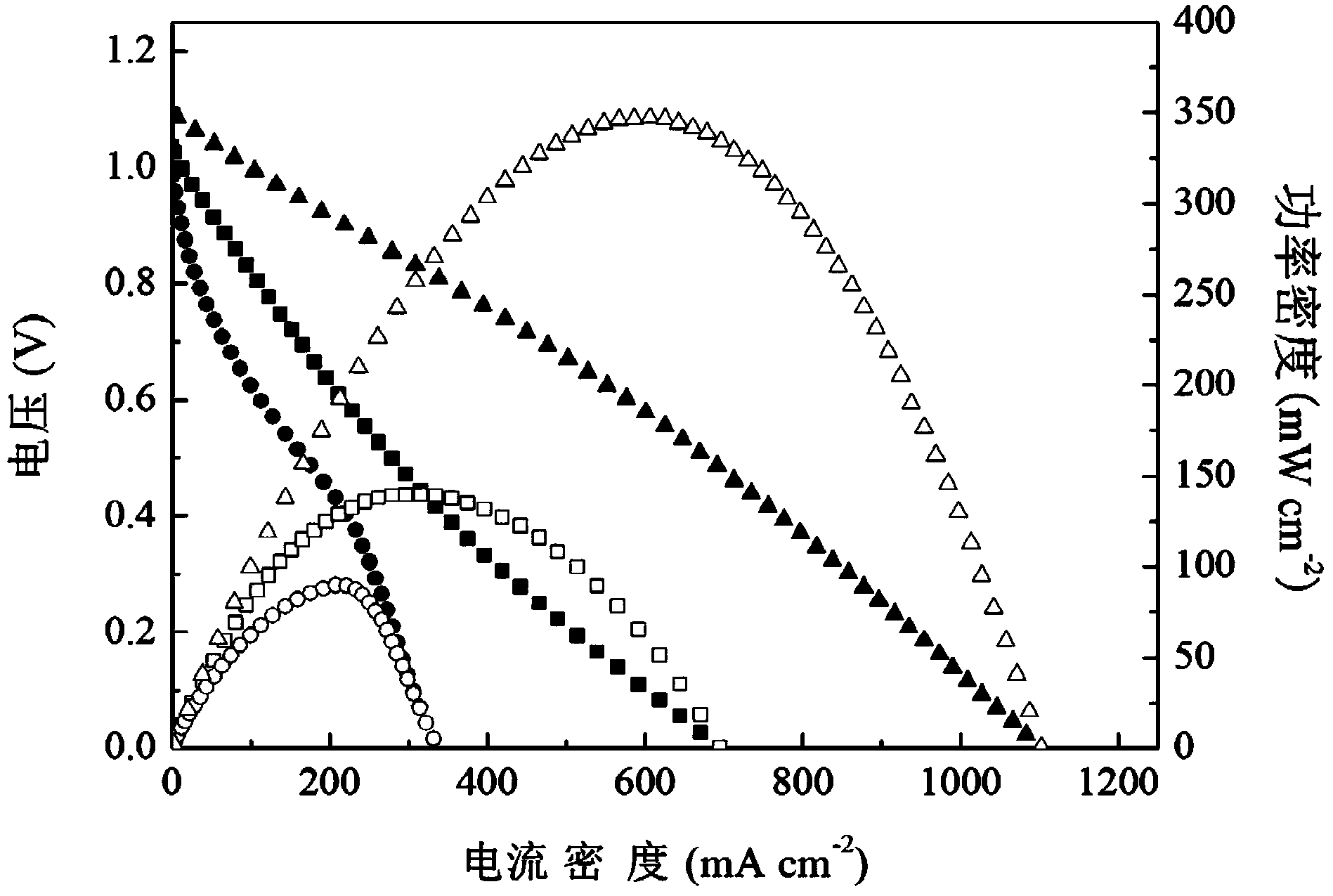

Method for preparing double-layered pore-structured solid oxide fuel cell (SOFC) anode by impregnation method

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, battery electrodes, structural parts, etc., can solve the problems of low electrochemical activity and uneven distribution of metal nickel nanoparticles, improve output performance, avoid significant The effect of agglomeration and maintaining the stability of the microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Embodiment 1: A method of preparing a solid oxide fuel cell anode with a double-layer pore structure by an impregnation method in this embodiment is carried out according to the following steps:

[0018] 1. Put 1-5 parts of 8YSZ powder and 1-5 parts of flour into an agate mortar and grind until they are evenly mixed to obtain mixed powder 1, and then put 0.14-0.22g of mixed powder 1 into a 13mm-diameter In a stainless steel mold, hold the pressure for 5-30s under a pressure of 100-300MPa to make a YSZ anode support with flour as a pore-forming agent;

[0019]2. Put 1-5 parts of 8YSZ powder and 1-5 parts of cassava flour into an agate mortar and grind them until they are evenly mixed to obtain mixed powder 2. Sieve and spread 0.02-0.1g of mixed powder 2 evenly on the surface of the YSZ anode support obtained in step 1 with flour as a pore-forming agent, apply a pressure of 300-500MPa and keep the pressure for 20-80s, take it out, and then put it in high temperature In a...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, the pressure is kept at 200 MPa for 15 seconds. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, a pressure of 400 MPa is applied and the pressure is maintained for 50 seconds. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com