Annulated column cap embedded part and construction method thereof

A technology of embedded parts and ring columns, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as difficult arrangement, difficult to control the spacing and size of steel bars, and inability to install embedded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

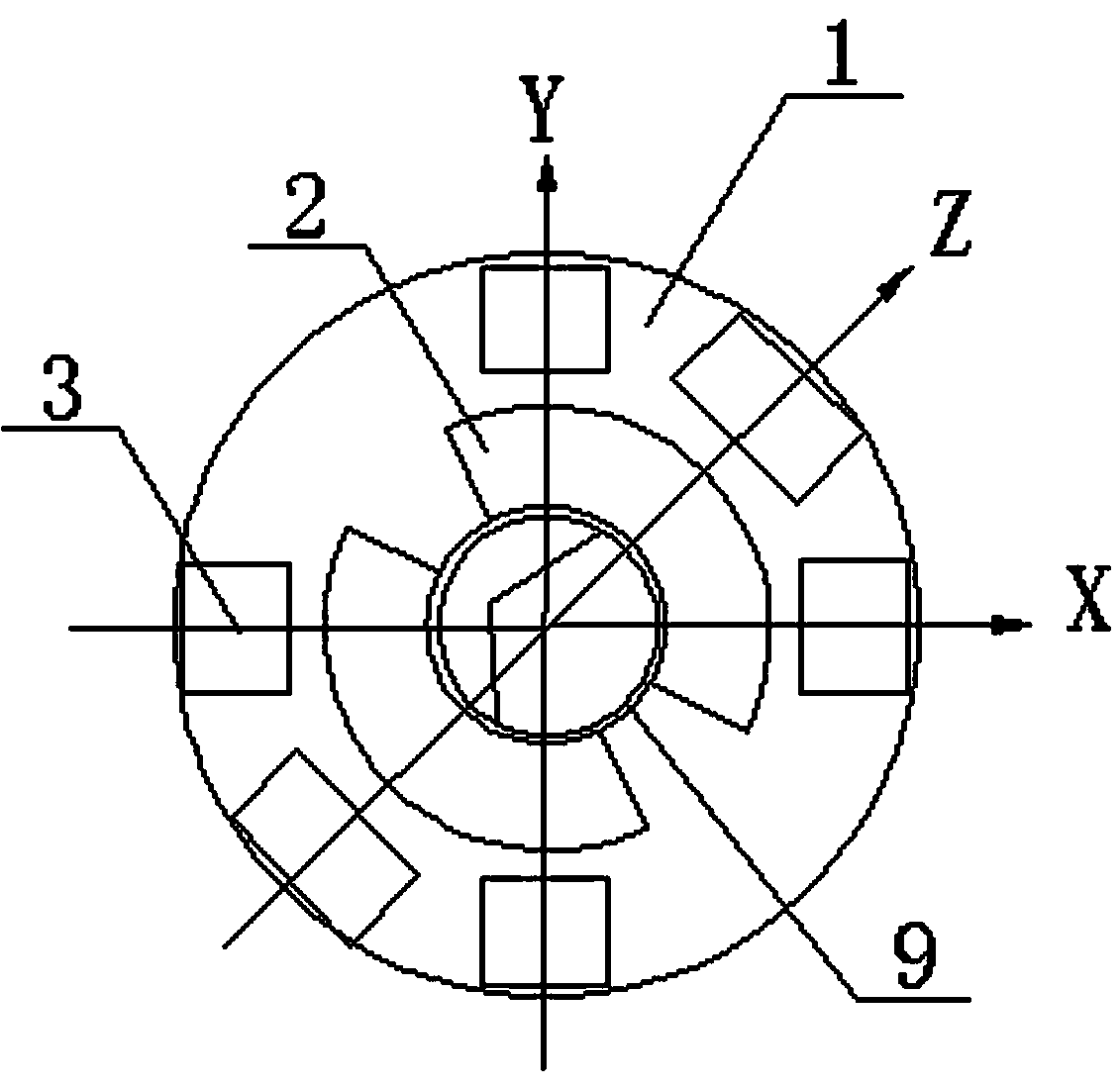

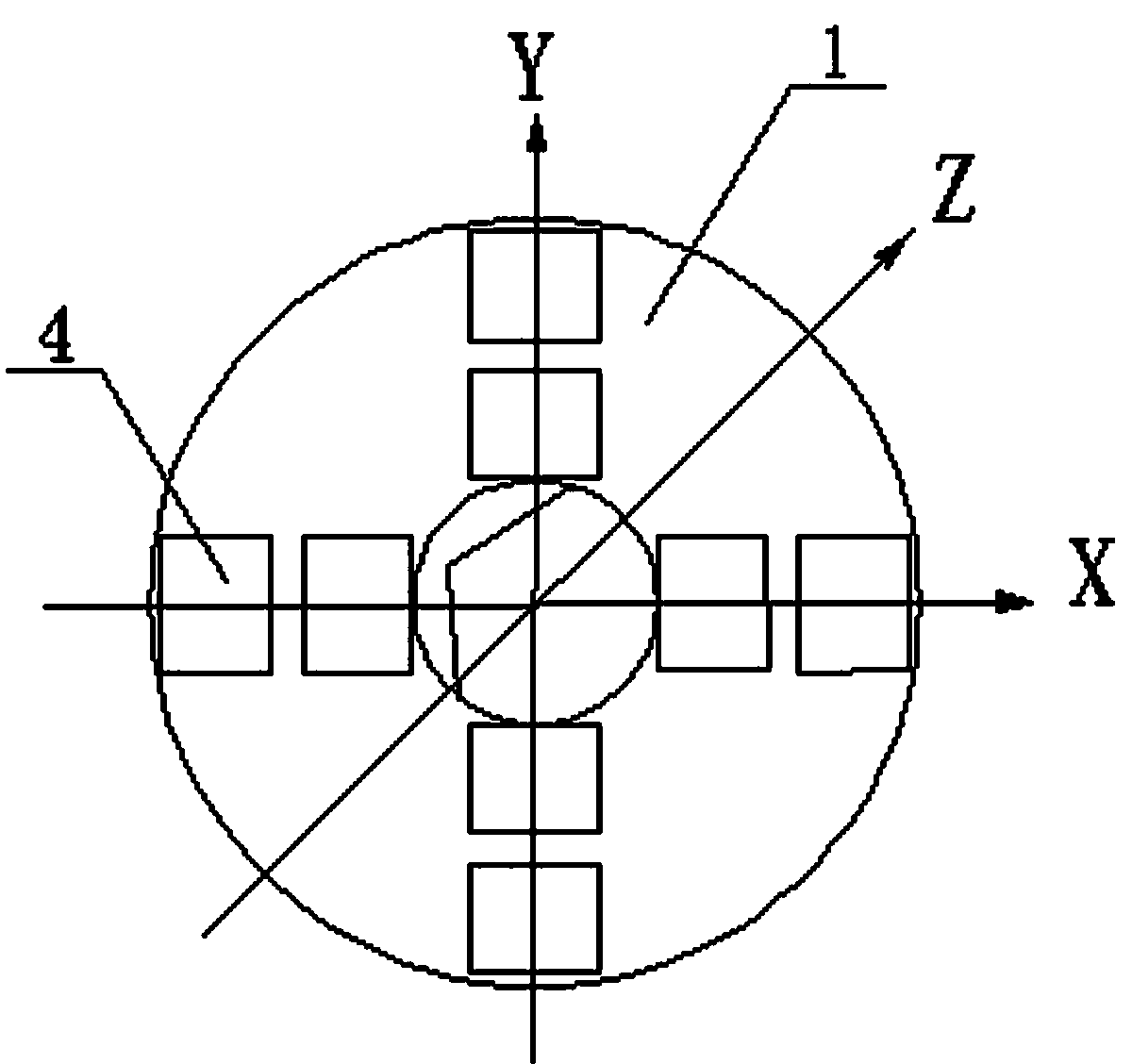

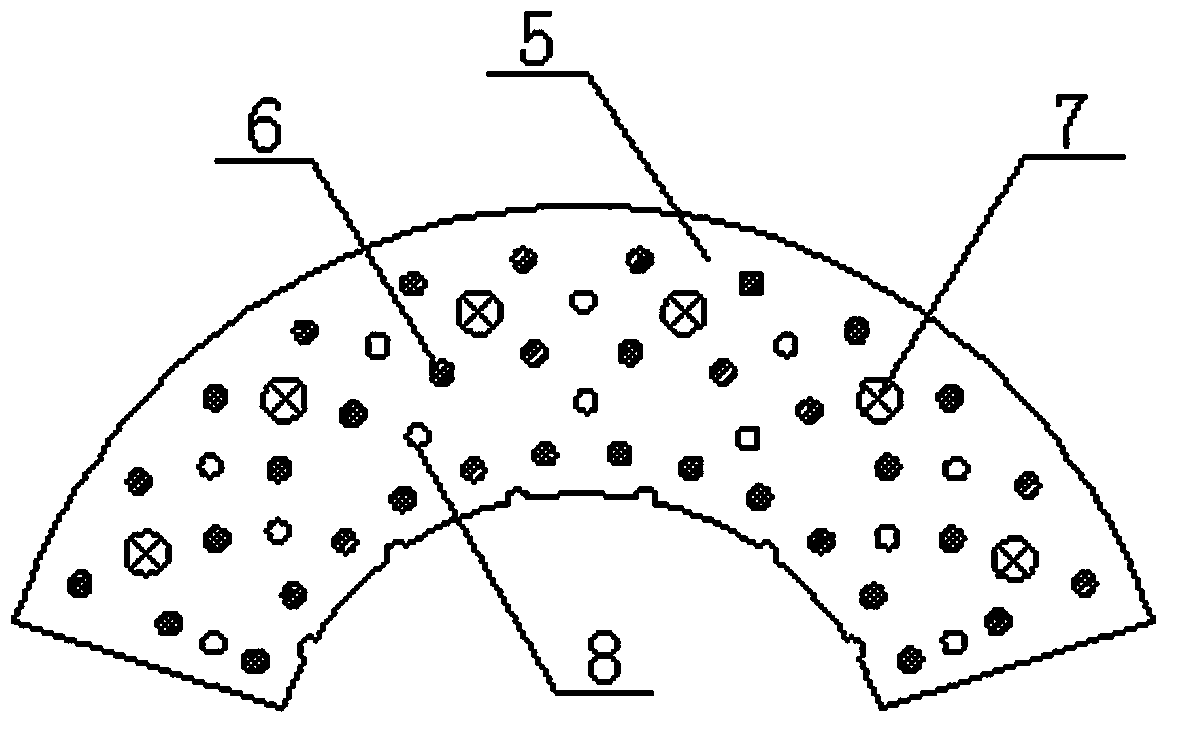

[0027] Attached below Figure 1-6 , to illustrate specific embodiments of the present invention.

[0028] A ring-shaped column cap embedded part of the present invention includes a pre-embedded steel plate and an anchor bar. The embedded part is embedded on the upper surface and the lower surface of the column cap. The shape of the embedded steel plate is the same, and the pre-embedded steel plate and the anchor bar are welded in a T shape; the arc-shaped upper embedded part embedded on the upper surface of the column cap is arranged symmetrically close to the inner ring, and the rectangular upper embedded part is arranged along the X-axis, Y-axis and Z-axis. The shaft is set on the extension line of the beam. The pre-embedded steel plate is provided with vibrating holes and vent holes. The vibrating holes and vent holes are evenly arranged. The radius of the vibrating hole is 80mm. Small round steel plate groove plugs of equal thickness and the same material are welded and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com