Wheel hub code-printing system and online wheel hub code-printing method

A wheel hub and coding machine technology, which is applied to typewriters, printing devices, printing, etc., can solve the problems that the relative position cannot be adjusted, cannot be applied to different types of hubs, etc., and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

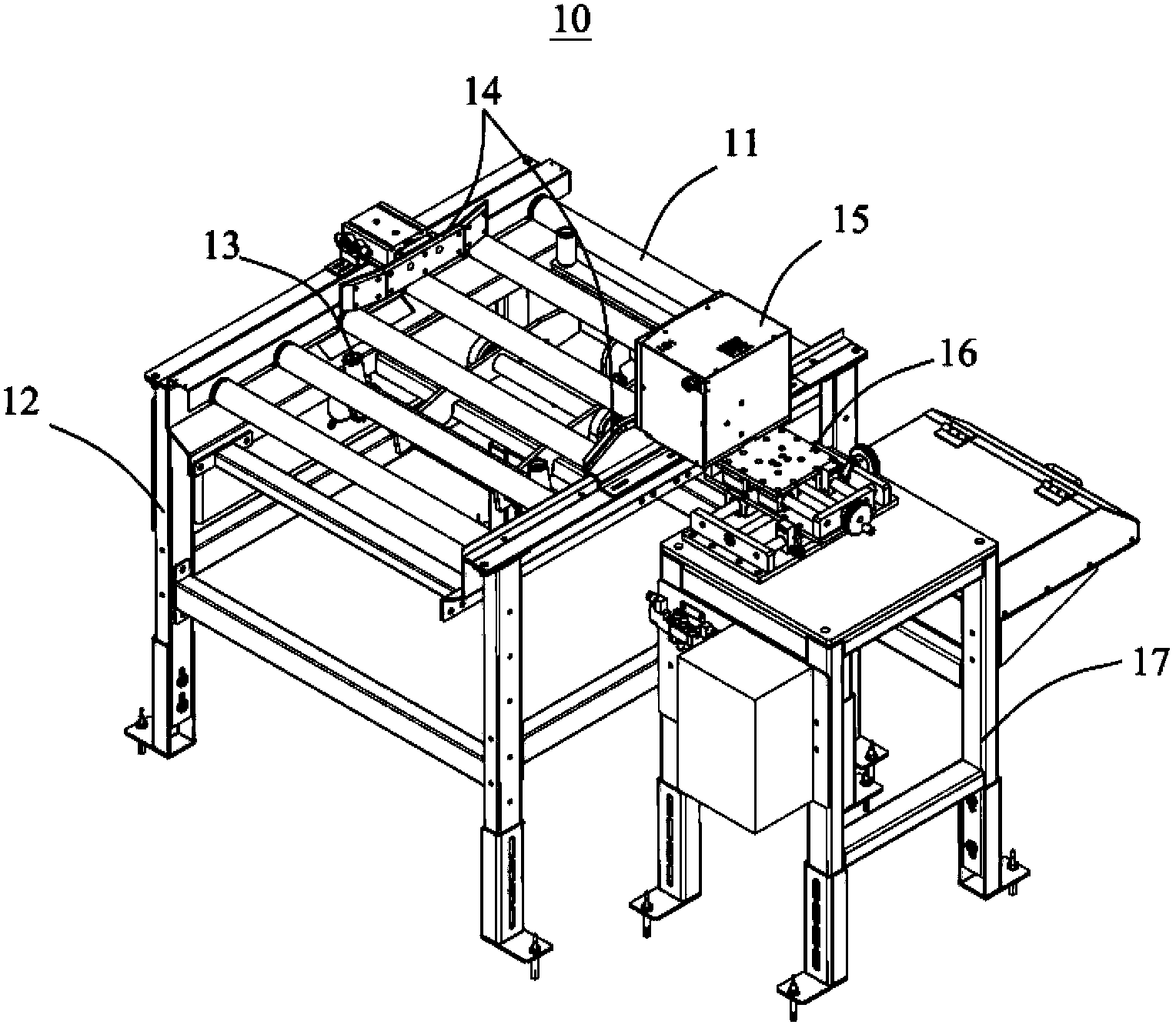

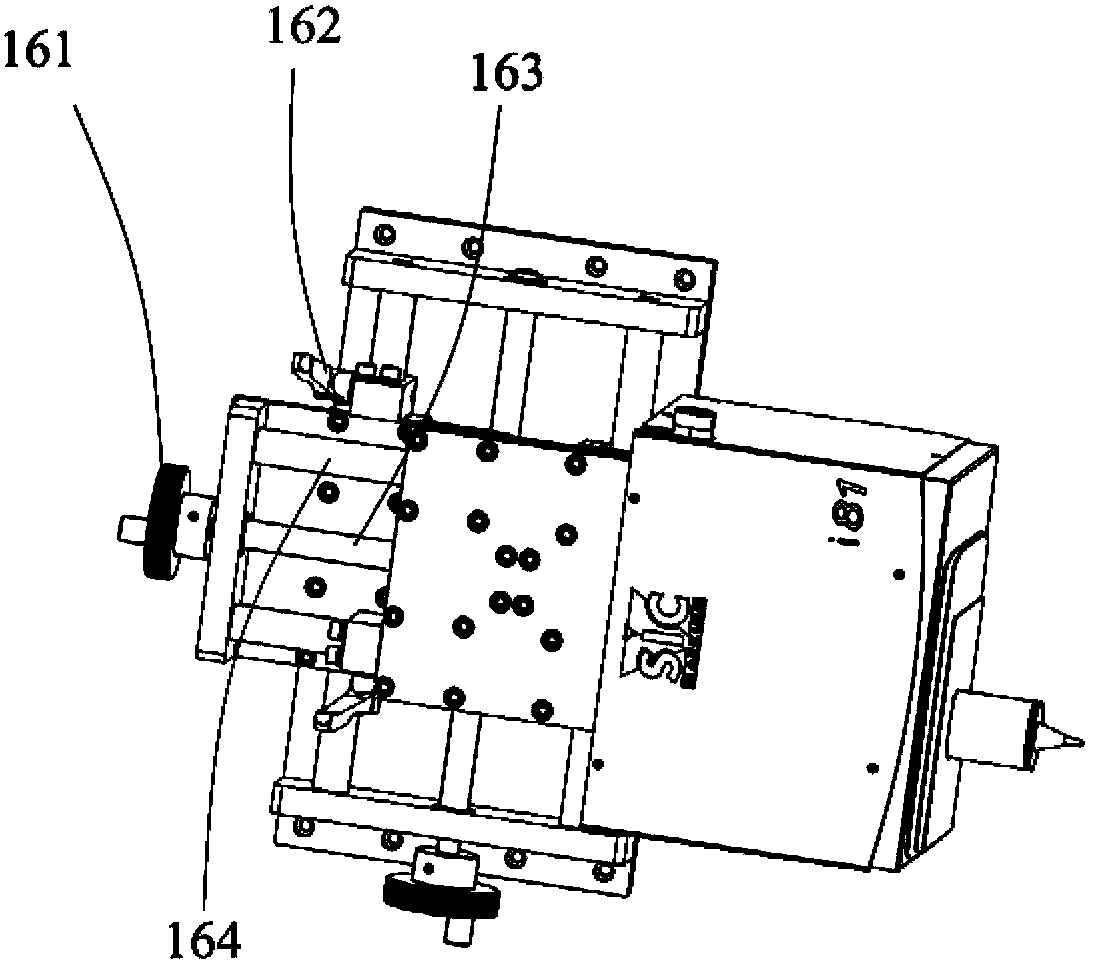

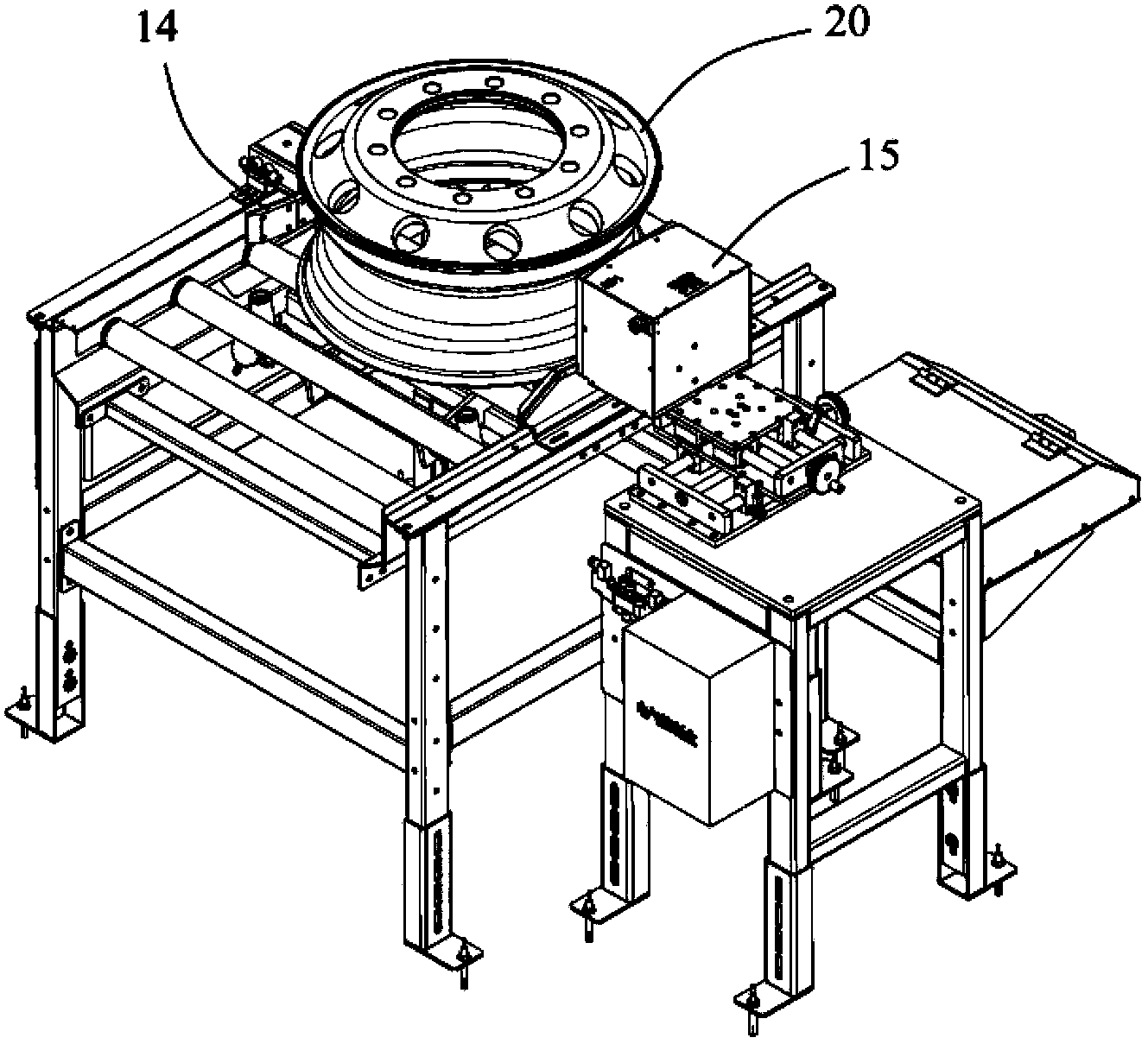

[0031] The embodiment of the present invention discloses a coding system for wheel hubs, which includes a conveying line for conveying the wheel hubs and a coding machine, and also includes a blocking mechanism for restricting the movement of the conveying line and a clamping mechanism for positioning the hubs. The card mechanism includes a first card loading mechanism and a second card loading mechanism, the first card loading mechanism and the second card loading mechanism are respectively located on both sides of the conveying line, and the first card loading mechanism and the second card loading mechanism The mechanism moves close to or away from and clamps and fixes the wheel hub, and the fixed position of the wheel hub is within the working range of the coding machine.

[0032] By arranging the first clamping mechanism and the second clamping mechanism capable of relative movement, the distance between the first clamping mechanism and the second clamping mechanism can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com